devonwoody

Established Member

Another two days of little progress (owing to weather, 60mph gales)

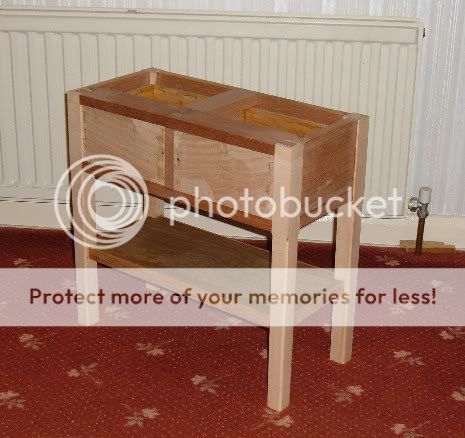

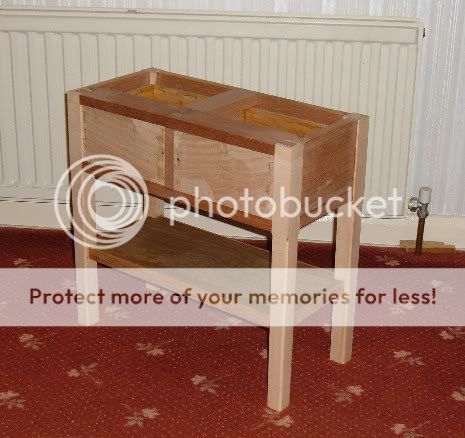

Tidied up the side panels and fitted the drawer carcasses.

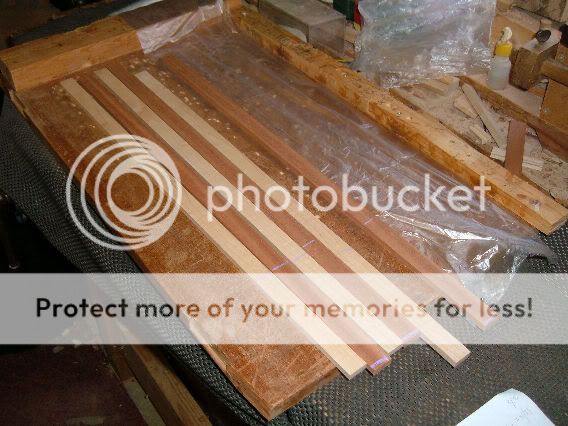

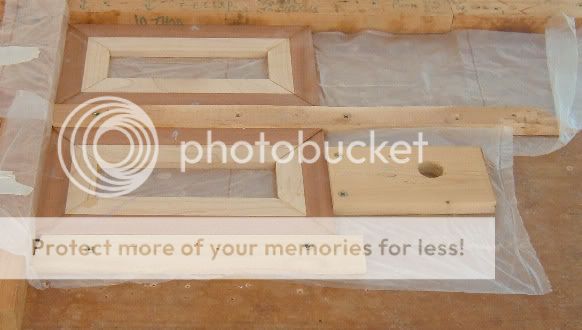

Put the table top timbers away under the bed the other day to keep all the wood happy, and got a design idea for drawer fronts as soon as the weather calms down.

Tidied up the side panels and fitted the drawer carcasses.

Put the table top timbers away under the bed the other day to keep all the wood happy, and got a design idea for drawer fronts as soon as the weather calms down.