Amendment to previous answer, just popped down to have a look.

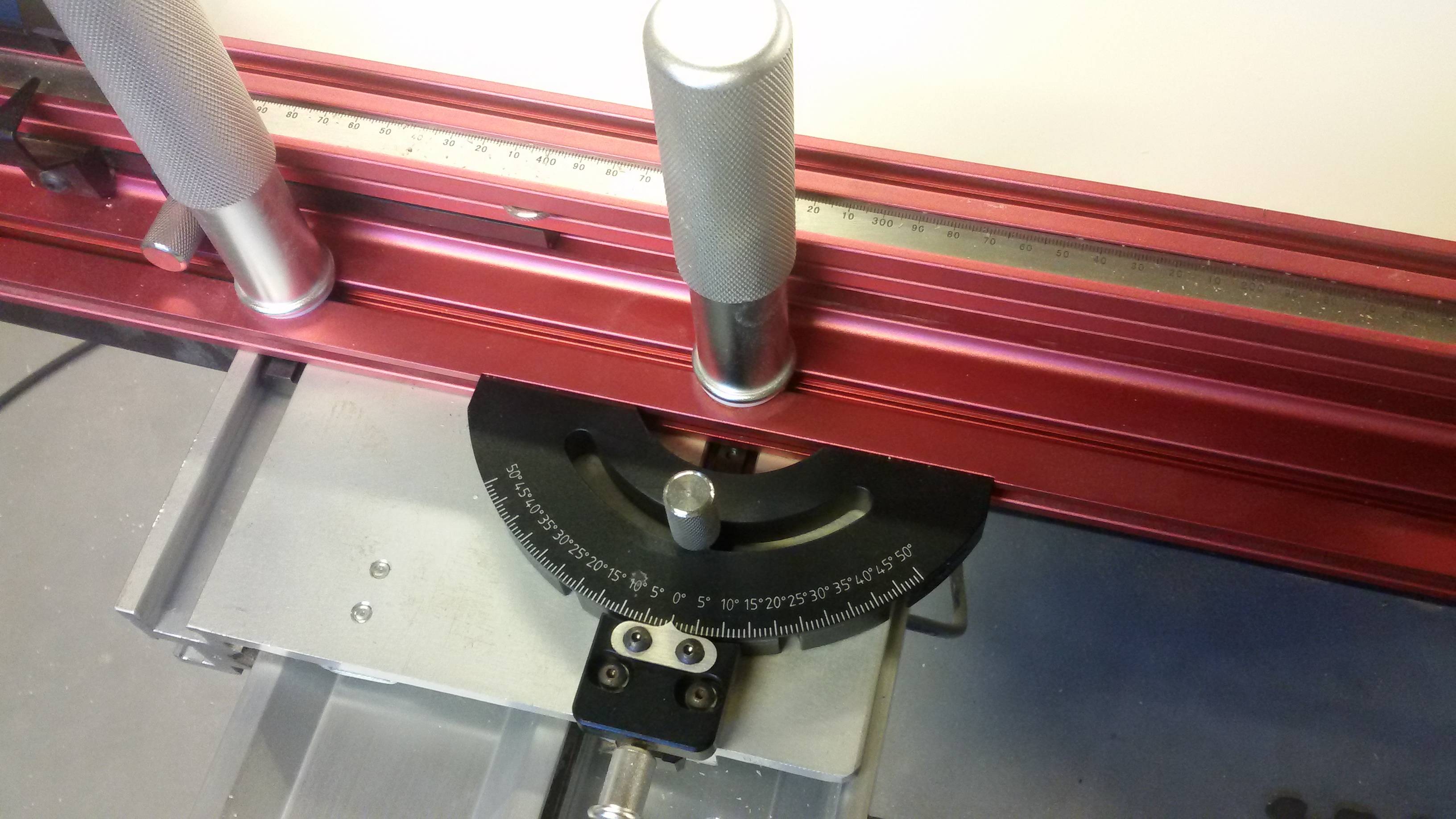

I did not need to cut the rails, as they have holes in the correct position, however I did have to cut out two small sections for mitre slots - only needed if your sledges and so on have the mitre come out the front.

The back rail did not need this modification as it sits below the level

The box section I cut a little bit off.

With the rails and box aligned to the left, as close to the sliding table as possible, I get 88cm possible right side cut with the fence. The fence will go further to the right as the rails / box are moved to the right.

In terms of one way trip, I don't think you need worry. If you revert to left wing, then you will simple lose some box section on the left, which means if you put the fence on the left, it won't go so far. I never put the fence on the left. Ever. So would not be a problem at all, I'd probably leave where it is now to get more space on the right.

However as it's longer to the right, the tape is not long enough, so move the mark to the right side, and put tape on, and you can have tape right up to 90cm mark. I didn't do this, so I get up to 75, then have to measure after. (I moved the tape, however I'd already cut it with the marker on the left)

In terms of getting on with sliding table, I love it, I can't imagine not having it. The only downside is that with the square fence in place, you get about 10cm clearance on the left of the blade. If you pull the table back, you have about 1.5m from mitre fence to blade. So, if you cut a board that's more than 1.5m long, and you're cutting off more than 10cm from left side, it gets in the way. You can remove the mitre fence, however I spend hours getting it square, so I never do that. It also means I don't use it for angles, unless I have a big project with lots of precise angle cuts.

I cut larger boards to rough size with tracksaw anyway, so none of this is really a problem.

One other slight downside with sliding table is that the power switch is behind you when working at table, however again, not a big deal.

I don't use a dado stack, although I am seriously considering it. Watching Marc Spagnolo and Steve Ramsey makes me want one. Reading all the UK stories about why they're bad puts me off. I think I would probably get the one from woodford though, as it's definitely going to fit, and I wouldn't use it enough to need something very expensive.

You probably need an outfeed table at the back. I built one on wheels which is also a cupboard, so I can move to where I need based on size of material. With all that in place and the S/T, the footprint is quite high - for an ideal set up.

With all that in place though, I have a pretty amazing set up, and I am sure you'll enjoy it too!

Just lay out your box and rails and think hard what you're doing before you cut anything!!