DBT85

Established Member

OK great, thanks. I'll get rod, I've cut enough of it so I know the trick with the nut.

I don't have direct access but we know people with just about every type of machine for farms you can imagine. At a cost of course!

Is this for lifting the ridge?

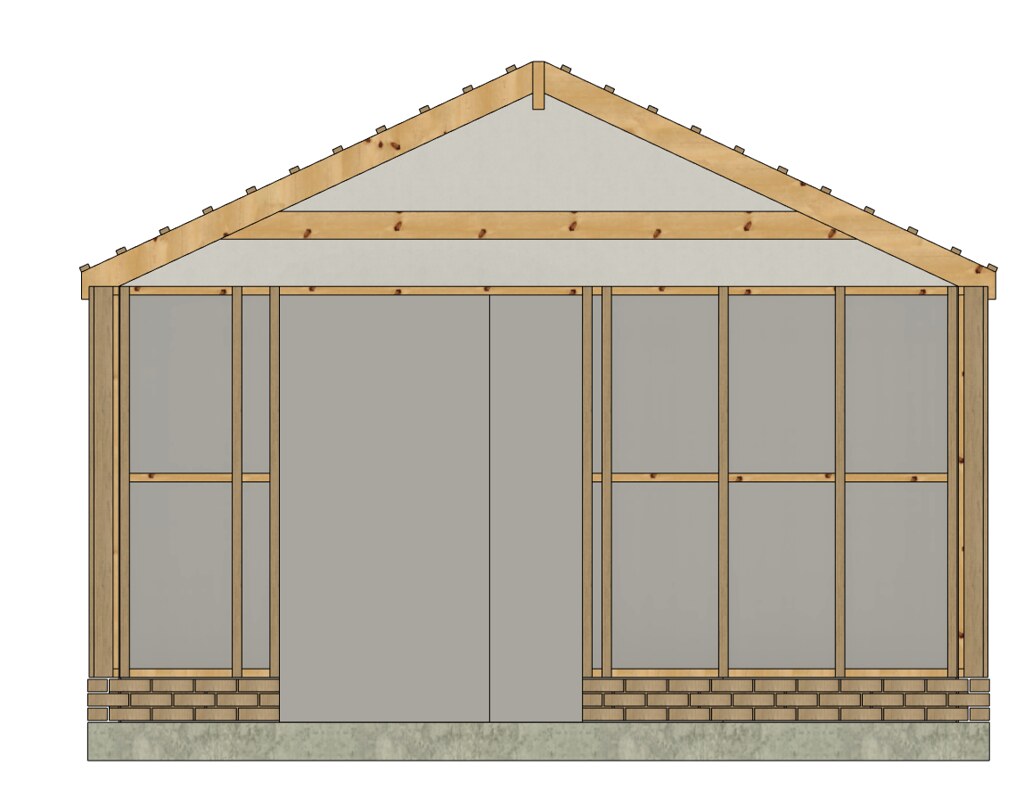

The off-the-top-of-my-head plan is to use the formwork timber to make something to hold the ridge up anyway until such time as the first 4 rafters are in.

That can have holes in it every couple of feet to take a rod. I would lift one end up high enough to get a rod in under it, and then do the other end. Then lift the first end up to the next hole. Etc. At one time I'd only be lifting half the weight and only say 500mm at a time. With assistance.

I don't have direct access but we know people with just about every type of machine for farms you can imagine. At a cost of course!

Is this for lifting the ridge?

The off-the-top-of-my-head plan is to use the formwork timber to make something to hold the ridge up anyway until such time as the first 4 rafters are in.

That can have holes in it every couple of feet to take a rod. I would lift one end up high enough to get a rod in under it, and then do the other end. Then lift the first end up to the next hole. Etc. At one time I'd only be lifting half the weight and only say 500mm at a time. With assistance.