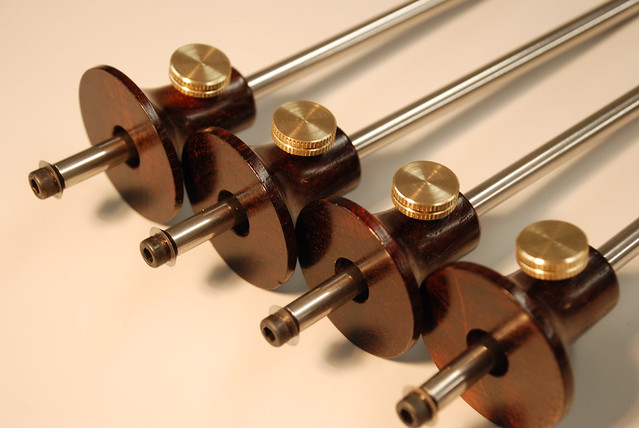

Sorry for the delay, but the gauge has been in regular use. Jim did some tuning of the blade as I found the original too biting. More of that in a moment. It has been put alongside a Marples Trial One, and a vintage ebony/brass mortice gauge:

A few notes:

- I asked for a shorter stem (compared to the No1 version) - this is 150mm and balances nicely, with ample capacity for normal use. This is up to the individual but I use these in the range say 5mm to 35mm, hardly ever more. I would use this with confidence at say 80mm, but I hardly ever would.

- it is quite heavy compared to a wooden one. Total is 400g, with stem 220, head 180. But I actually like the weight.

- the head is 61mm dia, No1 was about 51mm. I am very happy with the size but suggest optimum my be around 55mm.

- I chose the lock-screw, based on an old Spiers I think and similar to one Jim made for an infill he has. Knurling is probably optional but I like how this looks and it has ample grip. The vintage by the way, is all screw adjustments - a nice tool but I could not live with it for that reason.

- under the screw is a sacrificial soft metal insert to prevent the brass stem marking. Jim gave me 3 spares but I am certain the one that's in will last forever.

- The wedge locks very securely, and is easy to tap out. Normally the blade would stay in a long time, but as I was messing with blade profiles it's been in and out a lot.

- The wedge serves as a rest for a left-hand finger to orientate the blade to the work - I often hold these with both hands, using left to draw the gauge fence into the stock.

The blade profile settled on is fairly standard I suspect - a rounded point, bevelled both sides. Tried a bevel one side only - failure on the tracking front. Too pointy causes it to bite.

One benefit of the rounded stem is the ease of seeing the blade at work (single left-handed due to a camera in right hand).:

In summary, I think it is a beautiful execution of a classic marking tool. It's very largely traditional, and essentially a simple tool. The difference is in the precision and the quality of materials, making it a delight to own and use.