http://www.woodcentral.com/woodworking/ ... -v11-test/

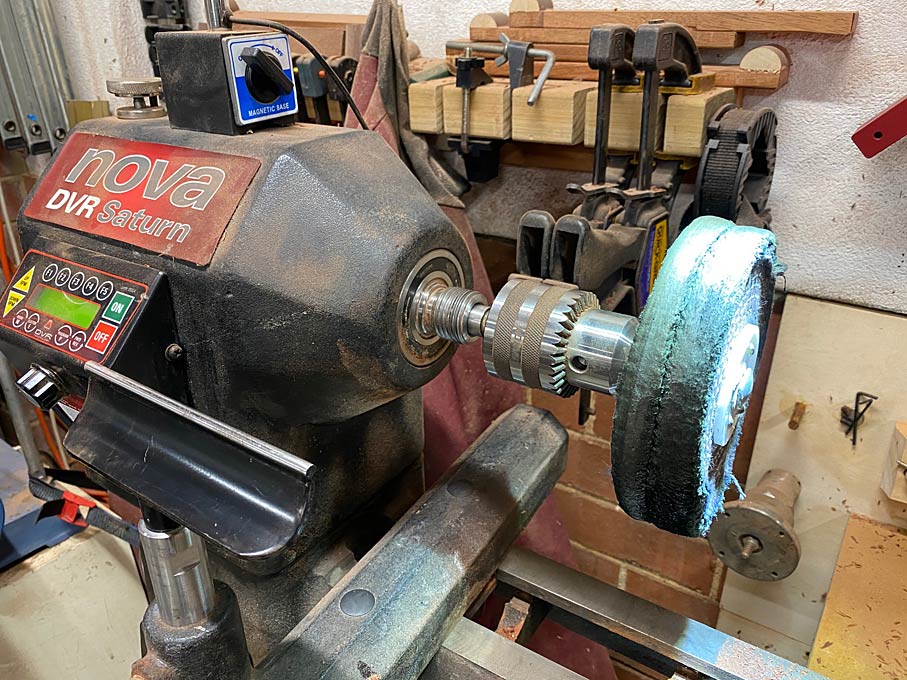

Winston Chang is a fellow in the US who has been experimenting with the buffer since I brought this up.

Derek Cohen's testing suggested that the V11 chisel held up better than most in more standard sharpening regimes. I suspect that derek's test illustrated hardness more than steel type (V11 is probably slightly less tough than carbon steel, but the hardness range that LV makes these chisels in separates them from their O1 offering, which are spec a little bit too soft for woodworking use - at least optimally)

Because of Derek's testing, I chose to order a V11 chisel before I run a test of all of this stuff and write an article. I have had V11 irons before so I suspect the V11 chisel will work about as well as an AI Mk2, another chisel that I will test. They are relatively similar in hardness.

Since the V11 chisels are generally considered over here to be a top of the market offering and not everyone is familiar with the wonderful AI MK2 chisels, I'll be testing both (if I didn't include V11, the instant reaction would be "V11 probably would've been fine without this")

For the same reason, I will also include a japanese chisel (assertion that japanese tools never fail is almost immediate if you don't show proof)

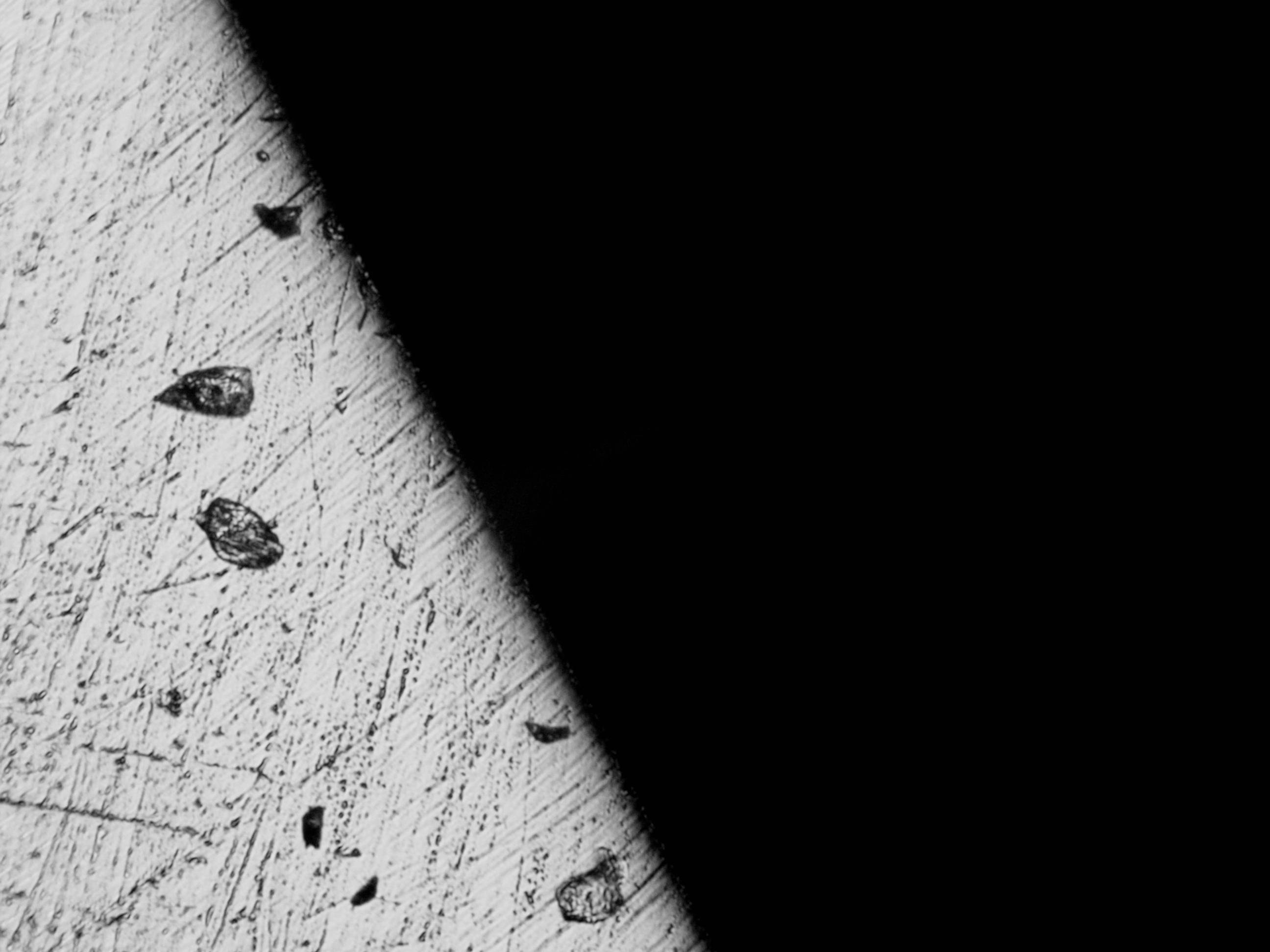

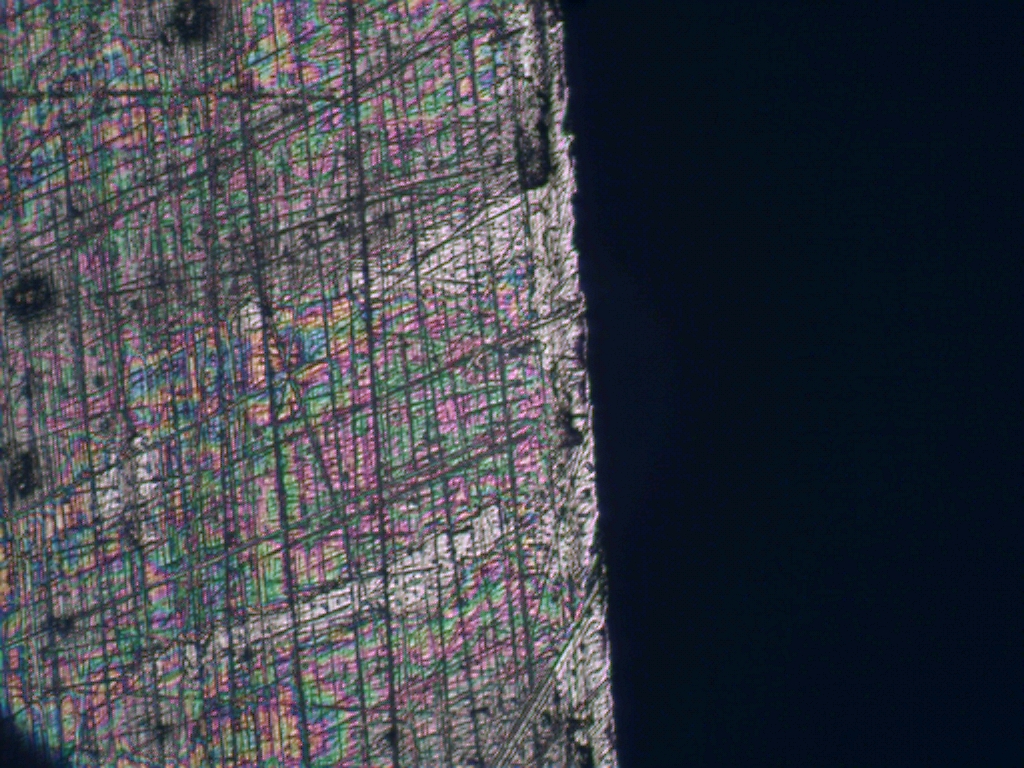

I've actually never seen any flat honed chisel that doesn't suffer some of these typical types of damage in hardwood unless the final edge gets very steep ( a leave that shoots chips off of hardwoods usually more so than laying over leaves of wood when chopping, and that's annoying)

At any rate, winston finds the buffed buck brothers hardware store chisel to hold up fine, while the V11 chisel shows hard chisel tendencies at the edge at 30 degrees. I will repeat this and also find the level where each of these chisels holds up well with flat bevels, the associated work with each, and then the ability of a shallower bevel to be buffed and hold up at least as well and be less work.

We haven't yet found any reasonable chisel that won't hold an edge well in maple once the edge has been buffed into this small rounded element.

I think winston is more focused on edge holding and less on taking advantage of subsequent slimming of the bevel behind the edge, but it's there to take for free and I'll show that by counting controlled strikes in testing.

Separately, I believe that for the folks who like flat bevels and who have been led by magazine or blog tests to "buy up" because they had a chisel that just showed itself to not hold up in work, an extra 2 degrees of microbevel generally solves the problem between expensive and cheap chisels.

Winston Chang is a fellow in the US who has been experimenting with the buffer since I brought this up.

Derek Cohen's testing suggested that the V11 chisel held up better than most in more standard sharpening regimes. I suspect that derek's test illustrated hardness more than steel type (V11 is probably slightly less tough than carbon steel, but the hardness range that LV makes these chisels in separates them from their O1 offering, which are spec a little bit too soft for woodworking use - at least optimally)

Because of Derek's testing, I chose to order a V11 chisel before I run a test of all of this stuff and write an article. I have had V11 irons before so I suspect the V11 chisel will work about as well as an AI Mk2, another chisel that I will test. They are relatively similar in hardness.

Since the V11 chisels are generally considered over here to be a top of the market offering and not everyone is familiar with the wonderful AI MK2 chisels, I'll be testing both (if I didn't include V11, the instant reaction would be "V11 probably would've been fine without this")

For the same reason, I will also include a japanese chisel (assertion that japanese tools never fail is almost immediate if you don't show proof)

I've actually never seen any flat honed chisel that doesn't suffer some of these typical types of damage in hardwood unless the final edge gets very steep ( a leave that shoots chips off of hardwoods usually more so than laying over leaves of wood when chopping, and that's annoying)

At any rate, winston finds the buffed buck brothers hardware store chisel to hold up fine, while the V11 chisel shows hard chisel tendencies at the edge at 30 degrees. I will repeat this and also find the level where each of these chisels holds up well with flat bevels, the associated work with each, and then the ability of a shallower bevel to be buffed and hold up at least as well and be less work.

We haven't yet found any reasonable chisel that won't hold an edge well in maple once the edge has been buffed into this small rounded element.

I think winston is more focused on edge holding and less on taking advantage of subsequent slimming of the bevel behind the edge, but it's there to take for free and I'll show that by counting controlled strikes in testing.

Separately, I believe that for the folks who like flat bevels and who have been led by magazine or blog tests to "buy up" because they had a chisel that just showed itself to not hold up in work, an extra 2 degrees of microbevel generally solves the problem between expensive and cheap chisels.