OPJ

Established Member

Yes, the deadline for all part two competition entries may be along way behind us now but, after a couple of previously documented planer-thicknesser problems, Wednesday 20th February 2008 was the day my belated Arts & Crafts-style Oak TV Stand finally began!

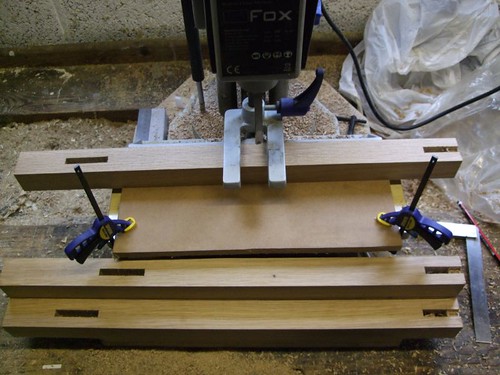

So. This first shot shows the components for the basic frame (excluding the slats, top and two shelves) planed up and ready to go. It's been sat in my bedroom sine October so, even without a moisture meter, I know it has to be dry enough.

And yes, I tend to use my bandsaw for more than half the jobs my workbench should be used for!

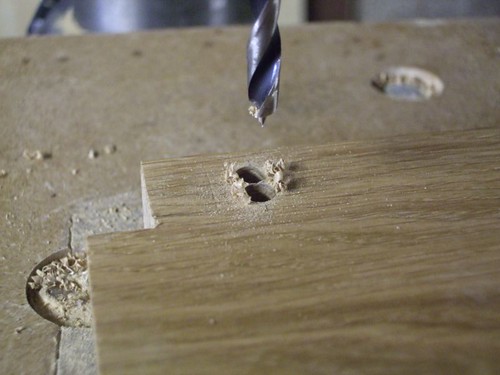

First job was to mark up the legs and cut the mortises on my Fox morticer. First time I've properly used it and it did a great job - perhaps that also had something to do with the good quality Japanese chisels.

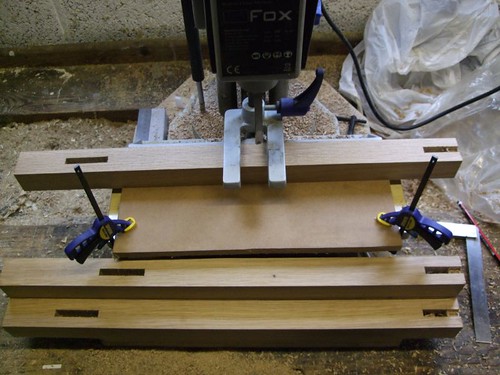

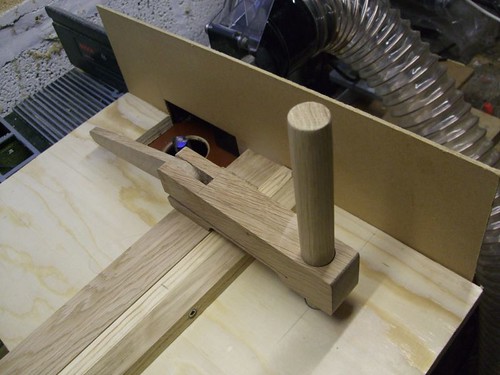

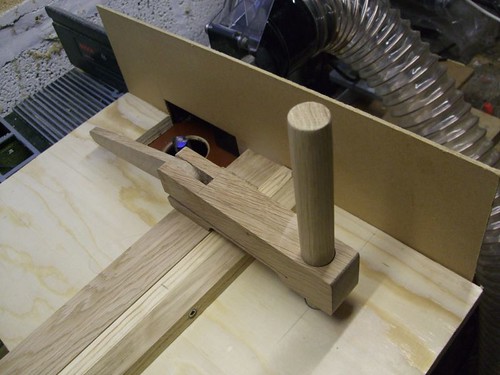

With all the mortices cleaned up, it's time to get ready for some tennoning usng my adaptation of Steve Maskery's excellent router table jig. Worked like a treat, even though my Bosch table is convex along its length!

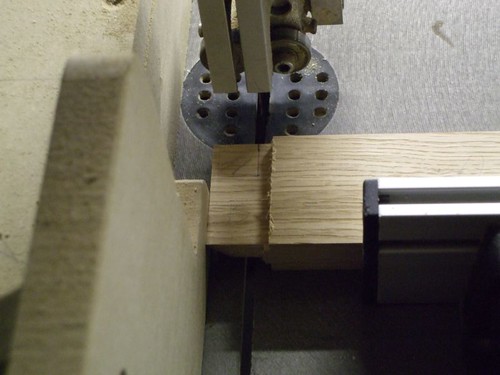

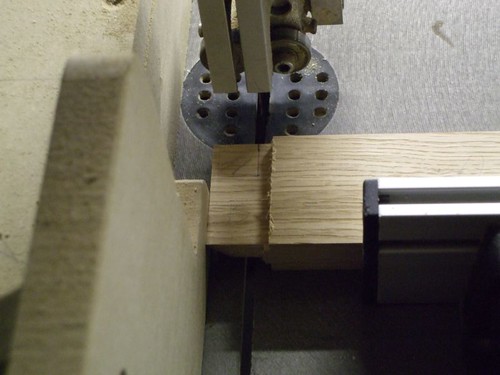

Once both sets of rails were done, it was time to cut the haunches. I chose the bandsaw, using my short rip fence as a stop - another adaptation from one of Steve's great ideas. :wink:

Then, it was time to cut a 45º angle on the ends of the top rails and cut the lower rails to length at 90º, on my monstrous 12" Bosch SCMS. Here's the finished result of the top rails.

Before I could think about dry-assembling the frame, it was time for a mistake! Back to the router table we go; it's time to rout the 3/8" grooves for the 19mm thick buttons - which will be cut from the offcuts you saw in the first photo.

Back to the router table we go; it's time to rout the 3/8" grooves for the 19mm thick buttons - which will be cut from the offcuts you saw in the first photo.

Because I changed the design slightly (you'll see a little later), didn't need to rout a groove in the two lower side rails, as they're going to sit higher than the shelf, which will only rest on the front and back rails. :roll:

Next job was to dry-assemble the frame then, in order to get the shoulder-to-shoulder length for these slats, which will run vertically in each of the two sides. Tenons, again, cut on the router table. I did contemplate doing them on the bandsaw, just for a change, but hey, why do something differently when it worked great the first time!

And it goes together a little something like this! :wink:

And then, like this - it'll still need finishing and fitting of the two shelves before I even consider gluing it up.

How am I going to support the shelf, you may be thinking...

Well, I'm still not entirely certain about that. I intend to add a little corbel [posh word for bracket!] to each corner, dowelled to the inside of each leg. Probably dowelled up in to the base of the shelf as well, with an elongated hole for expansion/contraction.

I decided that sticking two blanks together with double-sided tape would make it easier - fitting the 8mm dowels dry now made it much easier - and safer - cutting them on the bandsaw.

--------------

Well, that's as much as I'm able let you see right now. :wink:

Since then though, managed to get the two shelves glued up with the aid of my lovely new Makita biscuit jointer and I've given all the frame components a first coat of Danish Oil.

The Bosch saw cut the 9"x1" oak better than I could ever have done better and easier than I could do by hand! Really like the toggle clamp. Didn't get this until November - how would I have managed without it?!

I still need to cut the buttons though - and I'd appreciate anyone's advice on the best way to do this - I reckon I need... ten of them, minimum.

There's still time to change the support for the middle shelf - if you have any other ideas, I'd like to hear from you. I'm contemplating adding a row of dowels to the inside faces of the slats but, that'd require VERY accurate drilling...! :?

Thanks must also go to Philly for modifying my morticer bush. I wouldn't have been able to use my lovely Japanese chisels without his help!

Thanks for reading. I'll get an update for you when I can. :wink:

:wink:

So. This first shot shows the components for the basic frame (excluding the slats, top and two shelves) planed up and ready to go. It's been sat in my bedroom sine October so, even without a moisture meter, I know it has to be dry enough.

And yes, I tend to use my bandsaw for more than half the jobs my workbench should be used for!

First job was to mark up the legs and cut the mortises on my Fox morticer. First time I've properly used it and it did a great job - perhaps that also had something to do with the good quality Japanese chisels.

With all the mortices cleaned up, it's time to get ready for some tennoning usng my adaptation of Steve Maskery's excellent router table jig. Worked like a treat, even though my Bosch table is convex along its length!

Once both sets of rails were done, it was time to cut the haunches. I chose the bandsaw, using my short rip fence as a stop - another adaptation from one of Steve's great ideas. :wink:

Then, it was time to cut a 45º angle on the ends of the top rails and cut the lower rails to length at 90º, on my monstrous 12" Bosch SCMS. Here's the finished result of the top rails.

Before I could think about dry-assembling the frame, it was time for a mistake!

Because I changed the design slightly (you'll see a little later), didn't need to rout a groove in the two lower side rails, as they're going to sit higher than the shelf, which will only rest on the front and back rails. :roll:

Next job was to dry-assemble the frame then, in order to get the shoulder-to-shoulder length for these slats, which will run vertically in each of the two sides. Tenons, again, cut on the router table. I did contemplate doing them on the bandsaw, just for a change, but hey, why do something differently when it worked great the first time!

And it goes together a little something like this! :wink:

And then, like this - it'll still need finishing and fitting of the two shelves before I even consider gluing it up.

How am I going to support the shelf, you may be thinking...

Well, I'm still not entirely certain about that. I intend to add a little corbel [posh word for bracket!] to each corner, dowelled to the inside of each leg. Probably dowelled up in to the base of the shelf as well, with an elongated hole for expansion/contraction.

I decided that sticking two blanks together with double-sided tape would make it easier - fitting the 8mm dowels dry now made it much easier - and safer - cutting them on the bandsaw.

--------------

Well, that's as much as I'm able let you see right now. :wink:

Since then though, managed to get the two shelves glued up with the aid of my lovely new Makita biscuit jointer and I've given all the frame components a first coat of Danish Oil.

The Bosch saw cut the 9"x1" oak better than I could ever have done better and easier than I could do by hand! Really like the toggle clamp. Didn't get this until November - how would I have managed without it?!

I still need to cut the buttons though - and I'd appreciate anyone's advice on the best way to do this - I reckon I need... ten of them, minimum.

There's still time to change the support for the middle shelf - if you have any other ideas, I'd like to hear from you. I'm contemplating adding a row of dowels to the inside faces of the slats but, that'd require VERY accurate drilling...! :?

Thanks must also go to Philly for modifying my morticer bush. I wouldn't have been able to use my lovely Japanese chisels without his help!

Thanks for reading. I'll get an update for you when I can.