Half term is over (sort of) and it's back to work, or is that play??

Having not completely "clocked" back in at the evil overlords, I do have a little spare time for some fun. So fun is what I had and an update for the faithful followers has been compiled

It warms my heart to see you amused yourselves whilst I was gone :lol:

So spending a week fueled on Ouzo, sunshine and lamb I spent many a happy moment deciding where we need to go next with this project.

I noted from the nut modifications I was going to need some kind of guides. We don't want the travelling nut/clampy bit to wibble wobble about, it'll bind up some where on it's journey and that friends can not be allowed to happen =;

So from afar I ordered a bit of brass from the bay. 10 mm square and it was waiting for me when we got home.

The idea was to fix these brass guides at about the nuts mid point. So that's what I did. Some drilling and tapping and here's what we have.

The nut now has some restraint and with a little filing and a little sanding it's done.

Plans for the "dog" hole were made. I mentioned earlier I have some inch diameter brass bar and I decided this was going to be the preferred choice.

A hole was marked out and drilled. I went with 14mm, so if I turn down the end of my brass to about half inch I have a little slack. No sense in making things so tight there's a struggle to use it. The filing flat exposed a little porosity in the weld, must try harder next time, begger it! It'll do :lol:

Next thing needed is a top. I'll be going the same as the other end in having a overhang for drilling through and eventually fixing down.

Some more of the ali plate was marked out then cut off. The thin cut discs work brilliantly on aluminium, not as fast cutting as they do on steel but they make a decent clean cut.

So with that cut it's time to get a slot marked and cut.

With a trusty 25 mm holesaw we establish the ends of the slot. The pics tell it all.

The disc cutter was called on again to remove the waste.

*** and coffee time, which equals thinking time. Faced with a load of filing to finish up the slot I was less than impressed. Need to speed this up or at least avoid a filing session.

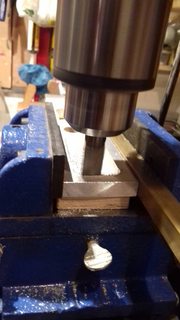

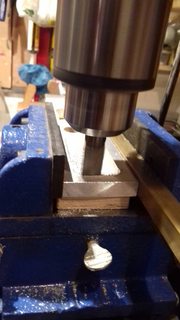

Remember the pillar mill from "dogs of wonderment"? Well it's back again \ /

/

The grey matter was bubbling away like a hot pan of peas.

Yes I've got it!! (says I)

Move the x y vice from the morticer onto the drill. Lock the quill, insert end mill, go wild 8-[

Now I'm not claiming to be tubalcain/Mr Pete, but this didn't work half bad. Slowish going true, but we'll worth a try.

Well actually as a disclaimer I suggest you only try this if:-

1, You have no sense.

2, Good life insurance. God only knows how you'd explain it on the paperwork, but why worry you won't be the one filling in said paperwork :lol:

:lol:

I wouldn't put a lot of stock in it being uber accurate and maybe the surface finish isn't the greatest, but I completed what I set out to do.

Filings and swarf everywhere, but hey how that's not a problem. Clean room this ain't.

So after a little squaring up with a file we have this. Not bad, I'm happy.

So the next bit is to drill and tap some more to fix this down properly and see about making the movable/clamping dog.

Bob is it getting any clearer now? I don't want anyone getting too far behind, the rest of the class only take the pith :lol:

As always, much love and thank you all for the continued interest.

Back soon.

Having not completely "clocked" back in at the evil overlords, I do have a little spare time for some fun. So fun is what I had and an update for the faithful followers has been compiled

It warms my heart to see you amused yourselves whilst I was gone :lol:

So spending a week fueled on Ouzo, sunshine and lamb I spent many a happy moment deciding where we need to go next with this project.

I noted from the nut modifications I was going to need some kind of guides. We don't want the travelling nut/clampy bit to wibble wobble about, it'll bind up some where on it's journey and that friends can not be allowed to happen =;

So from afar I ordered a bit of brass from the bay. 10 mm square and it was waiting for me when we got home.

The idea was to fix these brass guides at about the nuts mid point. So that's what I did. Some drilling and tapping and here's what we have.

The nut now has some restraint and with a little filing and a little sanding it's done.

Plans for the "dog" hole were made. I mentioned earlier I have some inch diameter brass bar and I decided this was going to be the preferred choice.

A hole was marked out and drilled. I went with 14mm, so if I turn down the end of my brass to about half inch I have a little slack. No sense in making things so tight there's a struggle to use it. The filing flat exposed a little porosity in the weld, must try harder next time, begger it! It'll do :lol:

Next thing needed is a top. I'll be going the same as the other end in having a overhang for drilling through and eventually fixing down.

Some more of the ali plate was marked out then cut off. The thin cut discs work brilliantly on aluminium, not as fast cutting as they do on steel but they make a decent clean cut.

So with that cut it's time to get a slot marked and cut.

With a trusty 25 mm holesaw we establish the ends of the slot. The pics tell it all.

The disc cutter was called on again to remove the waste.

*** and coffee time, which equals thinking time. Faced with a load of filing to finish up the slot I was less than impressed. Need to speed this up or at least avoid a filing session.

Remember the pillar mill from "dogs of wonderment"? Well it's back again \

The grey matter was bubbling away like a hot pan of peas.

Yes I've got it!! (says I)

Move the x y vice from the morticer onto the drill. Lock the quill, insert end mill, go wild 8-[

Now I'm not claiming to be tubalcain/Mr Pete, but this didn't work half bad. Slowish going true, but we'll worth a try.

Well actually as a disclaimer I suggest you only try this if:-

1, You have no sense.

2, Good life insurance. God only knows how you'd explain it on the paperwork, but why worry you won't be the one filling in said paperwork

I wouldn't put a lot of stock in it being uber accurate and maybe the surface finish isn't the greatest, but I completed what I set out to do.

Filings and swarf everywhere, but hey how that's not a problem. Clean room this ain't.

So after a little squaring up with a file we have this. Not bad, I'm happy.

So the next bit is to drill and tap some more to fix this down properly and see about making the movable/clamping dog.

Bob is it getting any clearer now? I don't want anyone getting too far behind, the rest of the class only take the pith :lol:

As always, much love and thank you all for the continued interest.

Back soon.