Arnt

New member

- Joined

- 30 Oct 2007

- Messages

- 4

- Reaction score

- 0

Hi, first post from me.

I live in Tondheim, Norway where I have a basement shop in my house. I build steel string guitars, arch top mandolins and occasionally some really odd instruments. I recently reorganized my workshop and took some pictures. Well, of course it is not actually finished, we all know these things are ever evolving projects. I am putting some more cabinets under the bench, installing I door between the two rooms, I still have to build the down draft table, finish the separate room for the DC and the ductwork etc. Details! (It adds up, I know, I know...)

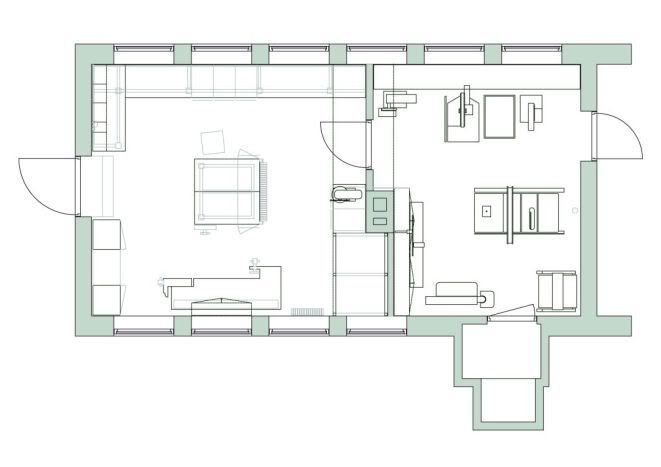

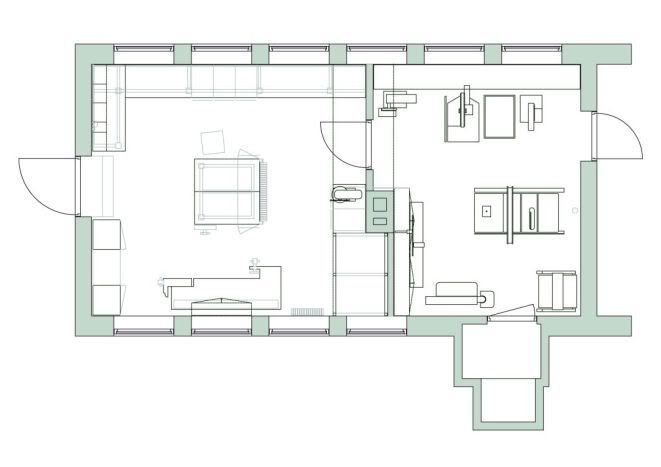

So here it is. The new shop consists of two separate rooms, one bench room and one machine room. The machine room is new; I used to have everything crammed into the room that is now the bench room. I wanted to separate the dust and debris of the big wood processing machines from the ‘clean’ work. The whole shop is 9 x 4,6 m (about 30’ x 15’).

Here’s the plan.

The shop is in a semi basement, and about half of the shop is below grade. I have a bit of daylight, mostly from north, and I oriented the benches so I can position my work to take advantage of the light in many different positions. I also put some insulation and OSB on the walls, built new benches and shelves. Most of it is recycled from the old shop, cabinets are leftovers from various house renos and the bench tops are solid beech from IKEA (cost the same as a double 20 mm plywood bechtop would have, believe it or not). The drill press is the only big power tool in this room.

In the bench room I have a central work station that I can work on all from all 4 sides.

A pipe clamp guitar holding vise is on one end, and clamps are stored along another side.

An old workbench is on one side. About the bench... they are very common in these parts, and this specimen could be 50 or 150 years old ; wooden bench screw are uncommon on more modern benches. I got it from a friend some year back, but I haven't had a chance to fix it up yet. Up here, these traditional benches are usually quite humble and utilitarian in their appearance, I have never seen any of 'trophy' Scandinavian style benches that exist in some other countries (especially the US). I'm going to flatten the top a bit, that's it. I have another (larger, but nicer) bench that I just didn't have room for any more.

The hand tool cabinet above it I quickly made from an discarded pine book case and some plywood. I like to put the tools away after use, but still have them easily accessible where they will be used so a normal clamshell type cabinet seemed like a good idea. These are more general woodworking tools than guitar making tools.

Here’s the bench along the opposite wall for routing, sanding, go bar clamping and so on. Sharpening station and 'wet work' on a high pressure laminate bench top at the far end.

Some more chisels above this bench

Here's how the chisel rack looks up close. With these slotted board holders there is always the danger of the chisel falling out if it's not seated properly. My solution was to recess a hole for the the ferrules so the chisel seats more securely. It is more important on the chisel rack over in the cabinet door of course, but you really don't want any falling chisels on any part of your work area!

Storage…

...and more storage

Woks in progress, routers and trimmers on a shelf below.

The only big power tool in the bench room is the drill press. It doesn't really produce a lot of dust, and it is handy to have it near the benches.

I haven’t finished the ductwork for the dust collector yet, and the machine room is a bit dusty. Anyways, here are a couple of snapshots. First the large bandsaw. This one is 24” and 3 phase motor, works wonderfully. I have a 12” too, (not pictured).

Some more heavy metal…

Here is the type of work I do. This is the headstock of a guitar bouzouki i finished last year.

Thanks for looking!

I live in Tondheim, Norway where I have a basement shop in my house. I build steel string guitars, arch top mandolins and occasionally some really odd instruments. I recently reorganized my workshop and took some pictures. Well, of course it is not actually finished, we all know these things are ever evolving projects. I am putting some more cabinets under the bench, installing I door between the two rooms, I still have to build the down draft table, finish the separate room for the DC and the ductwork etc. Details! (It adds up, I know, I know...)

So here it is. The new shop consists of two separate rooms, one bench room and one machine room. The machine room is new; I used to have everything crammed into the room that is now the bench room. I wanted to separate the dust and debris of the big wood processing machines from the ‘clean’ work. The whole shop is 9 x 4,6 m (about 30’ x 15’).

Here’s the plan.

The shop is in a semi basement, and about half of the shop is below grade. I have a bit of daylight, mostly from north, and I oriented the benches so I can position my work to take advantage of the light in many different positions. I also put some insulation and OSB on the walls, built new benches and shelves. Most of it is recycled from the old shop, cabinets are leftovers from various house renos and the bench tops are solid beech from IKEA (cost the same as a double 20 mm plywood bechtop would have, believe it or not). The drill press is the only big power tool in this room.

In the bench room I have a central work station that I can work on all from all 4 sides.

A pipe clamp guitar holding vise is on one end, and clamps are stored along another side.

An old workbench is on one side. About the bench... they are very common in these parts, and this specimen could be 50 or 150 years old ; wooden bench screw are uncommon on more modern benches. I got it from a friend some year back, but I haven't had a chance to fix it up yet. Up here, these traditional benches are usually quite humble and utilitarian in their appearance, I have never seen any of 'trophy' Scandinavian style benches that exist in some other countries (especially the US). I'm going to flatten the top a bit, that's it. I have another (larger, but nicer) bench that I just didn't have room for any more.

The hand tool cabinet above it I quickly made from an discarded pine book case and some plywood. I like to put the tools away after use, but still have them easily accessible where they will be used so a normal clamshell type cabinet seemed like a good idea. These are more general woodworking tools than guitar making tools.

Here’s the bench along the opposite wall for routing, sanding, go bar clamping and so on. Sharpening station and 'wet work' on a high pressure laminate bench top at the far end.

Some more chisels above this bench

Here's how the chisel rack looks up close. With these slotted board holders there is always the danger of the chisel falling out if it's not seated properly. My solution was to recess a hole for the the ferrules so the chisel seats more securely. It is more important on the chisel rack over in the cabinet door of course, but you really don't want any falling chisels on any part of your work area!

Storage…

...and more storage

Woks in progress, routers and trimmers on a shelf below.

The only big power tool in the bench room is the drill press. It doesn't really produce a lot of dust, and it is handy to have it near the benches.

I haven’t finished the ductwork for the dust collector yet, and the machine room is a bit dusty. Anyways, here are a couple of snapshots. First the large bandsaw. This one is 24” and 3 phase motor, works wonderfully. I have a 12” too, (not pictured).

Some more heavy metal…

Here is the type of work I do. This is the headstock of a guitar bouzouki i finished last year.

Thanks for looking!