Monkey Mark

Established Member

Morning all,

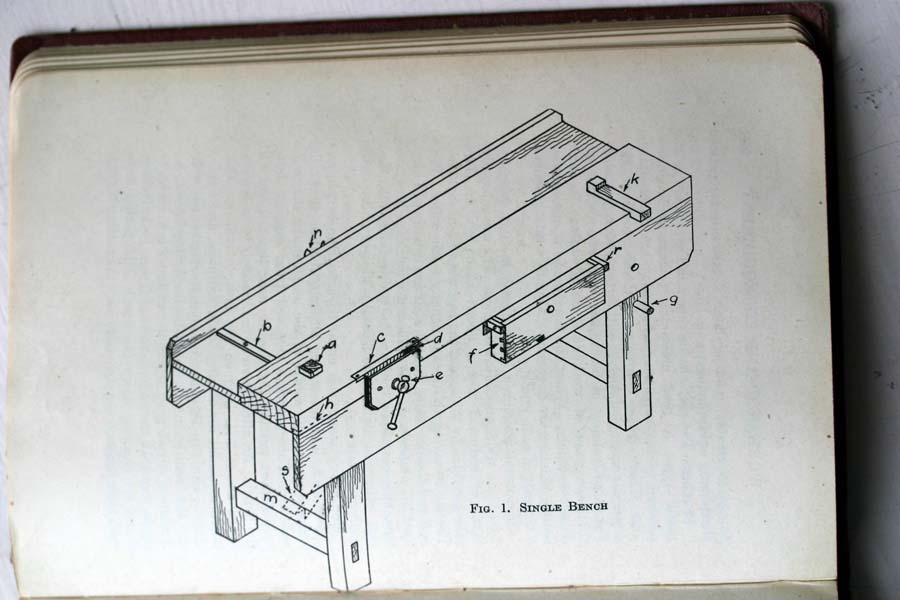

I'm thinking of building my first work bench. So far i've just used whatever ive had at hand like kitchen worktops, workmates etc.

I'd like something thats not too difficult to make (without a workbench, its harder to make a work bench :mrgreen: ). And, due to space, something that can be mobile.

I saw this plan https://club.craftsman.com/projects...YouTube&utm_medium=video&utm_campaign=project

Any thoughts on this or suggestions for others? Any recommendations as to which wood is typically the best?

I'm thinking of building my first work bench. So far i've just used whatever ive had at hand like kitchen worktops, workmates etc.

I'd like something thats not too difficult to make (without a workbench, its harder to make a work bench :mrgreen: ). And, due to space, something that can be mobile.

I saw this plan https://club.craftsman.com/projects...YouTube&utm_medium=video&utm_campaign=project

Any thoughts on this or suggestions for others? Any recommendations as to which wood is typically the best?