devonwoody

Established Member

Wednesday last posting and no work done, well the weather has been off hasn't it.

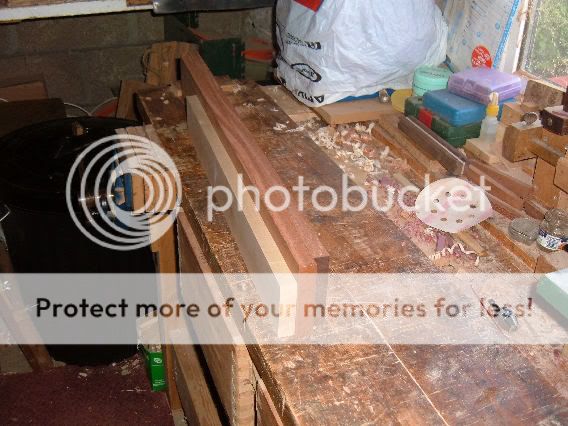

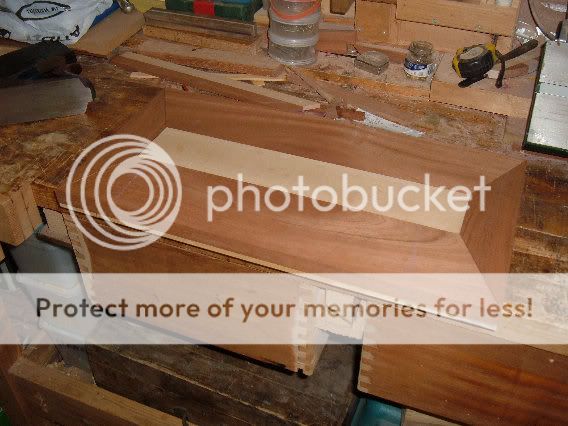

put a nice looking veneer on a 7mm thick piece of sycamore, not veneering the underside because with luck it wont cup. The third layer is going to be the drawer carcass.

Glued on with Titebond 3 and held in place with masking tape and clamped between boards in the bench vice.

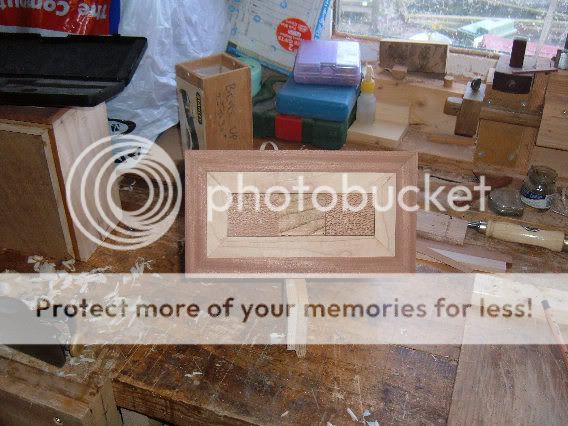

Positioned here 40 x40mm squares.

Handles next to be fitted, black walnut and maple stripe.

put a nice looking veneer on a 7mm thick piece of sycamore, not veneering the underside because with luck it wont cup. The third layer is going to be the drawer carcass.

Glued on with Titebond 3 and held in place with masking tape and clamped between boards in the bench vice.

Positioned here 40 x40mm squares.

Handles next to be fitted, black walnut and maple stripe.