Hi

I have this ancient Faircut Senior set up in the garage but the bed is worn, It's very difficult to parallel turn on as when the gib strips are adjusted at the live end, The carriage won't back off (Wear is at the headstock end), If I adjust the gib strips at the dead end then there's chatter at the live end, It really needs stripping and trueing up but that would probably cost double the worth of the machine!

I traded a woodworking lathe for this Granville Senior (And tooling), This one came from a school that closed down, The metalwork tutor was allowed to take a machine, He chose this one as it was the best that was there..

I also dropped on a Myford 7 in fabulous condition which is nice but the bore through the spindle is smaller than the Granville, I was going to use it to thread the muzzles of air rifles in 1/2" UNF for sound moderators but I think most would be to large on the dia to fit through the bore!, The Granville would take most barrels

Both the Granville and Myford are 1950's machines with absolutely no wear yet the old Faircut is still setup as one of my sheds collapsed so all the stuff went in to the garage, I've since erected a larger shed- I filled the shed yet the garage is still full!

I shall have to get stuck in to clearing the garage sometime (Next summer!) and get one of the better machines set up!

By the way, I ended up kinda collecting lathes without realising it!

Here's a couple more..

This one is a round bed Wade hobby machine..

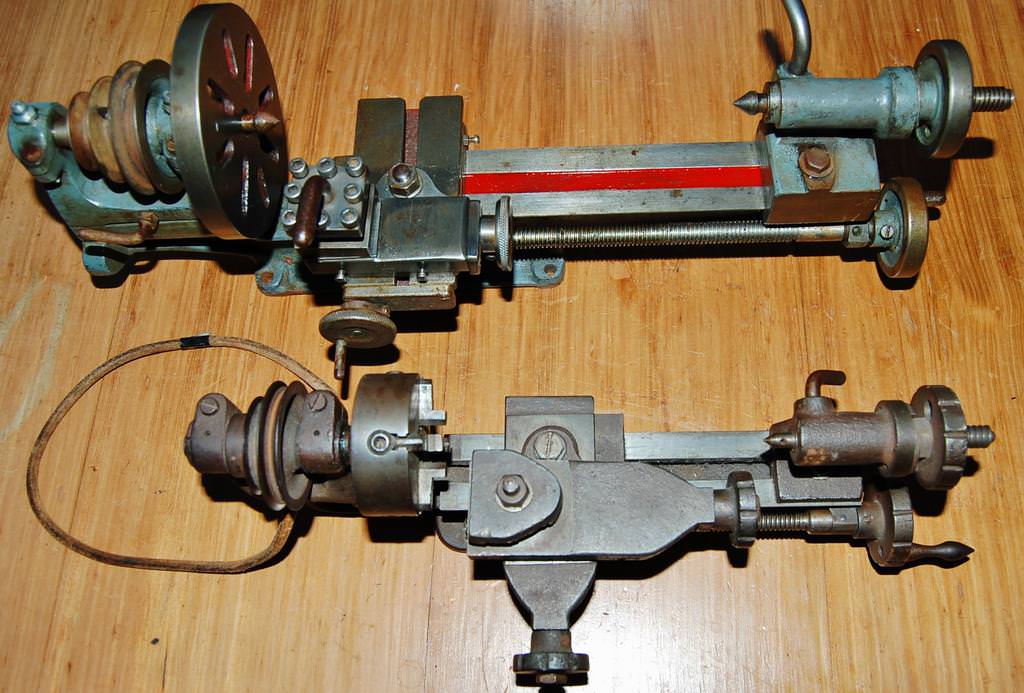

A couple of little ones!

Top is Flexispeed 7

Bottom is Adept.

This Unimat ML was the last one I bought, Never got around to setting it up though and probably never will!

John..