I have mine set the same and it is perfect for 95% of the time as the 0.5mm allows the material to just float along. It is only a problem when cutting veneered panels etc when the 0.5mm can be a problem for spelching (I do not have a scoring unit) but I just use a piece of 12mm pdf as a zero clearance sub table. It can also be a problem machining wide boards on the spindle.I use a Felder saw with a sliding table, but actually these same general principles apply to all sliding tables.

If you're chiefly using the sliding table to cut sheet goods, then you're best off with the sliding table slightly higher than the main table. Felder/Hammer recognise this and therefore the sliding tables are fully adjustable. Most workshops I know seem to set this gap at about 0.5mm, but I've seen gaps up to 3mm. This reason is that this makes it easier to transport "floppy" sheet goods like MDF across the saw. If you've ever ganged up a stack of say 20 hardboard sheets for cutting wardrobe backs then trust me, you'll really appreciate a gap that's towards the larger end of the spectrum! I understand some joiners who are using resinous softwoods, particularly if they're not always as well kilned as they might be, also prefer a larger gap.

On the other hand, if you mainly use your saw for hardwood furniture then you'll probably go for a smaller gap or even no gap at all (ie dead flush). However, note that the risks are asymmetric, in other words a tiny gap with a higher sliding table is no big deal, but the same tiny gap with the main table higher makes sawing difficult and is potentially dangerous. Furthermore, with very small gaps you're also into the zone of how flat are your tables? In other words you want a safety margin across the full travel of the slider and the full width of the table.

Consequently, even though I chiefly use kilned hardwoods, I have my sliding table 0.5mm higher than the fixed table and I'm a happy camper.

Hope that helps.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hammer K3 Slider - questions for owners

- Thread starter Prizen

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

custard

Established Member

It is only a problem when cutting veneered panels etc when the 0.5mm can be a problem for spelching (I do not have a scoring unit) but I just use a piece of 12mm pdf as a zero clearance sub table. It can also be a problem machining wide boards on the spindle.

You make some interesting points. It's a bit of a digression but I work a lot with veneered panels and even though I do have a scoring blade, for the very finest work I don't use it.

I used to always use a scoring blade for veneered work, but then I spent a couple of years at The Edward Barnsley workshops. They argue that setting a scoring blade for absolute accuracy is tricky, and it's all too easy to end up with an absolutely minuscule gap (I'm taking less than 0.1mm) not normally a problem, unless it's a very pale veneer, when after a few years household dust can get forced into the gap and leave a similarly miniscule dark line. Their argument is that you can't spot this level of discrepancy at the time, it only becomes apparent later on.

I fully concede that you have to be beyond obsessive to plan for any of this, but for what it's worth I've subsequently met several Guild Mark quality craftsmen and women, and they also tend not to use their scoring units.

So if not a scoring blades what to use? Well, it's a combination of an MDF sub-table as per your method, plus a top quality, freshly sharpened ATB saw blade. It's also one of those situations when you reap the benefit of a really good saw with flawless bearings and super heavy trunnions.

Yes the ATB is usually so sharp I need gloves on just to fit it.So if not a scoring blades what to use? Well, it's a combination of an MDF sub-table as per your method, plus a top quality, freshly sharpened ATB saw blade. It's also one of those situations when you reap the benefit of a really good saw with flawless bearings and super heavy trunnions.

Derek Cohen (Perth Oz)

Established Member

Is that the 1300mm sliding carriage? The sales rep says I should take the comfort package which has the 2000mm sliding carriage. A 2m sliding carriage is too big for my space. Did you have to start with the k3 winner in standard configuration and take everything else as an optional extra?

Hammer equipment is solid and reliable. I have the combo thicknesser/jointer and bandsaw as well the K3 Winner slider.

The K3 I have came with the 1250 wagon (it actually rips 1345mm), along with the Professional (upgraded) fence (the one on the round bar). This is a basic unit with an upgrade to the rip fence. No scoring unit, and I do not do dados on a table saw.

My target area is solid wood furniture. I do not work with MDF or chipboard. If you work with melamine coatings, then you need a scoring blade. Not relevant for me.

My space is limited to a double garage (and half of this is for machines, the other half for hand tools) ...

Older photos ...

The K3 has received a number of modifications/additions to improve it. One is the Wixey digital gauge ...

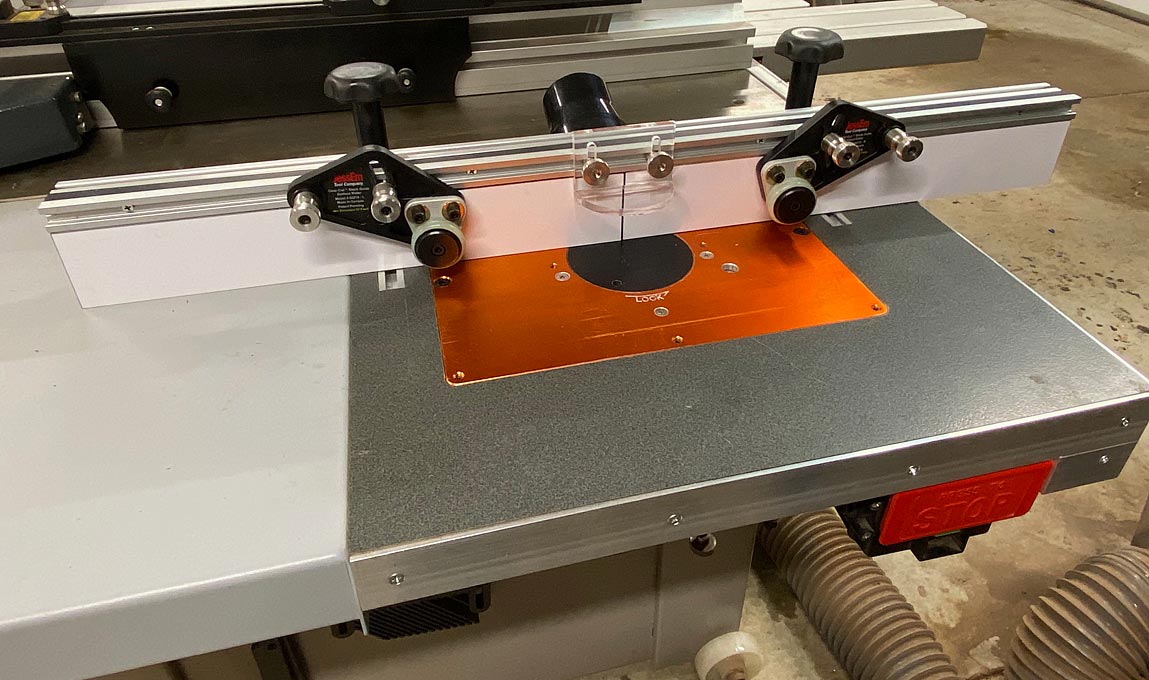

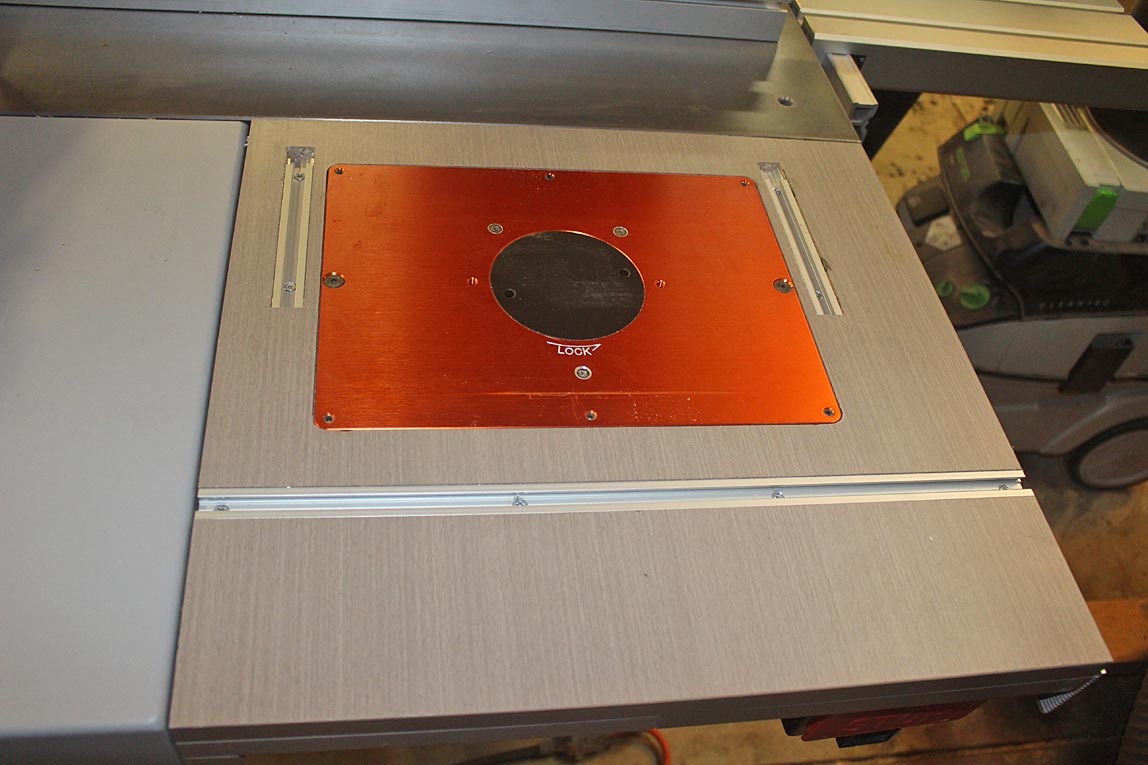

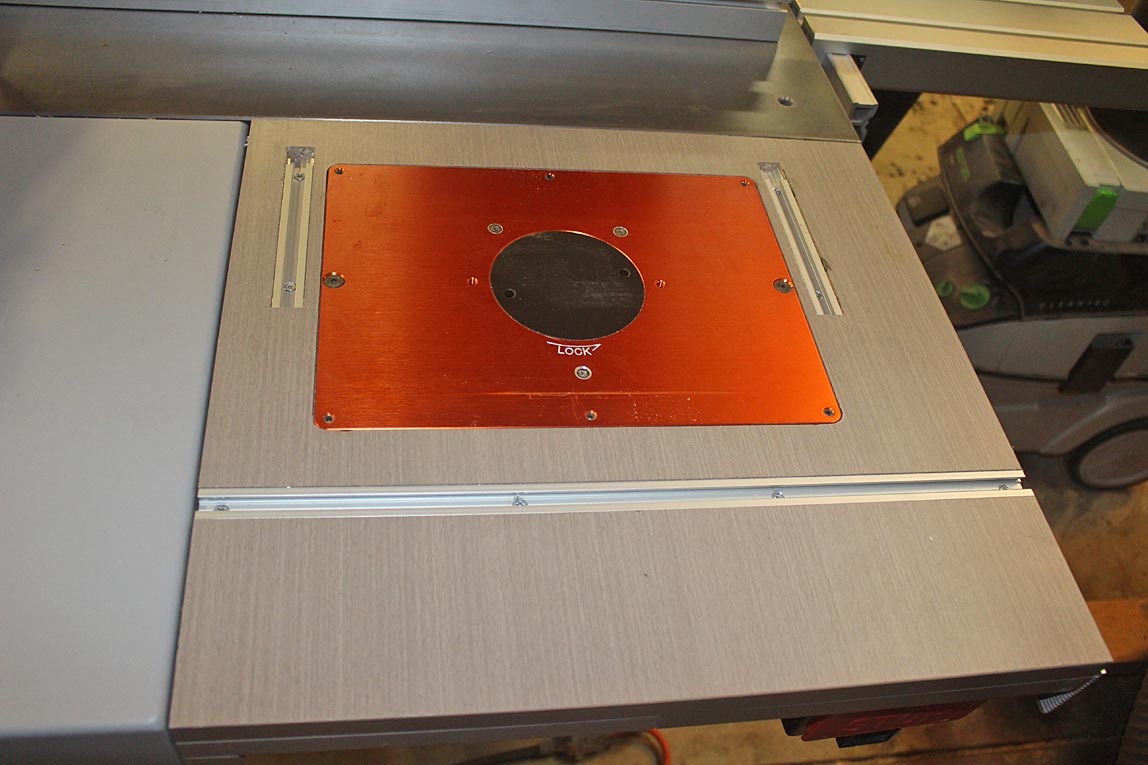

Another was the addition of a router table to the outfeed ...

Read up on Fritz & Frans jig - lots on YouTube. The wagon without the outrigger requires that it work in reverse. Consequently I designed a "reversed F&F jig" ...

Using the F&F makes you aware that a 800mm wagon is too short. Do not be tempted to get one. The 1250 works well (and there are ways to make it work longer - more on this another time).

To answer the original question, the wagon is set 0.5mm above the cast iron top. This is to reduce friction when crosscutting. It does not affect the angle of rips on the rip fence (in theory yes, but not in practice).

Regards from Perth

Derek

Thanks Derek, that is a really informative top quality post! I really like the idea of the router table in the right hand side of the machine. Would you mind sharing how you managed to add-on the router table? Really interested in this!

Derek Cohen (Perth Oz)

Established Member

Prizen, I only have pics of the previous table, but the method was the same.

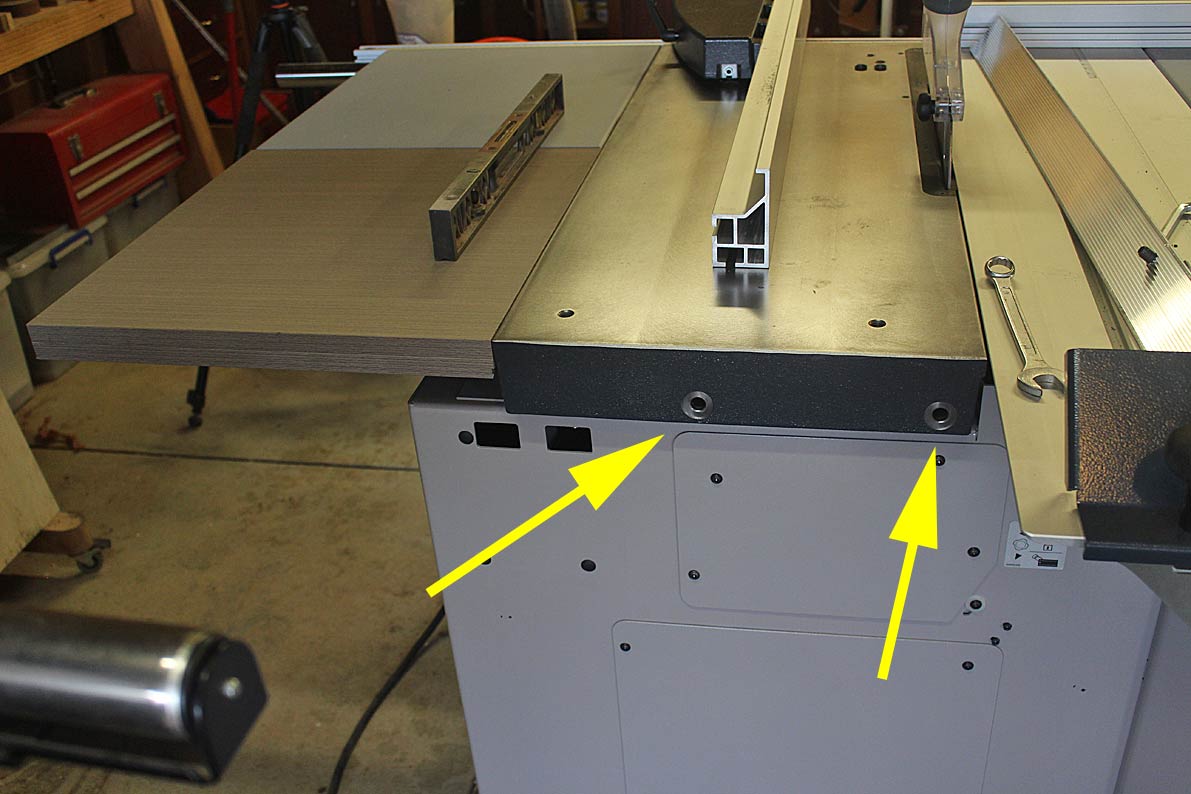

Here is the old table ...

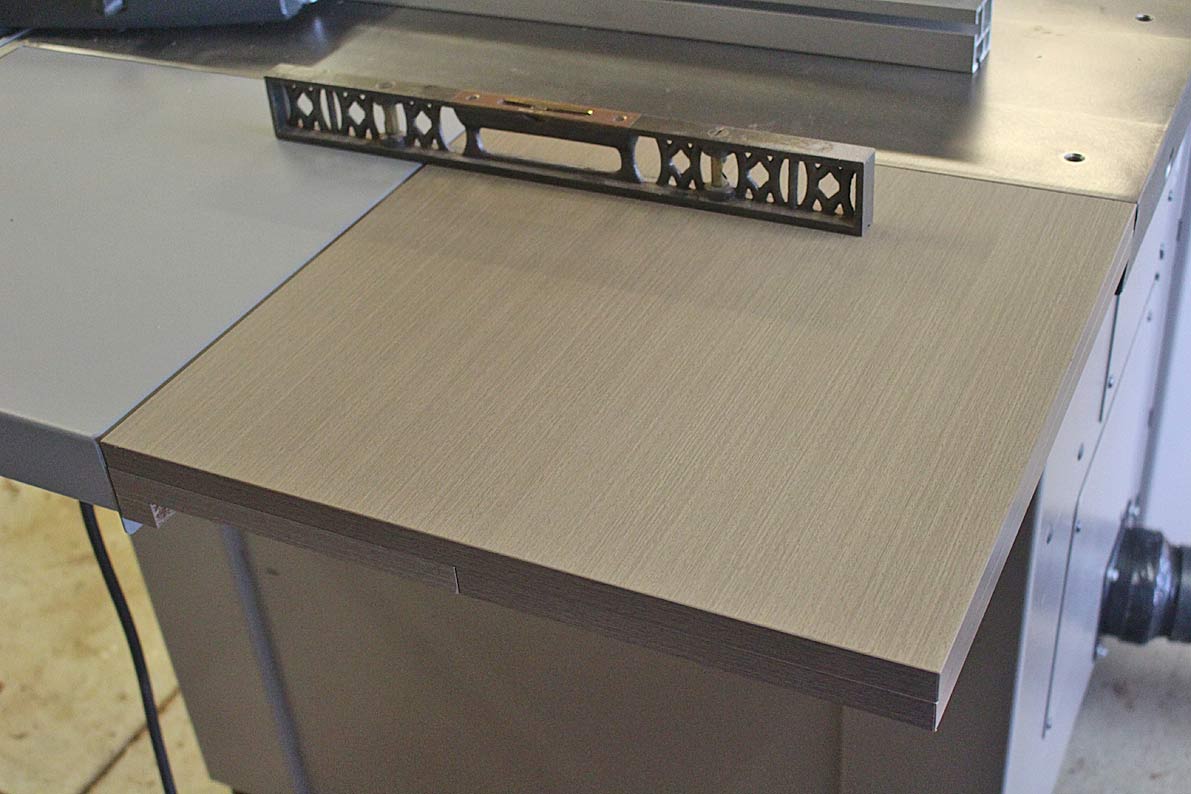

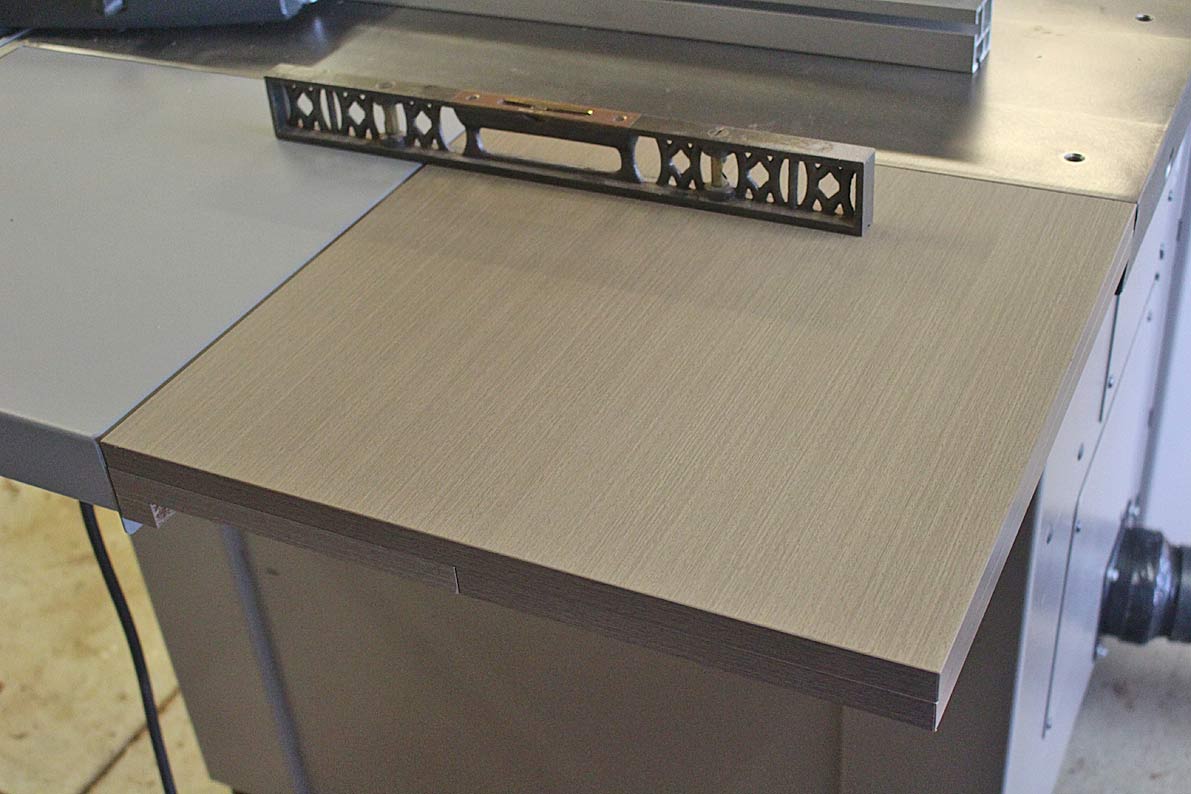

My K3 came with a half-panel ...

The top ...

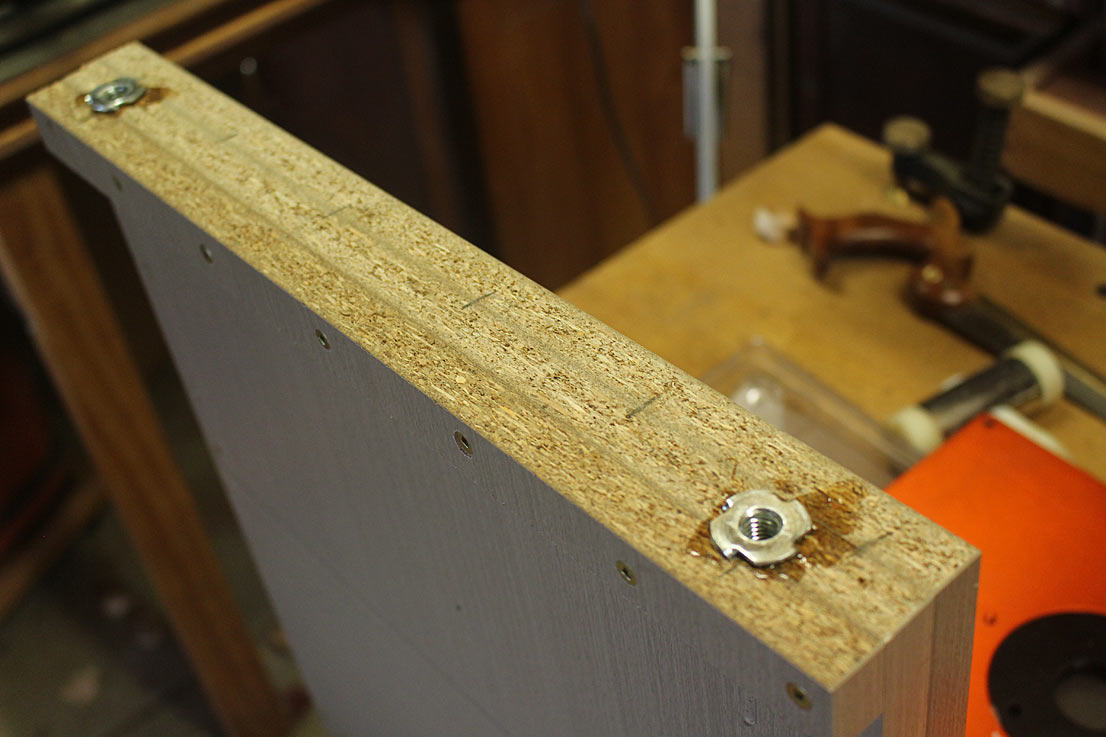

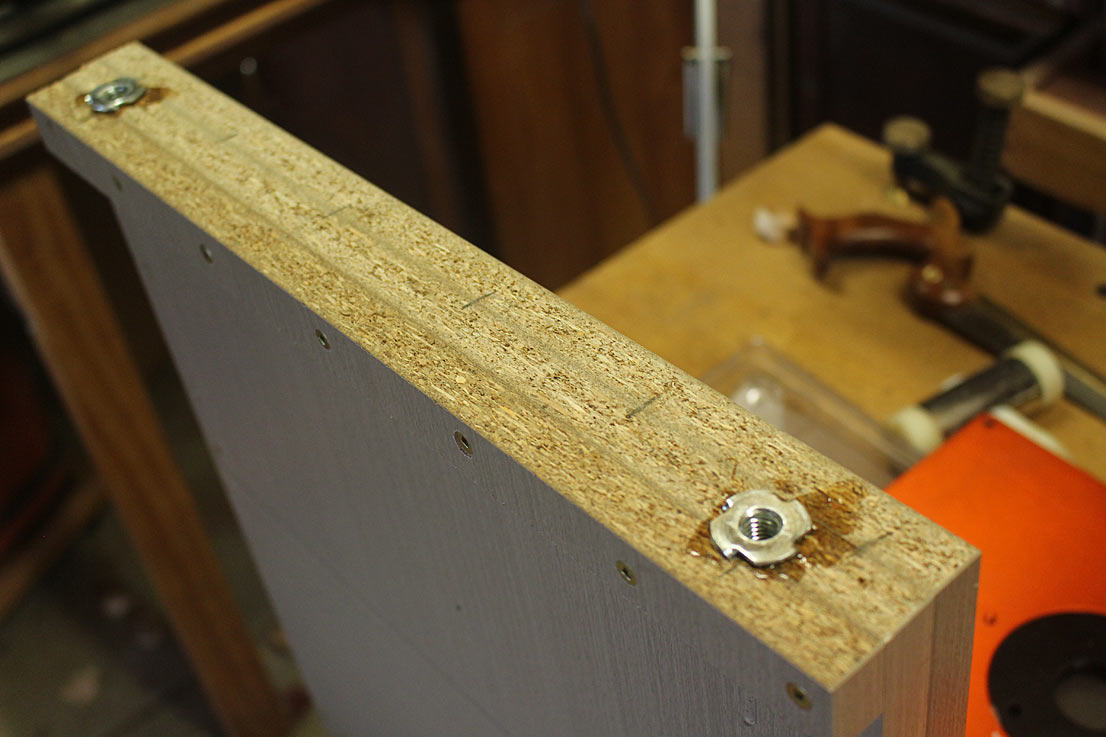

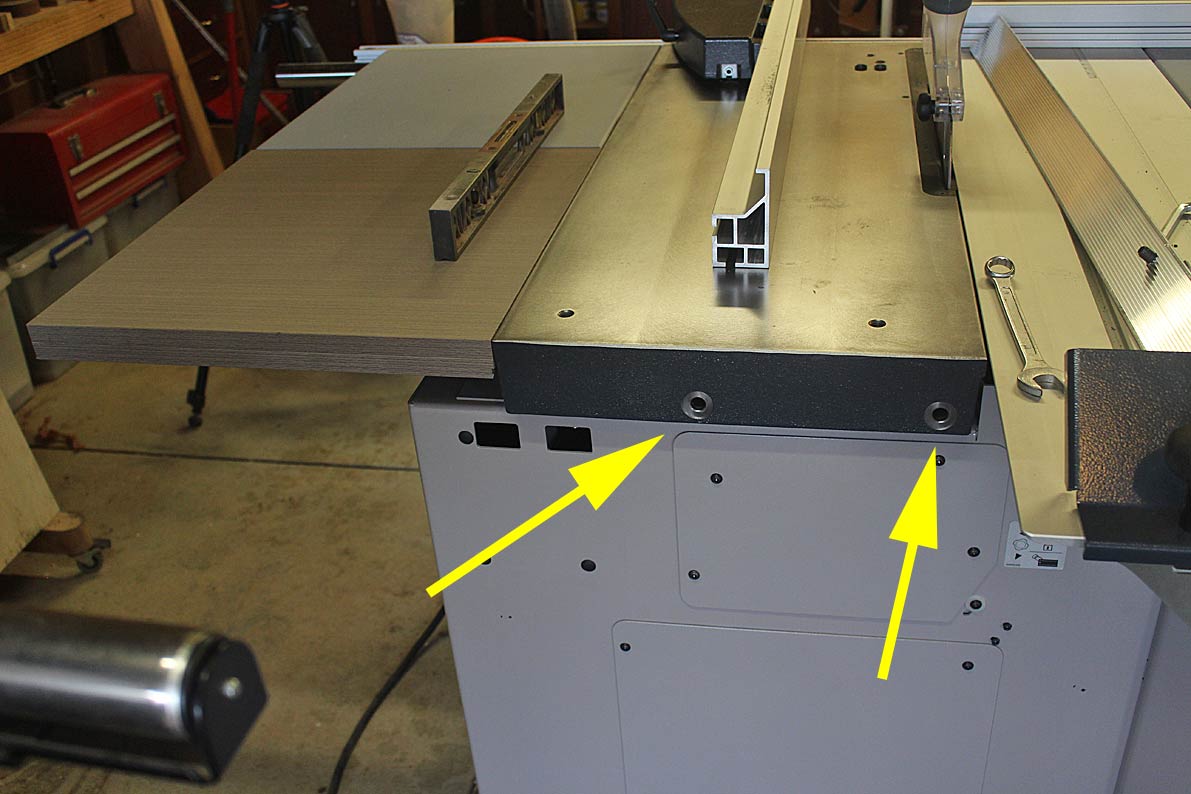

... is secured at one side by bolts into inserts (there are convenient holes in the saw case) ...

Facing the saw, add bolts as legs ...

And the far side I used existing bolt holes to support an aluminium section ...

Current:

There is a lot more to this build - indeed, some of it is still in process. But it is now at a functional level. Let me know if you want more.

Regards from Perth

Derek

Here is the old table ...

My K3 came with a half-panel ...

The top ...

... is secured at one side by bolts into inserts (there are convenient holes in the saw case) ...

Facing the saw, add bolts as legs ...

And the far side I used existing bolt holes to support an aluminium section ...

Current:

There is a lot more to this build - indeed, some of it is still in process. But it is now at a functional level. Let me know if you want more.

Regards from Perth

Derek

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£96.66

£102.61

O'SKOOL Mortise and Tenon Jig is Ideal for cabinets, Chairs, and Table Construction Using a Plunge Router

Amazon US

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

Derek, that is fantastic info, many thanks. I might pm you for details, but I am sure there will be an extended wait time. I am also strongly considering the Minimax SC2 from SCM. It will come down to price

Similar threads

- Replies

- 6

- Views

- 1K