Derek Cohen (Perth Oz)

Established Member

Hi Pam

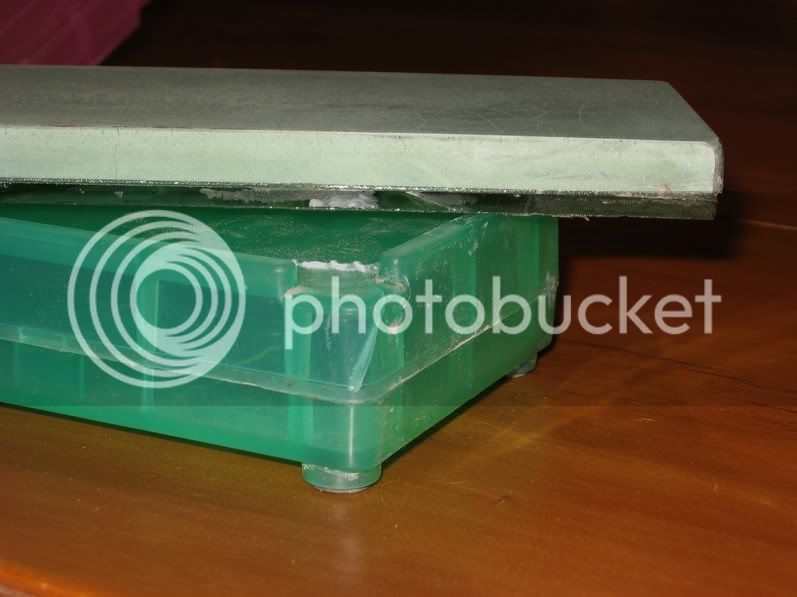

My sincere thanks for the most generous offer. I may take you up on it, but I must admit to being curious to find out what happens to "my" 8000 first (so I have just spent a little time laminating it in the interest of science! No going back now).

Just to clarify what So told me - he has sold new, unused Shaptons on eBay (he recently sold a 1000 and 2000 Professional series). However, my understanding was that he acquired these for himself, therefore he does not get in "stock" to re-sell on. He is a super nice guy and has been very happy to share his knowledge, especially on the Ubeaut forum.

http://www.woodworkforums.ubeaut.com.au/forumdisplay.php?s=&daysprune=&f=111

Regards from Perth

Derek

My sincere thanks for the most generous offer. I may take you up on it, but I must admit to being curious to find out what happens to "my" 8000 first (so I have just spent a little time laminating it in the interest of science! No going back now).

Just to clarify what So told me - he has sold new, unused Shaptons on eBay (he recently sold a 1000 and 2000 Professional series). However, my understanding was that he acquired these for himself, therefore he does not get in "stock" to re-sell on. He is a super nice guy and has been very happy to share his knowledge, especially on the Ubeaut forum.

http://www.woodworkforums.ubeaut.com.au/forumdisplay.php?s=&daysprune=&f=111

Regards from Perth

Derek