excalibur 21 user":zypjk20s said:

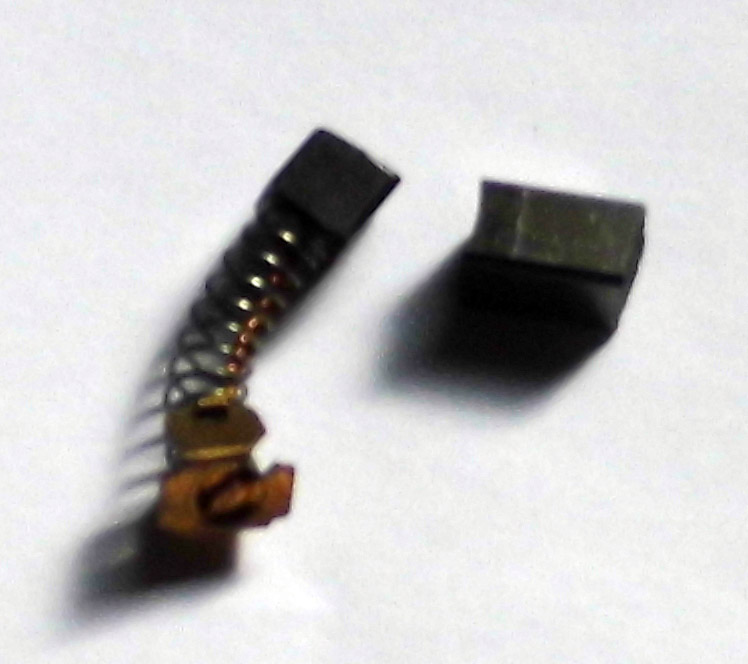

Thanks for the info scrimper, the glass fuse in the machine blew as this happens sometimes. I would just get a new fuse and everything is fine again for a few months but this time it wont work.. I have tried a new setup with new fuses,plugs and leads etc. I have a multimeter but am a bit worried about testing the switch with it so thought I would try new brushes first. The brushes I removed look fine, they had some black on them but that could be rubbed off. Cheers

If you have a multimeter you should have no problems with testing. with the saw unplugged just test the various circuits for continuity but bear in mind that for proper testing you often need to disconnect an item otherwise it's possible to get a parallel reading and send yourself on the wrong track, find the leads that go to the motor and disconnect one of them (to avoid a parallel reading) then check for continuity across the motor, if there is then you can rule out the motor being faulty. same with the switch etc.

so the guy suggested changing the motor brushes.

so the guy suggested changing the motor brushes.