swagman

Established Member

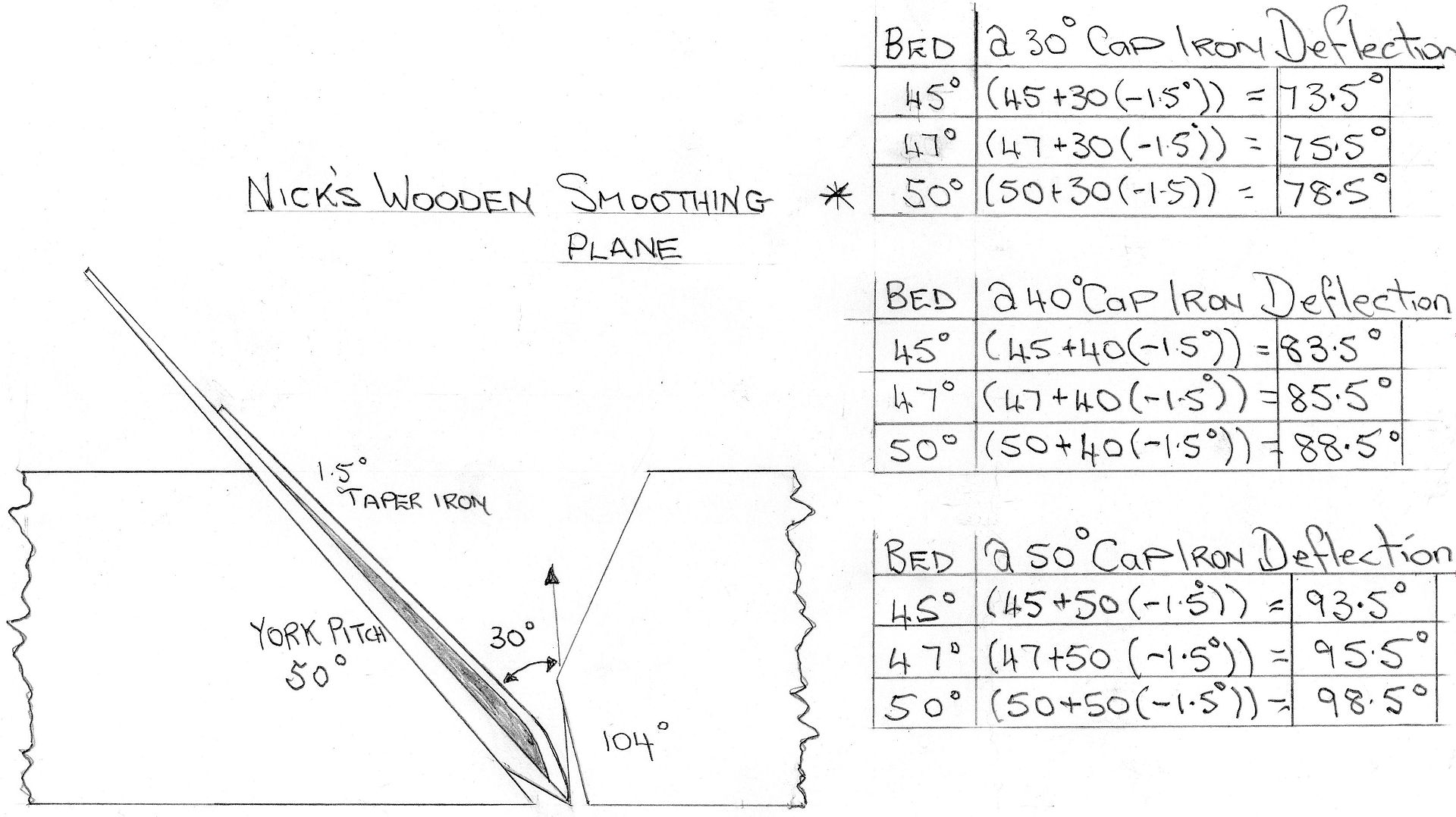

There has been a wide range of opinions on how close to set the Cap Iron in relation to the cutting edge of the blade. So much so that I am going to avoid further discussion on that topic, and focus instead on the defection angle that's required on front edge of the Cap Iron. The following study has nothing to do with a metal bodied bench plane, the likes of a Stanley or Record bench plane. imo, these type of planes exhibit such a low front wear face, that if you were to choose a defection angle in the upper range of 50 - 55* , it will have a little to no bearing on restricting the natural flow of shavings.

Moving onwards;

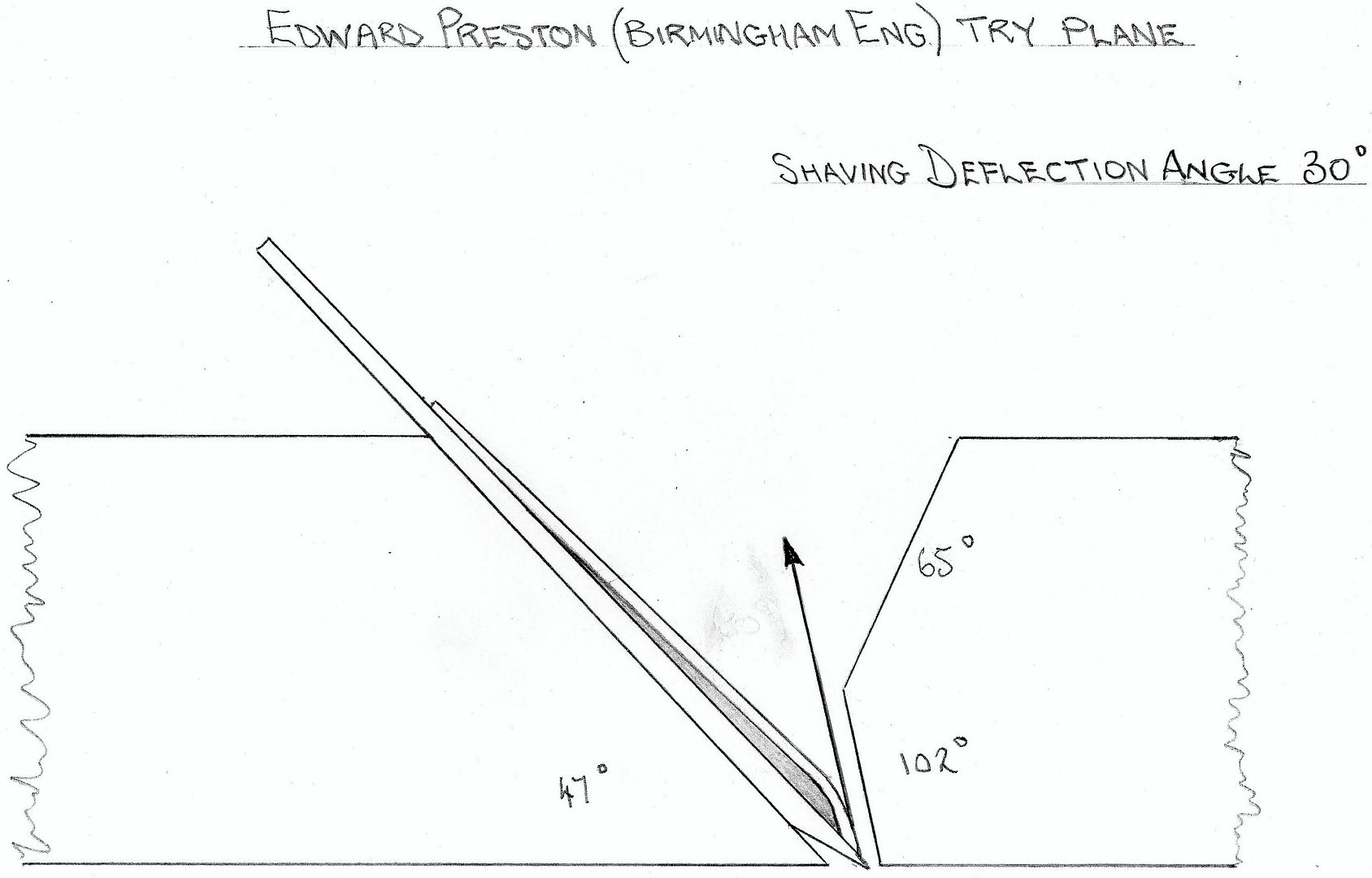

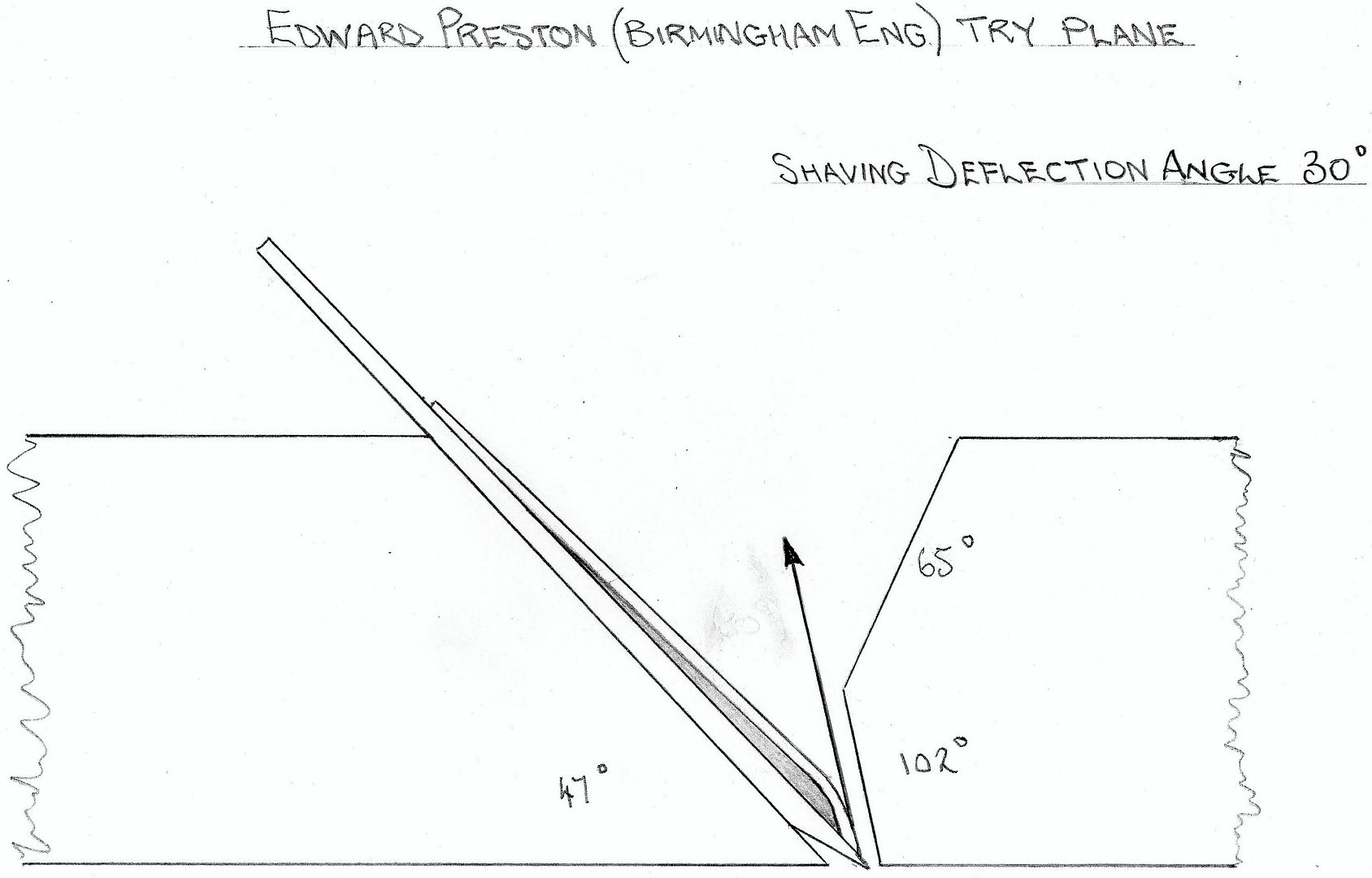

I have included 3 diagrams that replicate a 1/1 scale of the inner workings of the Edward Preston Try Plane that I recently posted photo's of.

The 1st drawing shows the current defection angle that was measured at 30* from the Try Planes front edge profile. The front edge of the Cap Iron shows no sign of a steeper secondary bevel being applied. Other than showing signs of being polished by its previous owners , the Cap Iron is in original condition as supplied by the planes maker.

Take special note that with a 30* shaving deflection drawn in, its parallel alignment to the wear face are near exact. Also note that at this angle of shaving deflection, the wear face poses no real obstruction to the shaving as its directed through and exits the throat of the plane.

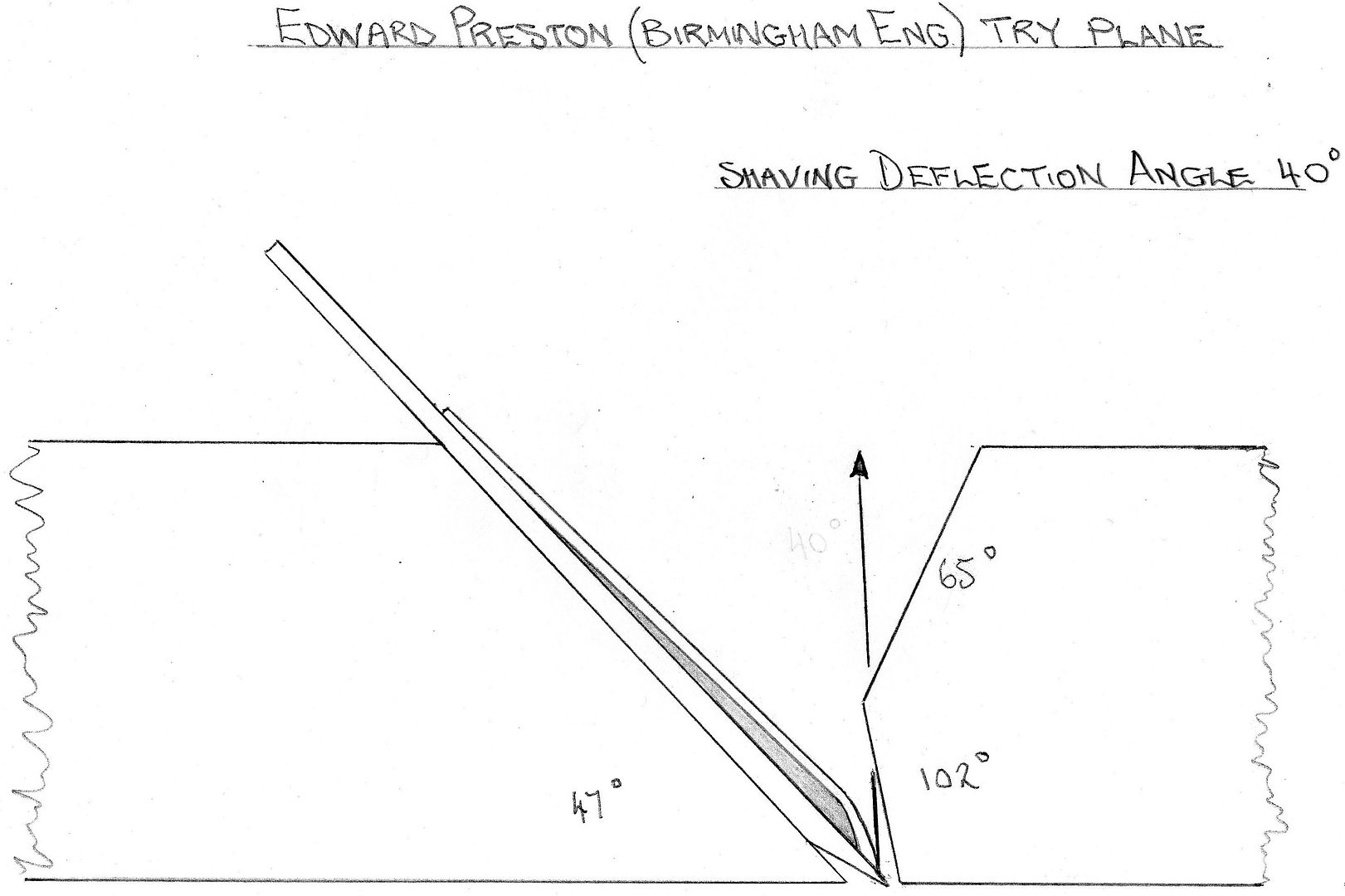

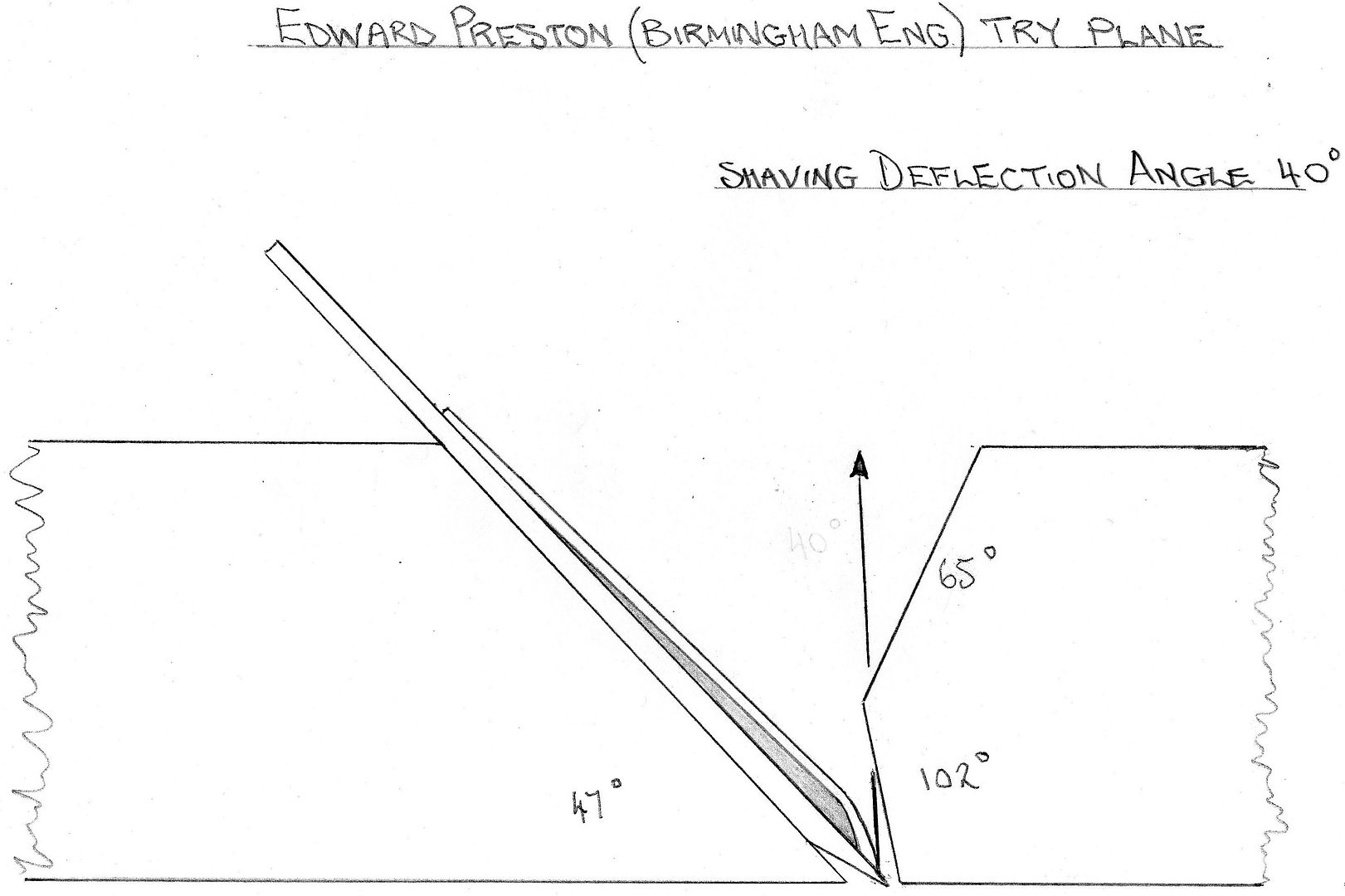

The next diagram shows the effect of increasing that shaving defection to 40*. Note how the wear face is starting to serve some role in redirecting the shaving.

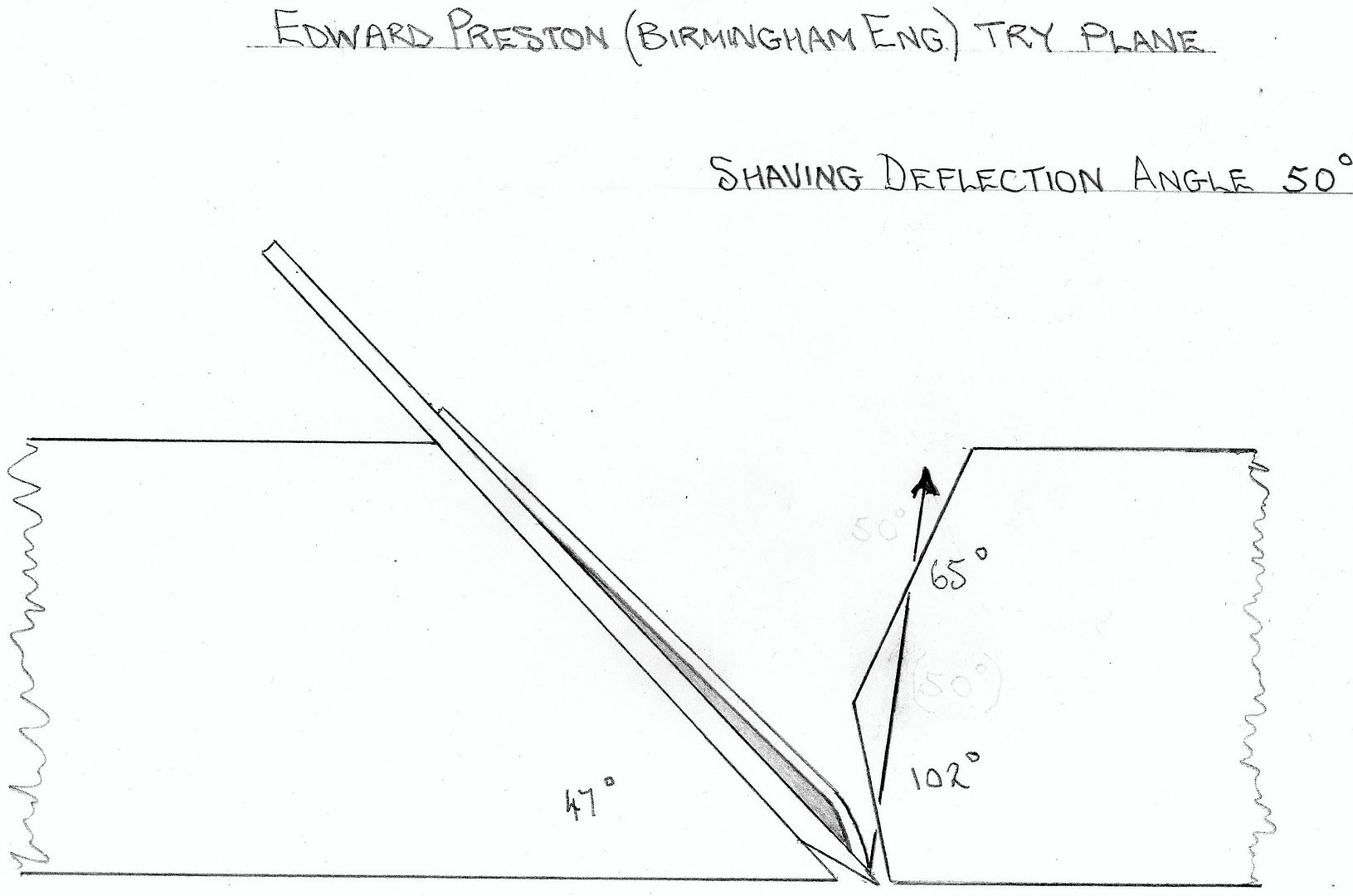

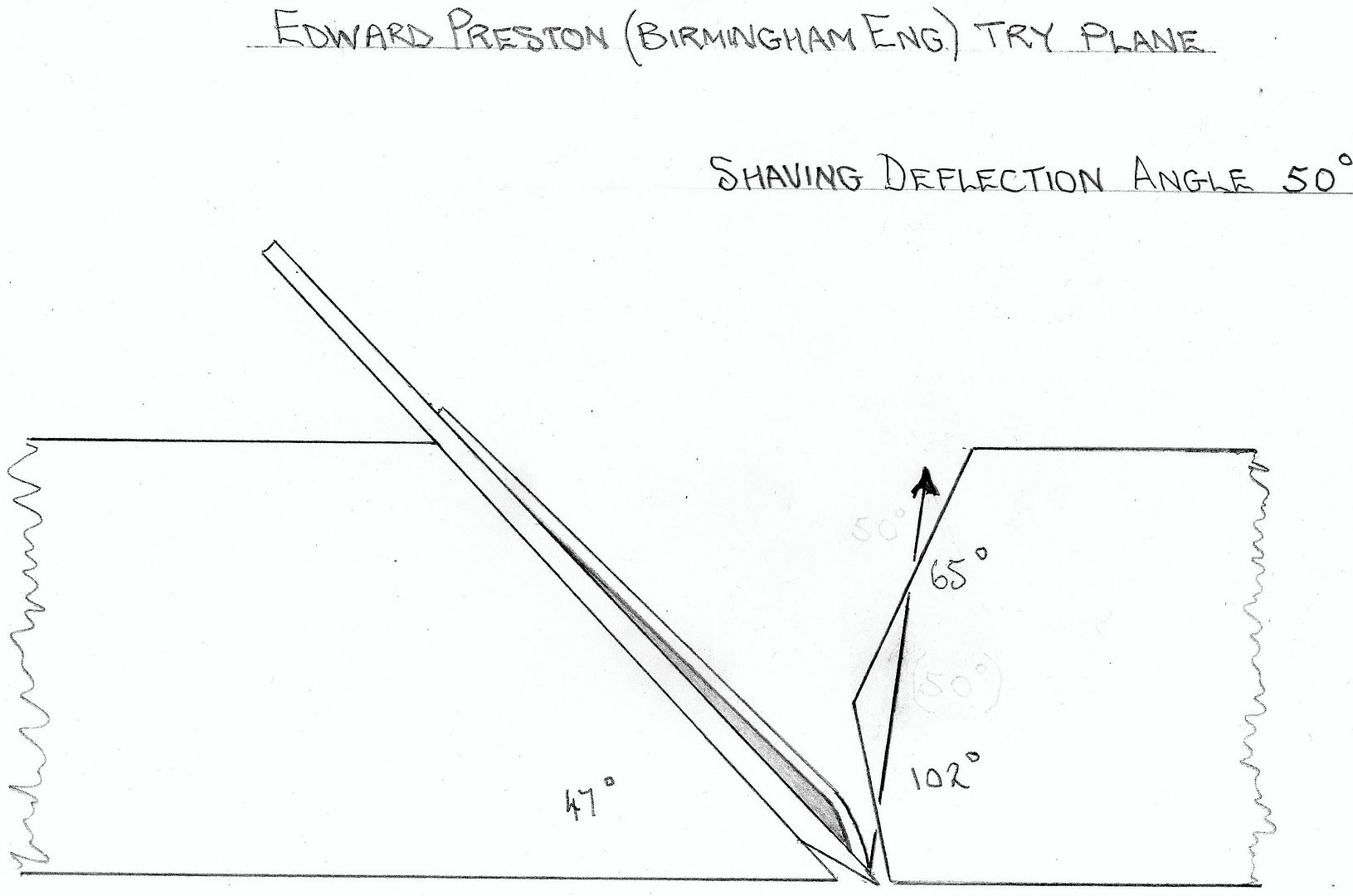

The final diagram shows the effect of further increasing the shaving defection to 50*. Note how the wear face is now serving a major role in redirecting the shaving, to the point, that may lead to a light obstruction at mouth opening to a full blockage at the mouth opening, if the user is less observant to intervene.

The question as to what is the best deflection angle for a traditional wooden plane of similar characteristics, that will not only serve to break the shaving earlier enough to mitigate tear-out, but not impede the natural flow of the shavings as it serves that vital role, is something that each user needs to experiment with.

Something to consider.

Stewie;

Moving onwards;

I have included 3 diagrams that replicate a 1/1 scale of the inner workings of the Edward Preston Try Plane that I recently posted photo's of.

The 1st drawing shows the current defection angle that was measured at 30* from the Try Planes front edge profile. The front edge of the Cap Iron shows no sign of a steeper secondary bevel being applied. Other than showing signs of being polished by its previous owners , the Cap Iron is in original condition as supplied by the planes maker.

Take special note that with a 30* shaving deflection drawn in, its parallel alignment to the wear face are near exact. Also note that at this angle of shaving deflection, the wear face poses no real obstruction to the shaving as its directed through and exits the throat of the plane.

The next diagram shows the effect of increasing that shaving defection to 40*. Note how the wear face is starting to serve some role in redirecting the shaving.

The final diagram shows the effect of further increasing the shaving defection to 50*. Note how the wear face is now serving a major role in redirecting the shaving, to the point, that may lead to a light obstruction at mouth opening to a full blockage at the mouth opening, if the user is less observant to intervene.

The question as to what is the best deflection angle for a traditional wooden plane of similar characteristics, that will not only serve to break the shaving earlier enough to mitigate tear-out, but not impede the natural flow of the shavings as it serves that vital role, is something that each user needs to experiment with.

Something to consider.

Stewie;