MarkDennehy

Established Member

Remember Mark, type "l" and not "r" by mistake...

So I have this project in mind (shelves) but I can already see this awkward bit in the construction and I'm looking for ideas to get round it.

Picture if you will, a normal bookshelf with housing joints and two to three shelves. Easy to clamp up if you have to, easy to drive the shelf into the dado with a mallet as well.

Now curve the front of the bookshelves out in a nice graceful curve across the front (keep the back edges simple and straight). Still easy enough to assemble.

Now curve the front edges of the sides of the bookcase so they have a nice graceful curve from floor to the top of the bookcase. Still readily doable though the mallet is now the easier option than the clamps.

Now angle the two sides of the bookcase outward by, say, 15 degrees or so (so they're still vertical, but each is rotated around a vertical axis running through the back corner of the bookcase).

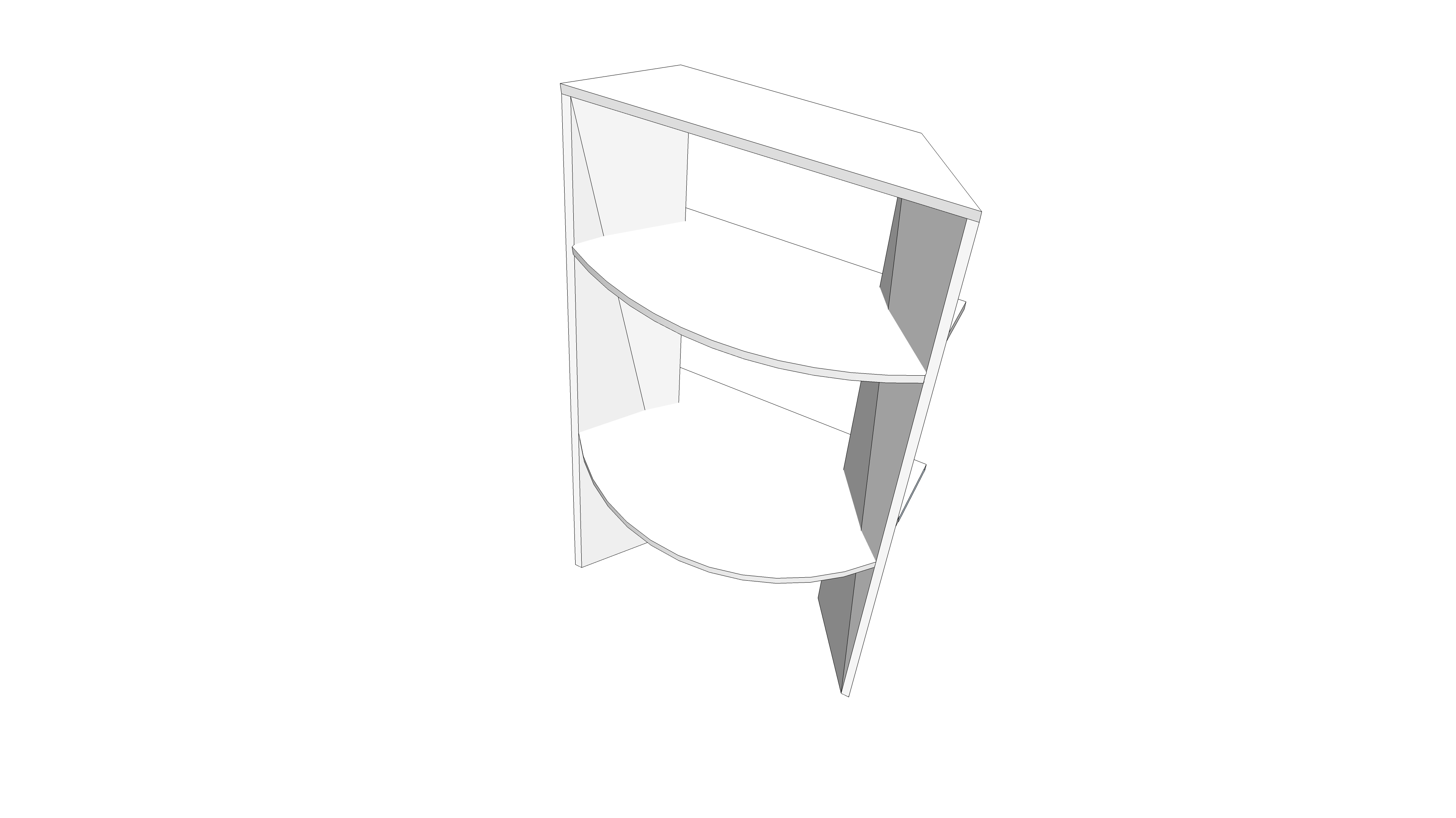

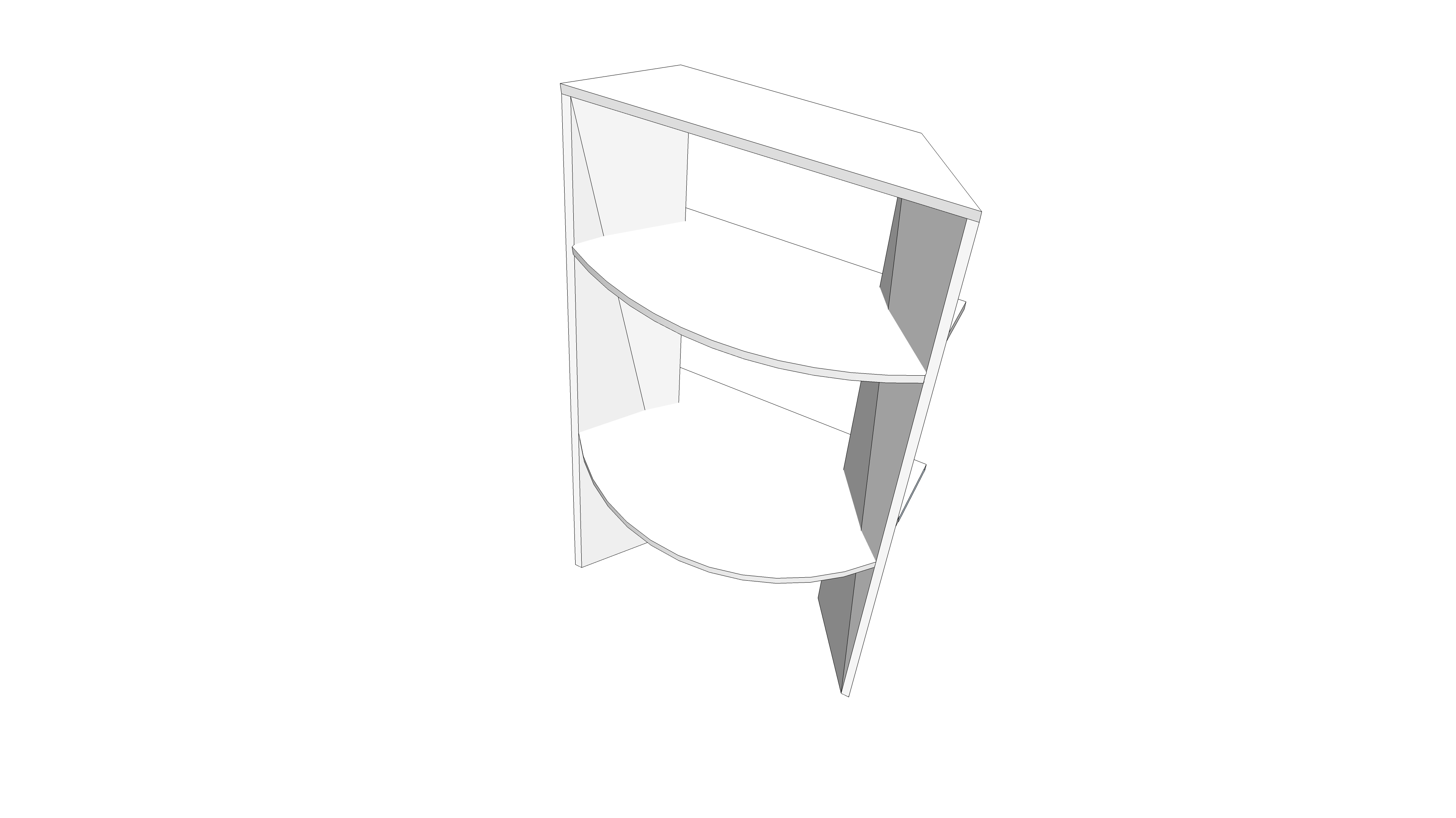

The design now looks beautiful, it has a few functional good points I don't want to lose because of the intended final application. Very, very roughly (missing several curves, with exaggerated angles, and ignore the bits outside the sides as that's just me having issues with sketchup as I'm rusty using it), it looks like this in my head:

But...

How the pineapple do I clamp the shelf into the housing joint? Or mallet the shelf home?

I'm running through a few idea in my head, but not having done this before, I can see myself standing in the shed with components that are marginally too large to work on comfortably, staring at curing glue and a joint that won't seat and no way to convince it to do so, and I'd rather avoid that one Has anyone come across this problem and solved it before? Would ye mind telling me the secret?

Has anyone come across this problem and solved it before? Would ye mind telling me the secret?

Thanks!

So I have this project in mind (shelves) but I can already see this awkward bit in the construction and I'm looking for ideas to get round it.

Picture if you will, a normal bookshelf with housing joints and two to three shelves. Easy to clamp up if you have to, easy to drive the shelf into the dado with a mallet as well.

Now curve the front of the bookshelves out in a nice graceful curve across the front (keep the back edges simple and straight). Still easy enough to assemble.

Now curve the front edges of the sides of the bookcase so they have a nice graceful curve from floor to the top of the bookcase. Still readily doable though the mallet is now the easier option than the clamps.

Now angle the two sides of the bookcase outward by, say, 15 degrees or so (so they're still vertical, but each is rotated around a vertical axis running through the back corner of the bookcase).

The design now looks beautiful, it has a few functional good points I don't want to lose because of the intended final application. Very, very roughly (missing several curves, with exaggerated angles, and ignore the bits outside the sides as that's just me having issues with sketchup as I'm rusty using it), it looks like this in my head:

But...

How the pineapple do I clamp the shelf into the housing joint? Or mallet the shelf home?

I'm running through a few idea in my head, but not having done this before, I can see myself standing in the shed with components that are marginally too large to work on comfortably, staring at curing glue and a joint that won't seat and no way to convince it to do so, and I'd rather avoid that one

Thanks!