JonnyD

Established Member

Its been a while since i did a project on here so here goes. Basically its going to be a walnut veneered birch ply carcased kitchen with a painted beech front.

I ordered about 65m2 of black walnut veneer from capital crispins and got 4 sequential packs of veneer from 250mm to 320mm wide. First job was to crosscut the veneer pack to the required length which was done on the table saw.

A piece of sacrificial mdf is held ontop of the pack to help keep it flat when cutting

Over the years ive jointed the veneer in many ways using the planer, festool saw, panel saw but i find the best way is to use the shooting board.

The board is as basic as it comes a piece of mfc with some 9mm mrmdf screwed to it which is screwed down to the bench to stop it moving.

The veneer pack is placed on the jig with 3mm ish overhang

A 25mm piece of mdf is then placed on top

The problem with edging any veneers is keeping the veneers from sliding around whilst they are being jointed. The mezzanine floor above the bench comes in very handy here and a few few props are absolutely brilliant at keeping the veneer in place and clamping the veneers together so you can shoot a perfect edge and very quick to setup.

I used to use my stanley no 7 but the LAJ is now weapon of choice

Just plane away until the plane stops cutting and your done 24 leaves at a time

your left with lots of fine shavings

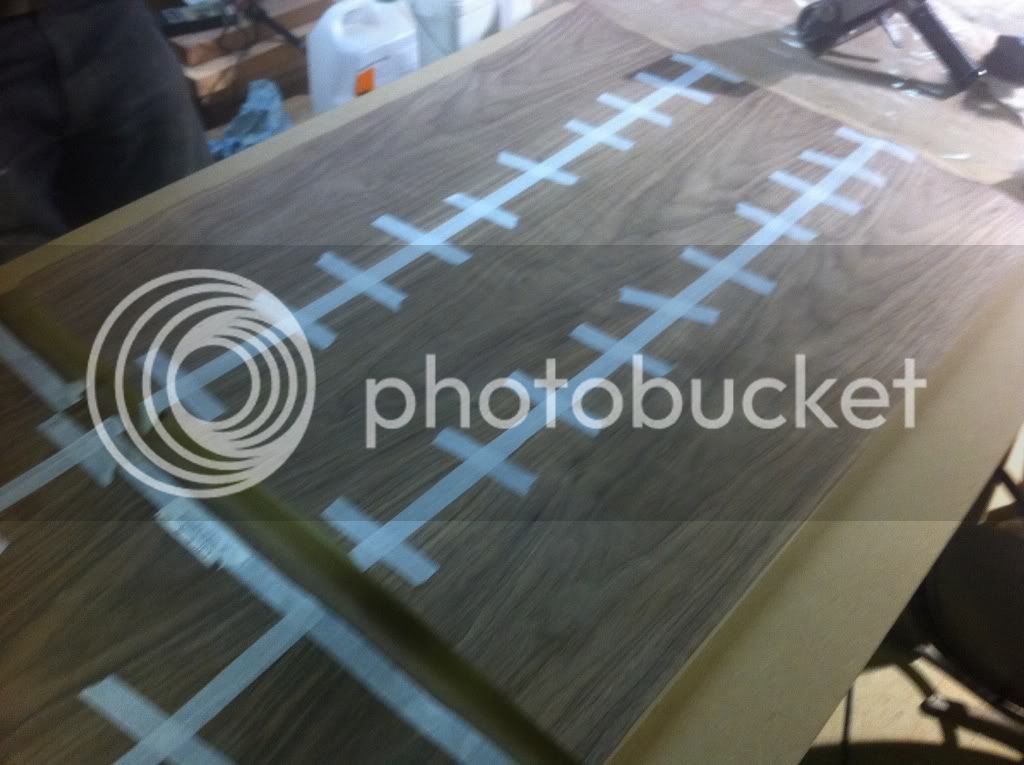

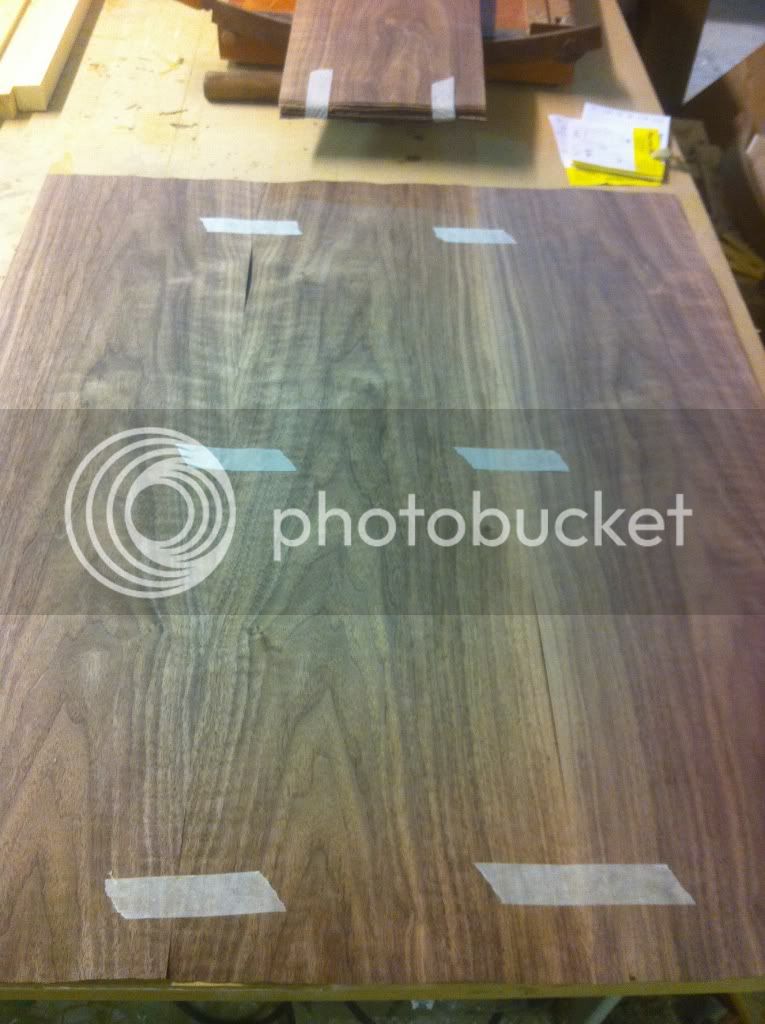

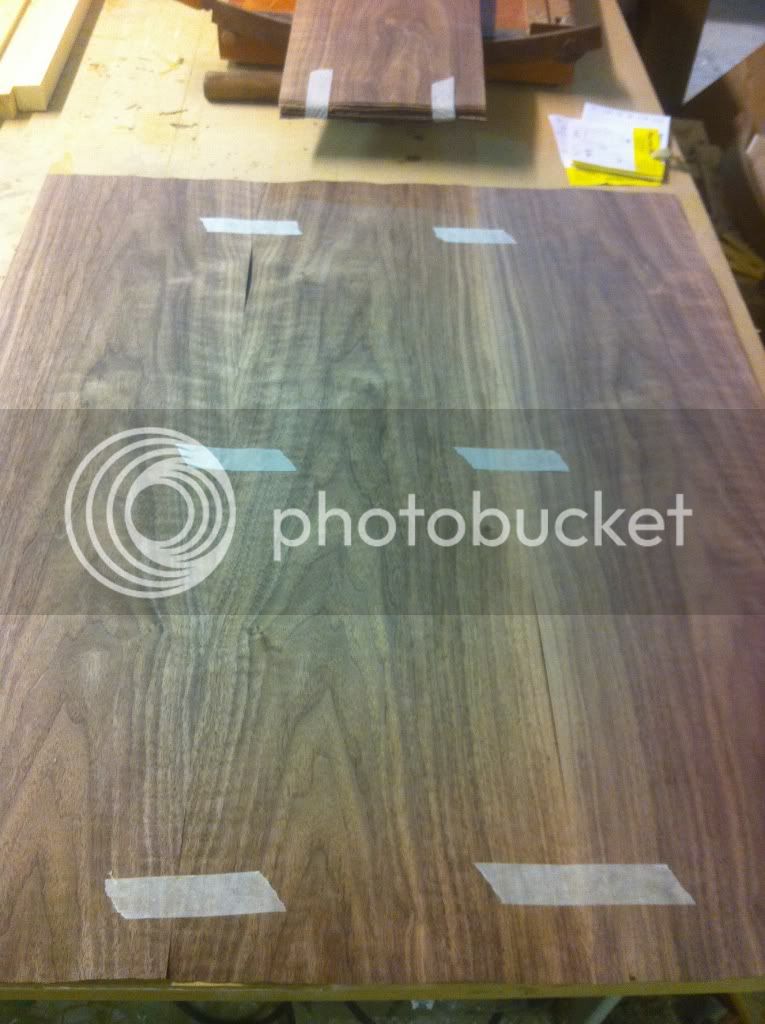

The panels can now be joined together starting with some masking tape to temporarily hold them

veneer tape is then put across the edge at about 100mm centres

the masking tape is then removed and veneer tape put along the seams

the back

Ive got about 70 layons jointed up ready and the glue was delivered today so hopefully pressing will start tomorrow

DougB kindly turned me a sample knob which we then had made on a copy lathe and have made some supports to allow them to be painted gloss black

Thanks for looking

cheers

Jon

I ordered about 65m2 of black walnut veneer from capital crispins and got 4 sequential packs of veneer from 250mm to 320mm wide. First job was to crosscut the veneer pack to the required length which was done on the table saw.

A piece of sacrificial mdf is held ontop of the pack to help keep it flat when cutting

Over the years ive jointed the veneer in many ways using the planer, festool saw, panel saw but i find the best way is to use the shooting board.

The board is as basic as it comes a piece of mfc with some 9mm mrmdf screwed to it which is screwed down to the bench to stop it moving.

The veneer pack is placed on the jig with 3mm ish overhang

A 25mm piece of mdf is then placed on top

The problem with edging any veneers is keeping the veneers from sliding around whilst they are being jointed. The mezzanine floor above the bench comes in very handy here and a few few props are absolutely brilliant at keeping the veneer in place and clamping the veneers together so you can shoot a perfect edge and very quick to setup.

I used to use my stanley no 7 but the LAJ is now weapon of choice

Just plane away until the plane stops cutting and your done 24 leaves at a time

your left with lots of fine shavings

The panels can now be joined together starting with some masking tape to temporarily hold them

veneer tape is then put across the edge at about 100mm centres

the masking tape is then removed and veneer tape put along the seams

the back

Ive got about 70 layons jointed up ready and the glue was delivered today so hopefully pressing will start tomorrow

DougB kindly turned me a sample knob which we then had made on a copy lathe and have made some supports to allow them to be painted gloss black

Thanks for looking

cheers

Jon