devonwoody

Established Member

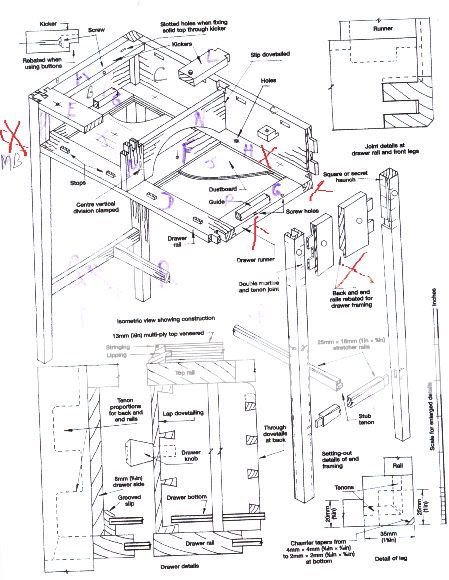

Dave R of USA is drawing up the final making up diagrams of a stand to store laptop and also called a console stand.

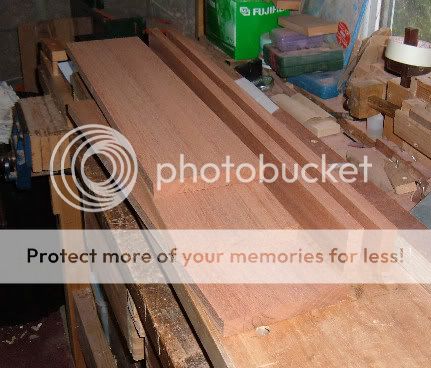

Timber obtained today. some 75mm thick Canadian Maple which has a moisture content of 11 percent, so should be ready for immediate use. I think it is also suitable to be quarter cut to make boards for the top.

I would still like to contrast the maple with either Sapele or the black walnut also obtained has a reject piece at the same time as Maple.

What advice can you give re contrast edge for the top?

Timber obtained today. some 75mm thick Canadian Maple which has a moisture content of 11 percent, so should be ready for immediate use. I think it is also suitable to be quarter cut to make boards for the top.

I would still like to contrast the maple with either Sapele or the black walnut also obtained has a reject piece at the same time as Maple.

What advice can you give re contrast edge for the top?