This was going to be a slow project, but covid sped it up a bit. Dug out the hole over several weeks last year, ( around 2ft deep at the back and began filling with hardcore, from a garden path and some friends walls and building work. and once complete, will start the same again on the oposite side of the garden, with the use of office, bar, garden summer house type of thing.

Only came across one root from the willow, thats been removed, the root that is, not the tree.

Was never going to be done quick, then covid strikes and due to spending a lot of time in the garden my 4 and 6 year old, kept playing in the hardcore out of bordem, so got 12t of mot type one, used 9ish and made the area safer to them, roll on not spending anything on drink and eating out, in went some sand , dpc, rebar and 3.5M3 of pumped in concrete.

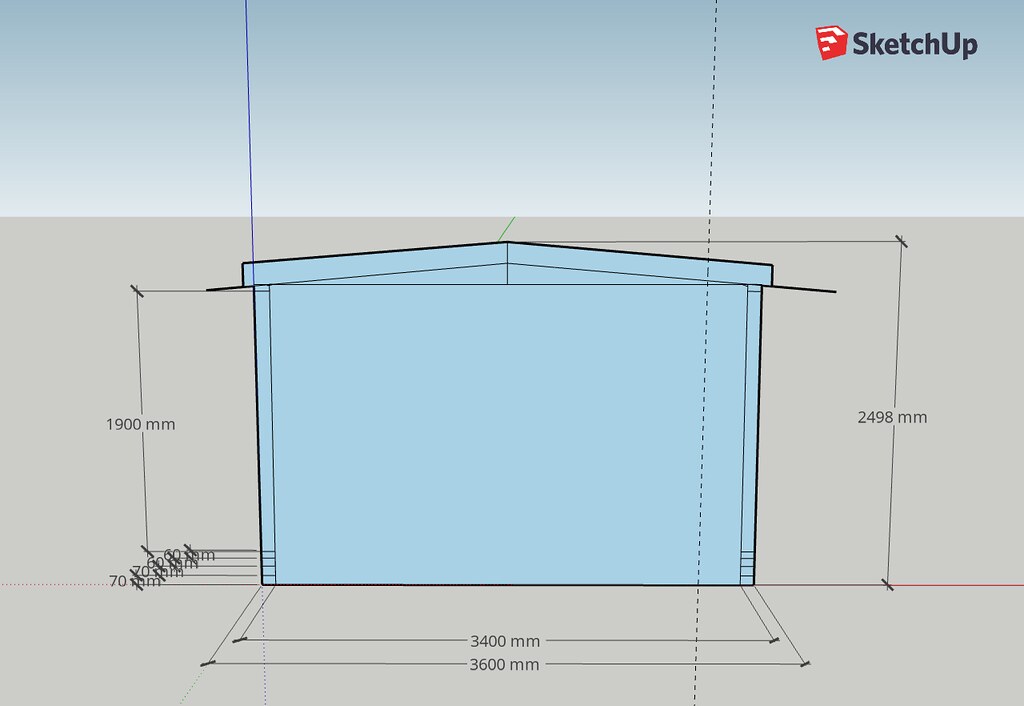

So now i have this 3.6 x 7m x 150mm base, below 30M2 but well within 1m of the boundrys, so is getting the suitable fireproofing, cladding in hardie or cedral board.

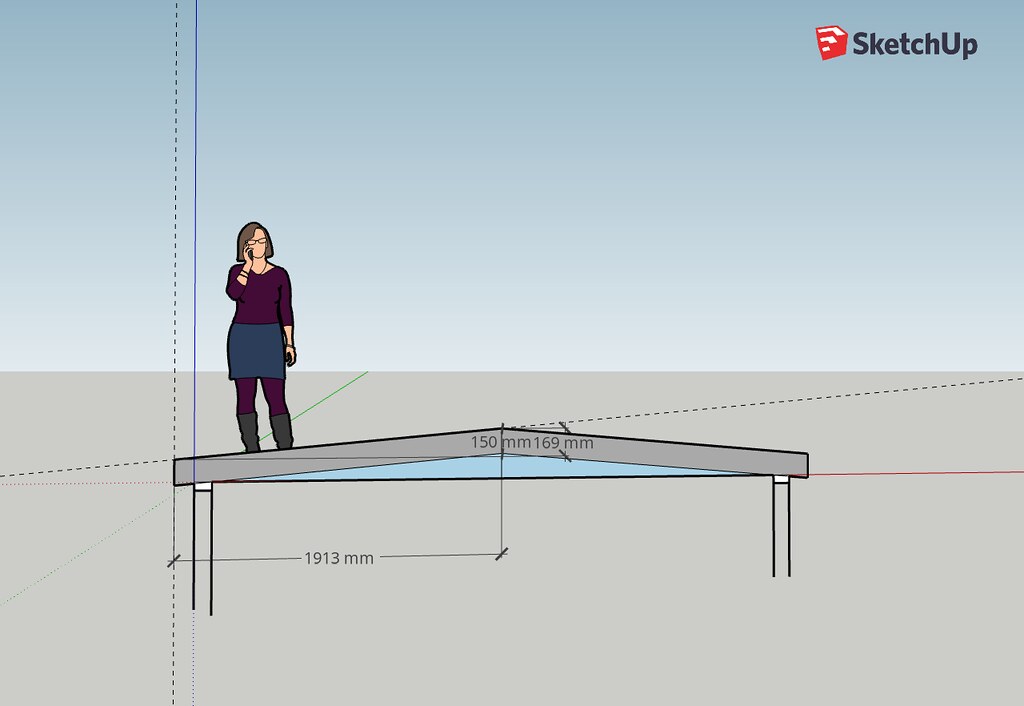

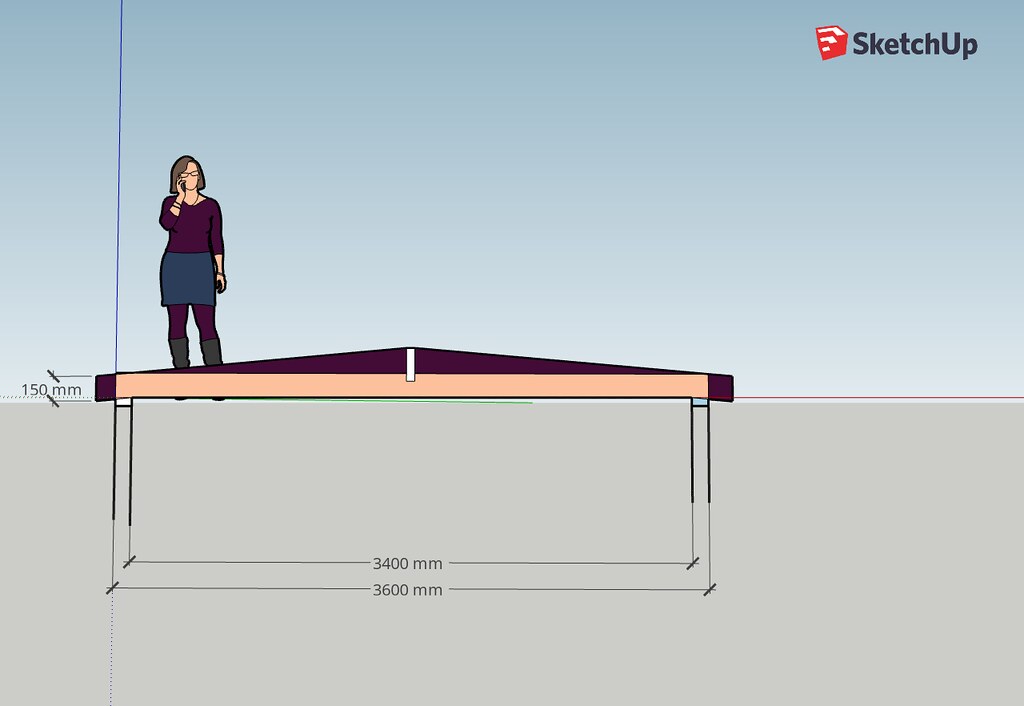

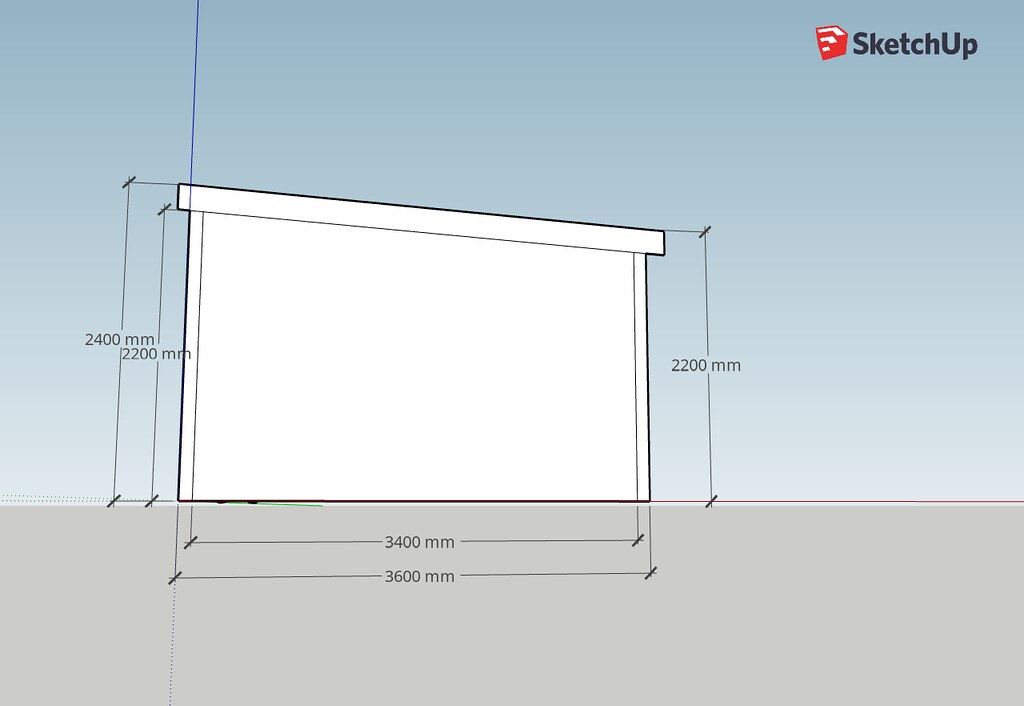

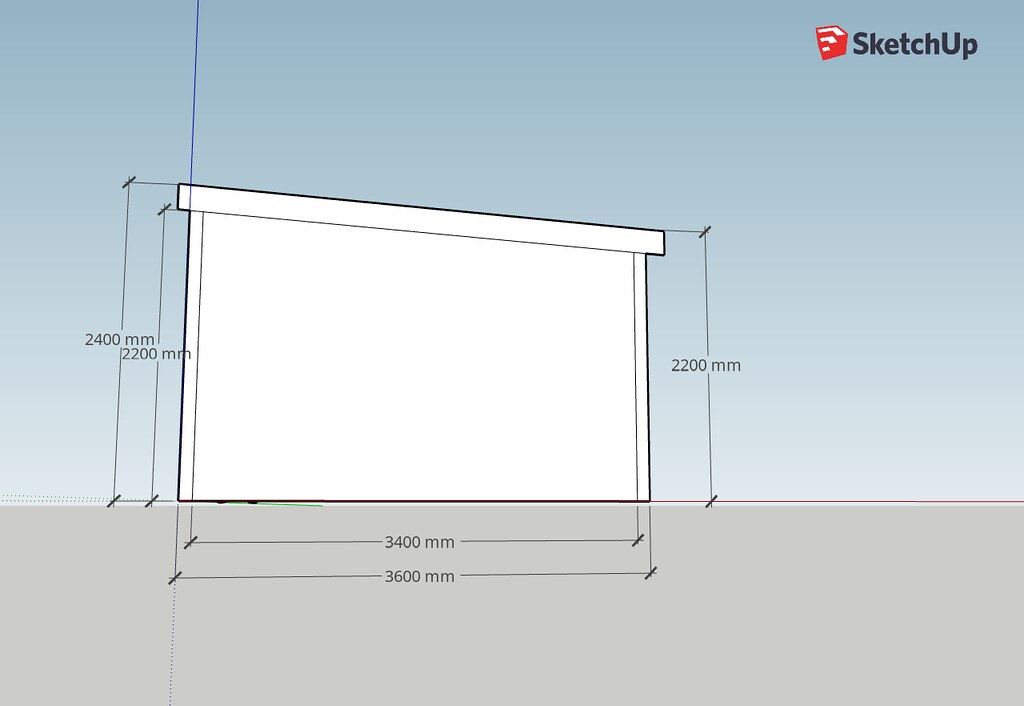

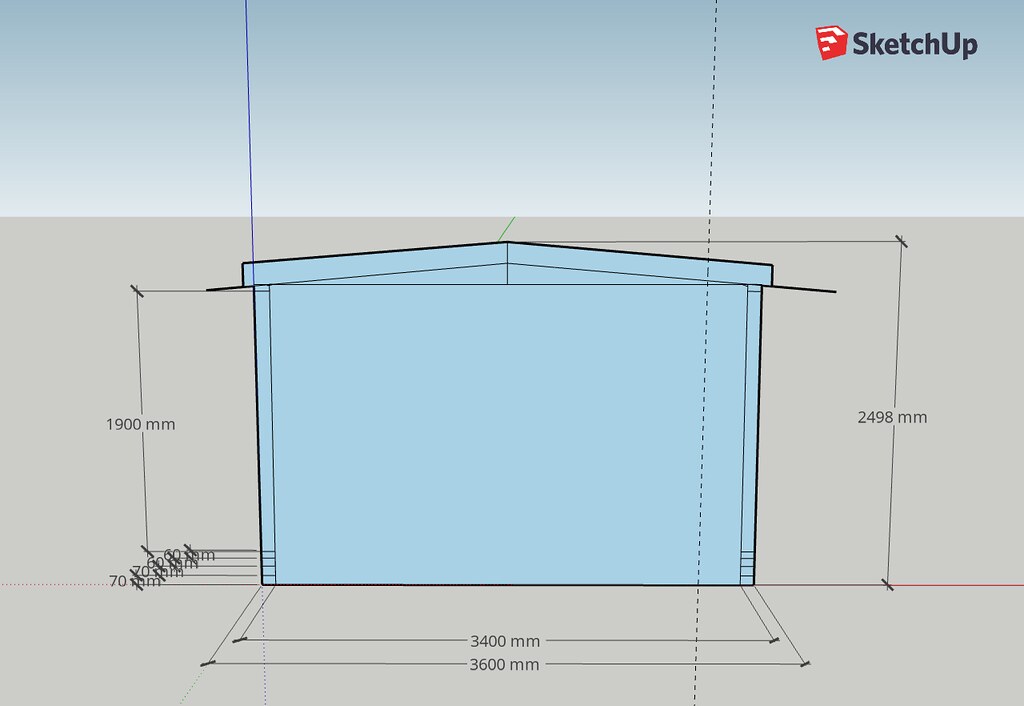

Would like a pitched roof, tho it will be low to keep under the 2.5m total height, so im not sure on total internal heights yet, and may have to go flat roofed to get the extra internal height?

Only just really played with sketchup in the last few days, but a rough guide to the two roof types,

Next stage it brick work, once I source a decent second hand UPVC door for the side for day to day access. Plan on making two large 1200mm wide doors the front, for potential vehical access if the need arises

Cost so far,

8, 3.6m 2x6 and 1, 4,8m 2x4, £88

12tons mot type 1 £336

large bag of sand £44

DP plast sheet roll £30

4, 3.6 x 2 sheets of rebar £84

rebar chairs £30

3.5M3 of pumped concrete £999.60

Only came across one root from the willow, thats been removed, the root that is, not the tree.

Was never going to be done quick, then covid strikes and due to spending a lot of time in the garden my 4 and 6 year old, kept playing in the hardcore out of bordem, so got 12t of mot type one, used 9ish and made the area safer to them, roll on not spending anything on drink and eating out, in went some sand , dpc, rebar and 3.5M3 of pumped in concrete.

So now i have this 3.6 x 7m x 150mm base, below 30M2 but well within 1m of the boundrys, so is getting the suitable fireproofing, cladding in hardie or cedral board.

Would like a pitched roof, tho it will be low to keep under the 2.5m total height, so im not sure on total internal heights yet, and may have to go flat roofed to get the extra internal height?

Only just really played with sketchup in the last few days, but a rough guide to the two roof types,

Next stage it brick work, once I source a decent second hand UPVC door for the side for day to day access. Plan on making two large 1200mm wide doors the front, for potential vehical access if the need arises

Cost so far,

8, 3.6m 2x6 and 1, 4,8m 2x4, £88

12tons mot type 1 £336

large bag of sand £44

DP plast sheet roll £30

4, 3.6 x 2 sheets of rebar £84

rebar chairs £30

3.5M3 of pumped concrete £999.60