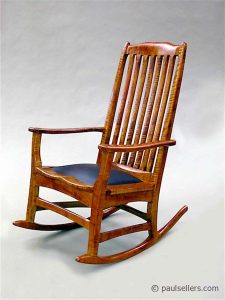

David Charlesworth seems to have gone very quiet, I would like to know what he thinks of Paul Sellers method of sharpening, I`ve been a fan of David`s method, not only for sharpening planes but also in fine tuning them, its methodical and accurately repeatable, Paul Sellers on the other hand, he seems a bit manic in almost everything he does, I recently watched a Youtube video of him making a workbench, the flattening of the top was almost laughable, I wonder how flat that top really was, I don`t think his work is what you would call fine furniture making, please feel free to prove me wrong.