For my latest project I'm building another norm project. Last year I built the shaker bookcase but this now is bursting at the seams so I've decided to go build a couple of barrister ones and maybe convert the shaker one to displaying my dvd in the cinema room.

I went to a new timber supplier for me for the supplies for the project with the intension of getting white oak but on impulse came away with ash. I'm not to sure it was a good idea in hindsight :? . I'm just wondering would a barrister bookcase look right in that light a timber and if not does ash take stain well having never used it before. Opinions on that would be very welcome.

Anyway here goes with the pictures of the project to date. This is my first time going public with any of my projects so go easy on me guys :lol: .

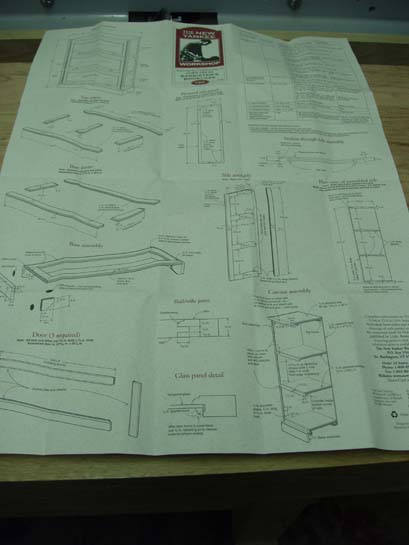

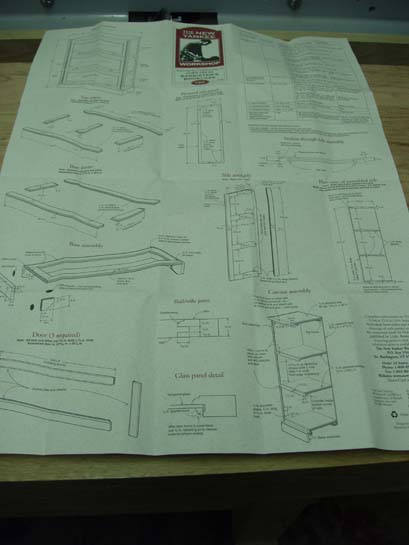

First up is the plan and timber supplies

I got started by rough cutting the solid ash to rough sizes. I use a program called Cutlist for this which I find very good.

After a bit of jointing and planning I'm ready to start working on the sides.

I started the sides by rabbiting the panels an creating a grove for the stiles and rails

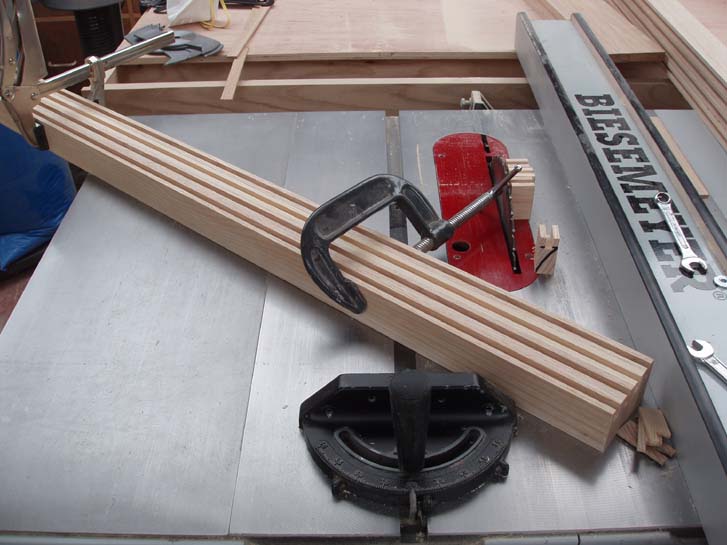

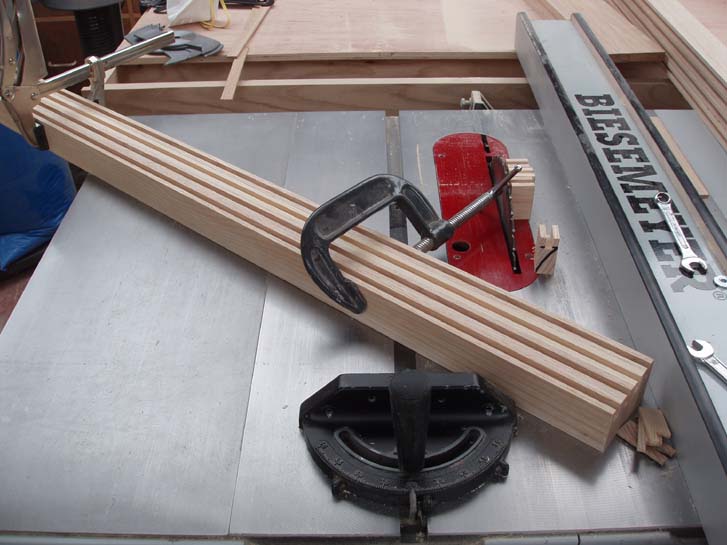

I cut all the stiles in batches of four to try and get an exact same length on all pieces. By the way for anyone who seen a previous post of mine about the rust on the tablesaw cast thanks to all the advice I got here this is a good example how is came out.

Next came the first glue up of the project and attaching the false dividers. Please ignore the lead in the second picture, I'm a spark by trade and as always that the last job that gets done in my house .

.

The four panels sanded on the outside.

Finally on the sides dadoing and rabbiting for the shelves, base and back.

I know the people around here either love dados or hate them :lol: but I can't imagine ever going back to using a router for this kind of operation. With a bit of careful setup you get a perfect fit.

Well thats it for now, hope I haven't gone overboard on the pictures. I will update in a week or so when there is a bit more progress.

Neil.

P.S. Advice on the finish, stain etc.. would be appreciated

I went to a new timber supplier for me for the supplies for the project with the intension of getting white oak but on impulse came away with ash. I'm not to sure it was a good idea in hindsight :? . I'm just wondering would a barrister bookcase look right in that light a timber and if not does ash take stain well having never used it before. Opinions on that would be very welcome.

Anyway here goes with the pictures of the project to date. This is my first time going public with any of my projects so go easy on me guys :lol: .

First up is the plan and timber supplies

I got started by rough cutting the solid ash to rough sizes. I use a program called Cutlist for this which I find very good.

After a bit of jointing and planning I'm ready to start working on the sides.

I started the sides by rabbiting the panels an creating a grove for the stiles and rails

I cut all the stiles in batches of four to try and get an exact same length on all pieces. By the way for anyone who seen a previous post of mine about the rust on the tablesaw cast thanks to all the advice I got here this is a good example how is came out.

Next came the first glue up of the project and attaching the false dividers. Please ignore the lead in the second picture, I'm a spark by trade and as always that the last job that gets done in my house

The four panels sanded on the outside.

Finally on the sides dadoing and rabbiting for the shelves, base and back.

I know the people around here either love dados or hate them :lol: but I can't imagine ever going back to using a router for this kind of operation. With a bit of careful setup you get a perfect fit.

Well thats it for now, hope I haven't gone overboard on the pictures. I will update in a week or so when there is a bit more progress.

Neil.

P.S. Advice on the finish, stain etc.. would be appreciated