You are confusing radius and diameter.

https://www.mathsisfun.com/geometry/circle.html

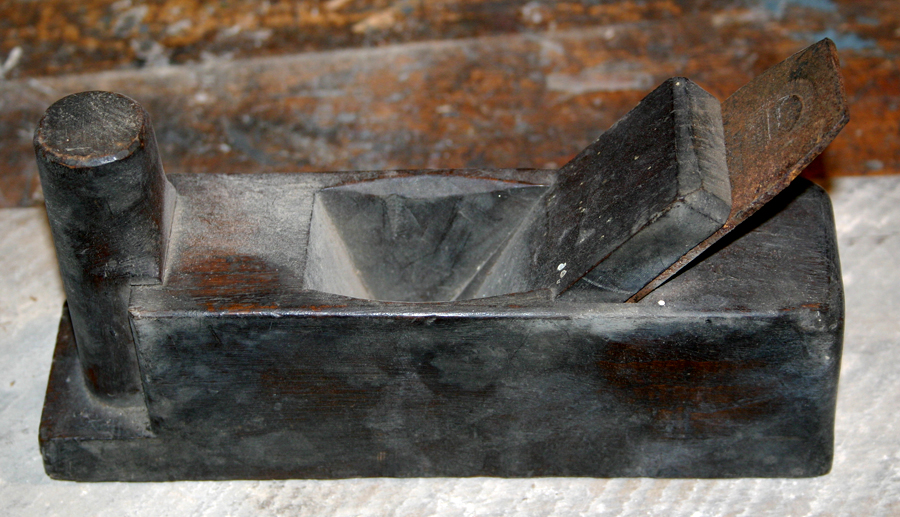

Worried (dementia setting in?) I just carefully measured my ECE blade (the one in the snap) and it has a

radius of about 30mm. slightly less than 1 1/4". I set a compass at 30mm radius, drew a circle and dropped the blade on for a close fit.

This would give a

diameter of less than 2 1/2" i.e. same radius would give a neat but very unusual complete semi circular camber in the end of a normal jack with 2 3/8" blade. (With a 30mm 'sagitta', to use bugbear's favourite word!)

This would work as a scrub but not be a very effective use of a plane - heavy and most of the blade un usable. Would it stay in situ under the cap iron?

Hence a jack or a smoother can't sensibly be adapted to emulate a scrub like the ECE, though they can of course be heavily cambered a little way in that direction.

The ECE is how it came, though it isn't as regular now as it was when new, I'm fairly slapdash with sharpening.

PS and of course the ECE removes wood much faster than you could possibly do with an adapted jack, but leaving a rough surface like an adze or gouge.

Which begs the question, how can this be, surely same amount of effort can only remove same amount of wood?

The answer is that the scrub shavings are thick, more like long chippings, like a ploughed field. A shallower cambered plane would have to slice through these shavings several times, with several times as much effort.

Or to put it another way - the finer the camber the more cuts you have to make to remove a given amount of wood. You could chop a tree down with a razor blade but it would take some time!