stevebuk

Established Member

hi all

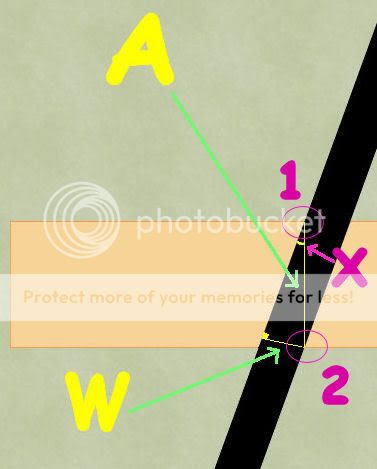

i have been asked to write a block of wood containing the words ' Wayne fixed it for us' but the letters must stand proud of the back they have been cut from.

I have managed to do this before but cant remember the angle of cutting needed.

Also would i have to cut the letters individually or can they be joined up?

i have been asked to write a block of wood containing the words ' Wayne fixed it for us' but the letters must stand proud of the back they have been cut from.

I have managed to do this before but cant remember the angle of cutting needed.

Also would i have to cut the letters individually or can they be joined up?