sploo

Somewhat extinguished member

Not sure which would be the best forum, but I suspect a metalworking audience may have the most experience in this area...

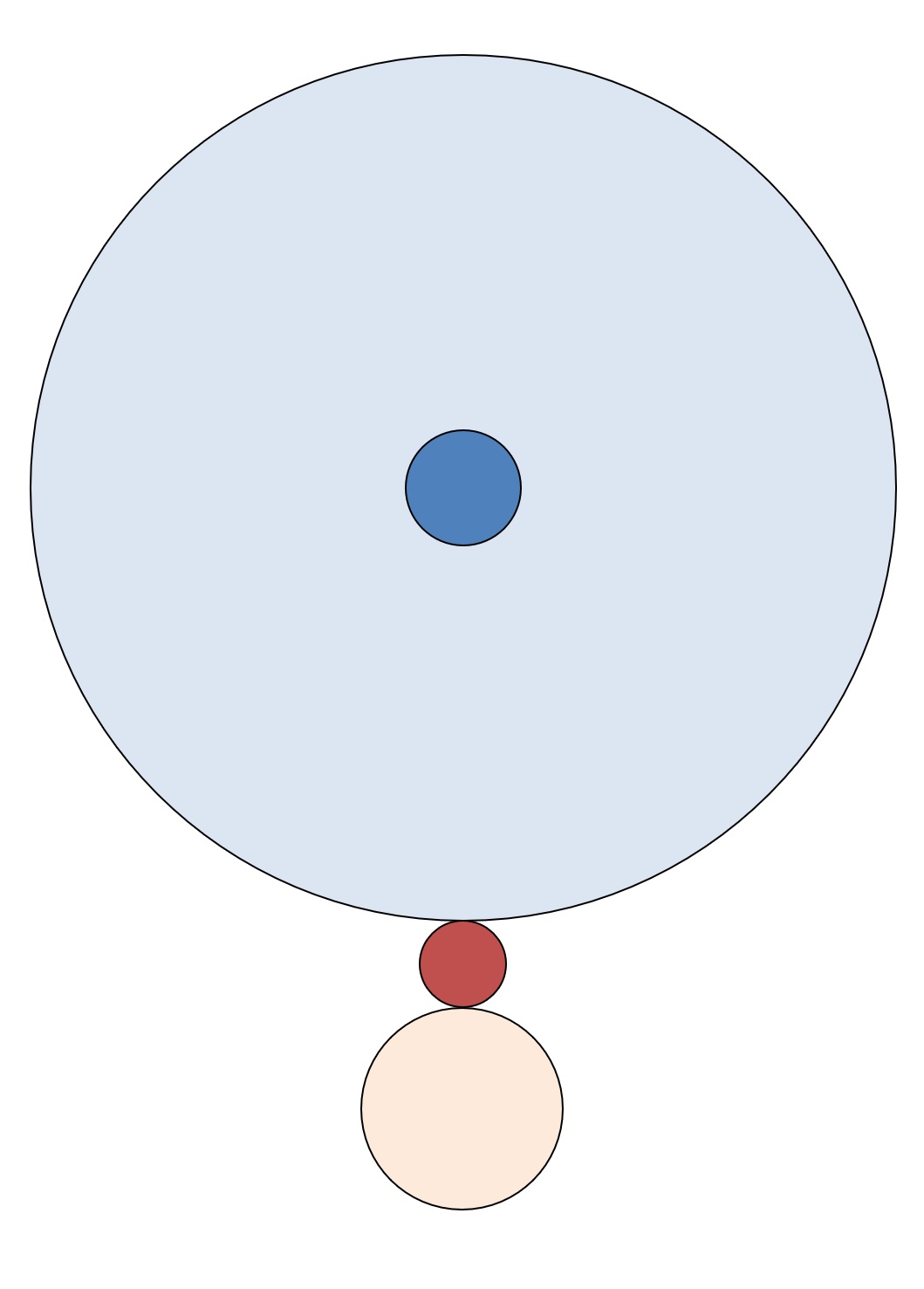

I'm building a friction drive - basically two touching metal disks for transfer of power (think cogs with no teeth). Friction drives rely on the two disks being pushed together with sufficient force to prevent slipping at the contact point - so the axles are under a lot of radial load.

I've got a prototype with a ~15mm driven disk (well, a rod) driving a 150mm disk. Speeds will be exceptionally low - the output rotating once every 24 hours; with the input obviously taking 2.4 hours.

The intended use is for a telescope tracking mount, so given UK weather it'll likely get run for only a few hours per month.

Currently I'm running the prototype on decent quality ball bearings, but I understand that bronze bushings are generally preferred for low rpm / high load applications. Anyone have experience in this area and might be able to comment?

I'm building a friction drive - basically two touching metal disks for transfer of power (think cogs with no teeth). Friction drives rely on the two disks being pushed together with sufficient force to prevent slipping at the contact point - so the axles are under a lot of radial load.

I've got a prototype with a ~15mm driven disk (well, a rod) driving a 150mm disk. Speeds will be exceptionally low - the output rotating once every 24 hours; with the input obviously taking 2.4 hours.

The intended use is for a telescope tracking mount, so given UK weather it'll likely get run for only a few hours per month.

Currently I'm running the prototype on decent quality ball bearings, but I understand that bronze bushings are generally preferred for low rpm / high load applications. Anyone have experience in this area and might be able to comment?