You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Narex Chisels- Mini review

- Thread starter LuptonM

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Status

- Not open for further replies.

studders

Established Member

Yes, I managed to misread the gauge and the post. #-o

I agree that one is too small to have been marked as 6mm, unless I've made another BU the others seem within what I'd call acceptable. If I really wanted/needed a 6mm I would have sent it back, other wise I'd just live with it.

I agree that one is too small to have been marked as 6mm, unless I've made another BU the others seem within what I'd call acceptable. If I really wanted/needed a 6mm I would have sent it back, other wise I'd just live with it.

No skills":1vbnr24g said:fair point, perhaps the addition of 'approximate size' should be used when advertising items?? is there a defined standard that would cover a product like this? (like the british standard used for squares/squareness?)

yes there is a defined standard its called weights and measures and is policed by the trading standards office , they can make you remove the items for sale until they are happy that they meet their requirements.They will allow a small tollerence but if its measuring 5.2mm not 6mm they will insist it is re marked as 5mm.

All seems fair to me its there to help and protect us.

Jacob

What goes around comes around.

Phew common sense!clk230":3s7ysq53 said:No skills":3s7ysq53 said:fair point, perhaps the addition of 'approximate size' should be used when advertising items?? is there a defined standard that would cover a product like this? (like the british standard used for squares/squareness?)

yes there is a defined standard its called weights and measures and is policed by the trading standards office , they can make you remove the items for sale until they are happy that they meet their requirements.They will allow a small tollerence but if its measuring 5.2mm not 6mm they will insist it is re marked as 5mm.

All seems fair to me its there to help and protect us.

9.56mm and 13.41mm aren't too good either. Send em back.

Jims 0.51" half inch is more accurate (only 0.25mm out) and is acceptable IMHO as it is slightly over size rather than under.

Funny watching the usual suspects getting so casual about precision. Are they burning their bras too? :lol: :lol: Perhaps they should be encouraged to loosen up a bit, but where will it lead? :shock:

No skills

Established Member

Hmm educated twice in one night, must return to my cave.

I would certainly buy a set of narex chisels (and have been considering it for a while) and the size issue wouldnt bother me, BUT I do wonder - if I were making precise wooden items for a living if it would matter to me then.

:?:

I would certainly buy a set of narex chisels (and have been considering it for a while) and the size issue wouldnt bother me, BUT I do wonder - if I were making precise wooden items for a living if it would matter to me then.

:?:

£26.99 (£1.35 / count)

VEVOX® FFP2 Dust Mask - Set of 20 - Valved Face Masks - Respirator - Protection e.g. for Construction, Building Work, Sanding, Woodworking, Fine Dusts, Aersoles or Particles

SLSK Ventures GmbH (UK)

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

matthewwh

Established Member

Blimey,

This thread has tickled along a bit since I last looked!

If anyone has a 6mm measuring 5.2mm at the tip, (or anything else that is miles out) send it back and I will gladly replace it and cover all of the postage costs. I have never seen one that far out and if it proves to be so will ensure that it ends up being gently hammered into the centre of the production manager's desk. As I have explained before there should be a taper in the width over the length of the chisel - this is intentional and stops it from binding in the same way that the set on a saw prevents it from binding. 1mm of taper over the full length of a 16mm chisel is about right - proportionally applied to the smaller sizes.

Time for some facts to substantiate how accurate or inaccurate they are, as I'm probably the only one here with boxes of Narex chisels to measure and a factory fresh Moore & Wright dial caliper complete with inspection certificate, so I'll do the decent thing - here's the results for some mortice chisels chosen at random from the open boxes and measured at the tip:

8882 6mm: 5.95mm

8882 6mm: 6.05mm

8882 6mm: 6.00mm

8882 10mm: 10.06mm

8882 10mm: 10.08mm

8882 5mm: 5.02mm

8882 5mm: 5.09mm

8112 12mm: 12.02mm

8112 12mm: 11.92mm

8112 6mm: 6.03mm

8112 6mm: 6.03mm

My understanding of being out by a tenth would be a tenth of a mm not a tenth of the stated width. For a CNC mass produced chisel I'd still be happy if they got within two tenths of a mm as this is well within the capacity of the home user to tune the mortice chisel to the plough iron or vice versa for combined operations. I'd certainly question whether a hand grinder making mortice chisels 100 years ago would have reliably got anywhere near as close as this. I wouldn't expect today's hand grinders to achieve this level of accuracy in the width of a chisel and they have the advantage of experience, having not died of silicosis before they hit 30.

Expecting metric chisels to conform to imperial measurements and then berating them for being inaccurate is just plain silly. If people want imperial ones that's no problem at all, they already make them for the American market and I would be delighted to stock them if the demand is there.

If anyone feels like putting the calipers on any of the other mortice chisels on the market, LN, Sorby etc please feel free to post your results.

This thread has tickled along a bit since I last looked!

If anyone has a 6mm measuring 5.2mm at the tip, (or anything else that is miles out) send it back and I will gladly replace it and cover all of the postage costs. I have never seen one that far out and if it proves to be so will ensure that it ends up being gently hammered into the centre of the production manager's desk. As I have explained before there should be a taper in the width over the length of the chisel - this is intentional and stops it from binding in the same way that the set on a saw prevents it from binding. 1mm of taper over the full length of a 16mm chisel is about right - proportionally applied to the smaller sizes.

Time for some facts to substantiate how accurate or inaccurate they are, as I'm probably the only one here with boxes of Narex chisels to measure and a factory fresh Moore & Wright dial caliper complete with inspection certificate, so I'll do the decent thing - here's the results for some mortice chisels chosen at random from the open boxes and measured at the tip:

8882 6mm: 5.95mm

8882 6mm: 6.05mm

8882 6mm: 6.00mm

8882 10mm: 10.06mm

8882 10mm: 10.08mm

8882 5mm: 5.02mm

8882 5mm: 5.09mm

8112 12mm: 12.02mm

8112 12mm: 11.92mm

8112 6mm: 6.03mm

8112 6mm: 6.03mm

My understanding of being out by a tenth would be a tenth of a mm not a tenth of the stated width. For a CNC mass produced chisel I'd still be happy if they got within two tenths of a mm as this is well within the capacity of the home user to tune the mortice chisel to the plough iron or vice versa for combined operations. I'd certainly question whether a hand grinder making mortice chisels 100 years ago would have reliably got anywhere near as close as this. I wouldn't expect today's hand grinders to achieve this level of accuracy in the width of a chisel and they have the advantage of experience, having not died of silicosis before they hit 30.

Expecting metric chisels to conform to imperial measurements and then berating them for being inaccurate is just plain silly. If people want imperial ones that's no problem at all, they already make them for the American market and I would be delighted to stock them if the demand is there.

If anyone feels like putting the calipers on any of the other mortice chisels on the market, LN, Sorby etc please feel free to post your results.

unra159

Member

matthewwh":12xbijci said:Hi Marc,

...

There should be a very slight taper in the width of the blades from front to back so you will get different width measurements at different points up the blade. Its barely noticeable, maybe half a mm to a mm over the entire length, but with that and the slight taper on the sides it's enough to prevent them from behaving like a nail and sticking in the timber.

...

If you take a closer look at the photos you'll notice that measurement was taken somewhere in the middle of the blade.

Given the fact that the blades are slightly tapered along their length (see quote) the reading has to be less than the stated width of the chisel.

I happen to own four of these and as far as I remember they are pretty accurate measured at the cutting edge.

I checked it simply out of curiosity after I read Marc's review earlier this year.

When I tried to check again today I noticed the battery of my calliper is dead. Will get a new one tomorrow.

regards

Thorsten

jimi43

Established Member

How VERY dare your Matthew!!! :mrgreen:

All my Sorbys...no matter who was the brother...are accurate to within a few microns!

How else would they get precise mortices cut to fit the precise tenons that they made way back then....

I do hope you will be throwing those not absolutely accurate in the bin from now on instead of sending them out to poor unsuspecting eeegits!! :mrgreen: :mrgreen: :mrgreen:

Jim

PS....notice how I freely scatter the mortice/mortise words so as to prevent further pedants from gaining fodder for their armoury!!! :wink:

All my Sorbys...no matter who was the brother...are accurate to within a few microns!

How else would they get precise mortices cut to fit the precise tenons that they made way back then....

I do hope you will be throwing those not absolutely accurate in the bin from now on instead of sending them out to poor unsuspecting eeegits!! :mrgreen: :mrgreen: :mrgreen:

Jim

PS....notice how I freely scatter the mortice/mortise words so as to prevent further pedants from gaining fodder for their armoury!!! :wink:

unra159

Member

I really have to get faster writing in English :wink:

Thorsten

Thorsten

matthewwh

Established Member

They could always have fitted the tenon to the mortice, or is that too much lateral thinking?

The Oxford English Dictionary accepts either spelling, which fuggers up those wishing to be different nicely!

The Oxford English Dictionary accepts either spelling, which fuggers up those wishing to be different nicely!

Jacob

What goes around comes around.

Right so they are accurate after all and our OP just measured them wrongly! That's OK then :roll: . Are you reading this LuptonM? its all your fault.

You'll be pleased to have read here that Narex fans couldn't give a monkeys what width they are. I thought they had undergone some sort of paradigm shift but it seems not. Pity.

You'll be pleased to have read here that Narex fans couldn't give a monkeys what width they are. I thought they had undergone some sort of paradigm shift but it seems not. Pity.

LuptonM

Established Member

As I remember i tried to measure the width at the bottom. I think they were about 0.2mm smaller at the top face. I don't think the actual size matters unless you're using it with a combination of router bits. Edit: Didn't realize they are tapered in length as well as width

I'll remeasure when I get home (about 3 weeks). Please note I've also become much more proficient at sharpening than when this review thingy was done

I'd quite like to try Ray Iles mortise chisels as I think I may prefer the pick sticker design. However they are much more expensive and probably wouldn't make any difference to the quality of the work produced- ie more of an indulgence

I'll remeasure when I get home (about 3 weeks). Please note I've also become much more proficient at sharpening than when this review thingy was done

I'd quite like to try Ray Iles mortise chisels as I think I may prefer the pick sticker design. However they are much more expensive and probably wouldn't make any difference to the quality of the work produced- ie more of an indulgence

bugbear

Established Member

Jacob":1bjlwa60 said:And I'm happy to explain - you have picked up some bad habits!bugbear":1bjlwa60 said:....

Yebbut, you set the mortise gauge to the mortise chisel; thus the mortise is automatically the right size, made in a single pass of cuts, and you were going to have to cut the tenon in two separate line anyway, so there's no extra effort. Works for me, but if you have counter examples, I'm happy to listen.

If you are doing a lot of stuff, say 5 windows with glazing bars, you could have something like 100 or so M&Ts to cut. You set your gauge to 1/2" and mark all your mortices and all your tenons. You can then put the gauge away. You then cut all your mortices with a 1/2" chisel, and all your tenons to the lines you have made. That's all there is to it.

If you have an odd sized chisel and set the gauge accordingly the M&Ts will fit but other details may be out of line.

Er. Yes. That's the method I use too. My tenons fit nicely. Could you (please) expand on these "other details". The MT marking and cutting process is well understood, and doesn't bear belabouring. You mentioned a shoulder detail in a window M & T. That would be of interest.

Or if you swap odd sized chisel halfway through you may hit problems.

Yes - swapping mortise chisels to a different size would be very foolish, and cause trouble. Why would anyone ever do that? Straw man. methinks.

There was an interesting article on the theme of absolute versus "matched" sizes by an expert in 18th C woodworking, but I can't lay my hand on it right now. I'll try to find it.

BugBear

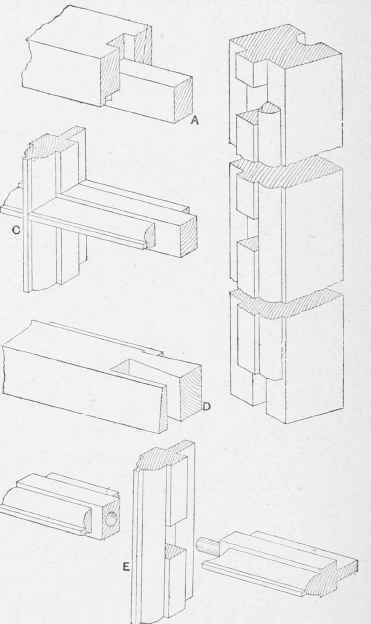

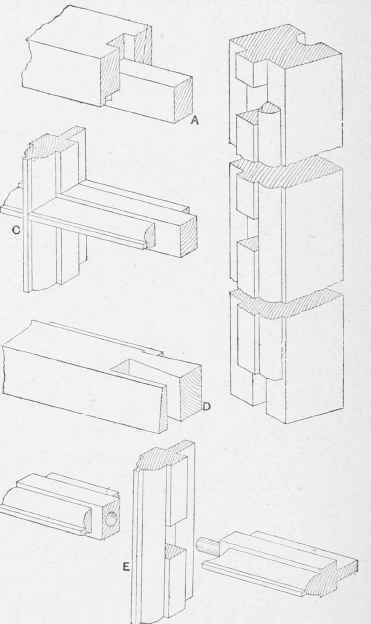

I hesitate to prolong a thread which has lurched around like this one has, but in the general melee there was an interesting point which deserves to be clarified. Sometimes, mortice and tenon joints will need to be made which match a pre-set dimension. This happens in traditional window making. I happened across this illustration which I hope will help:

To make the mortice for the tenon marked A to fit into (or the one at E) you need a chisel of the same width as the plain, flat bit of the moulding. If you were repairing an old window which had been made in a time of imperial sized tools, and the width was (say) half an inch, you would need a half inch chisel, not a 12mm one.

I would imagine that joiners would have liked to stick with standard sizes, so they didn't have to re-equip with new planes, chisels and sticking boards.

If you were making the whole thing by hand from new, you could design the dimensions to match the tools that you have.

To make the mortice for the tenon marked A to fit into (or the one at E) you need a chisel of the same width as the plain, flat bit of the moulding. If you were repairing an old window which had been made in a time of imperial sized tools, and the width was (say) half an inch, you would need a half inch chisel, not a 12mm one.

I would imagine that joiners would have liked to stick with standard sizes, so they didn't have to re-equip with new planes, chisels and sticking boards.

If you were making the whole thing by hand from new, you could design the dimensions to match the tools that you have.

Jacob

What goes around comes around.

That's it. Thanks for that it saves me having to explain yet another thing to BB,* which can take up such a lot of time!

If you don't have a 1/2' mortice chisel you either have to alter the whole design to match the chisel or end up with a funny little inconvenient shoulder detail with every M&T, and there may be hundreds in a common job.

1/2" mortice chisels usually are 1/2" and you can scale off your gauge setting instead of matching it to a chisel.

NB I did quite a few doors and windows entirely by hand when I started out, using a modern Marples sash mortice chisel (not unlike the Narex but with a much better handle - yellow plastic) as I couldn't afford a proper one and ebay hadn't been invented.

*Mind you he does listen, sometimes:

If you don't have a 1/2' mortice chisel you either have to alter the whole design to match the chisel or end up with a funny little inconvenient shoulder detail with every M&T, and there may be hundreds in a common job.

1/2" mortice chisels usually are 1/2" and you can scale off your gauge setting instead of matching it to a chisel.

NB I did quite a few doors and windows entirely by hand when I started out, using a modern Marples sash mortice chisel (not unlike the Narex but with a much better handle - yellow plastic) as I couldn't afford a proper one and ebay hadn't been invented.

*Mind you he does listen, sometimes:

:lol: :lol:bugbear":v42hiiy7 said:...Er. Yes. That's the method I use too....

Jacob

What goes around comes around.

For one yes, for one hundred, not bloody likely!Pete Maddex":1hd3yoxh said:I see you can only make a mortice the same width as the chisel, you can't pair the sides slightly wider.

...

Pete

Dodge

Established Member

Pete Maddex":3ihzftzn said:Jacob

I would reply but you are wearing me out, I will just go along with every thing you say, you are right, you are right, your are right....

My heart sinks when I see a reply from you.

Pete

=D> =D> Hear Hear !!!!!

- Status

- Not open for further replies.