Cheers for the positive comments guys...it is really my first venture into this area and I have learned a lot that I would change next time but what gets me is the beautiful way this plane cuts.

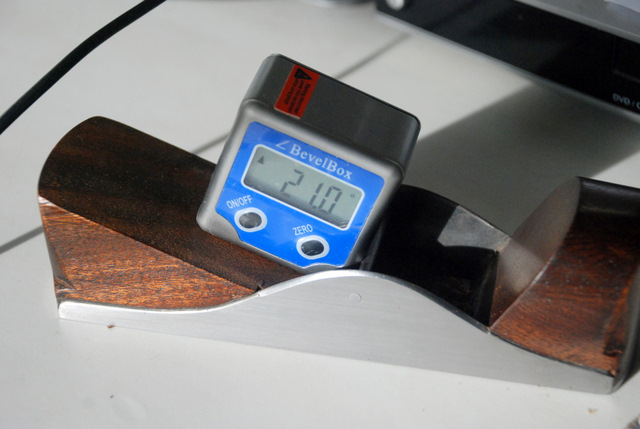

Derek...I was aiming at the same 20 degree bed as found in the 110....

....so not that far out really.

I intend to use a very thick flat blade in the final version but this little Isaac is doing an admirable job...I just put a secondary bevel in it at 25 degrees so I have a cutting angle of about 46 degrees.

I was reading the "Smoothing Burr" thread and thought that too might be a challenge especially since I just received a rather nice rough piece of burr elm in the post this morning....

This is how the other side was when I received it and before planing:

....and it had no problem cutting very fine shavings with virtually no tearout...

I am really pleased with the way it performs so far...I need to create a thick blade...get the cap and install and see how it changes.

One thing is for sure...even now..it is a plane I want to pick up and use every time as a matter of choice....

Now....to watch you HC with the smoother/jack and see if I need to make another.... :wink:

Jim

P.S. yes John....it is a RAM! 8)