Oh I looked at the Incra  For about the time it took to scroll down the page to the price

For about the time it took to scroll down the page to the price

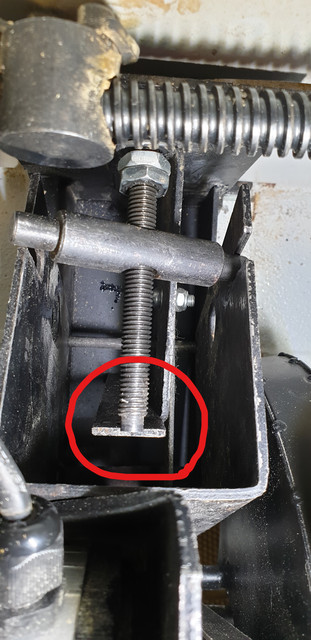

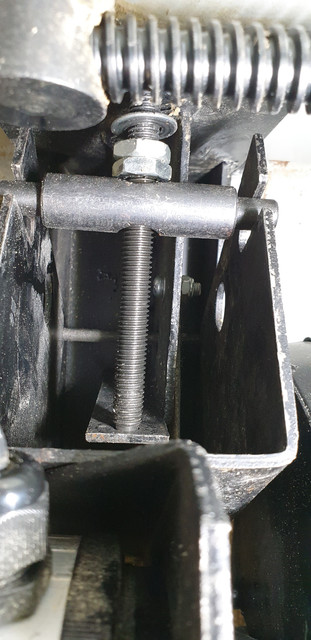

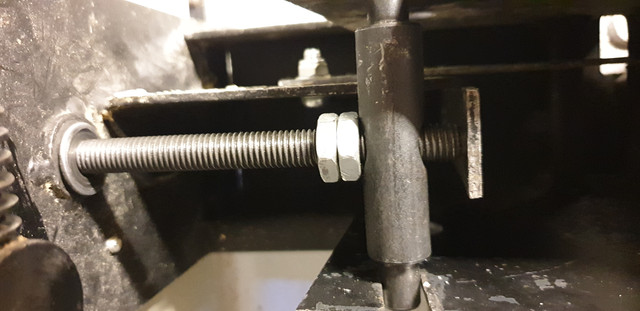

Thanks for the suggestions. Regarding the fence not going past the end of the blade. Yeah exactly, I read something like that but I took it further, mine stops at the half way point of the blade, the thinking being the cut has finished then and it's kickback zone from there on? It's this which is making me think my cuts are push and hope as the material goes past that. I don't like it. I need to make more measurements to know how much it actually matters.

Maybe I just need to try moving the fence to the back of the blade instead of the middle.

Thanks for the suggestions. Regarding the fence not going past the end of the blade. Yeah exactly, I read something like that but I took it further, mine stops at the half way point of the blade, the thinking being the cut has finished then and it's kickback zone from there on? It's this which is making me think my cuts are push and hope as the material goes past that. I don't like it. I need to make more measurements to know how much it actually matters.

Maybe I just need to try moving the fence to the back of the blade instead of the middle.