Chris,

Yes I will dig out the article and post the link here when I find it.

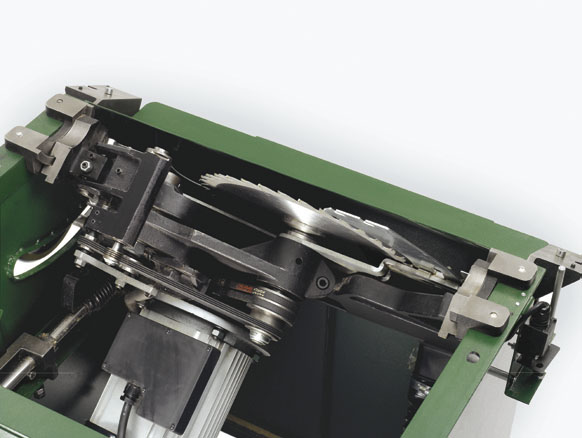

Wizer, I know you have said before how you are not keen on this type of sliding carriage ( format type to give it its proper title) that has no fixed surface to the left of the blade, and I gave a full explanation of why this type is superior to the add on type in a previous thread. It may be prudent to paste that here so that Chris can consider the pros and cons of both types, but frankly from what he says he needs the machine to do I doubt he is going to meet those needs with a full top saw with an aftermarket slider, as most of the usual semi-pro machines are.

The Record TS315 is a decent piece of kit for the price but you can get the same machine with a different badge a good few hundred pound cheaper, but with one years warranty as opposed to Records admirable 5 year deal. As for the scoring blade on that machine , just take it off. If you remove the scoring drive gear you can fit a 12" blade if you want to, although I prefer 10" but only because the dozen different blades I have are all 10"

I also looked at the Deft, and it looks a fine piece for the money apart from as you say the lack of a sliding table. If this ever gets one it will be a bolt on and an afterthought, unless the machine is redesigned from scratch, and then the price will be edging towards a felder.

So its a question of getting the most for your money. and the nearest saw mentioned so far is the Record, but be prepared for lots of flack on here or any other woodworking site if you speak kindly of Record, because there is a tendency for people to condemn these machines because of a few negative reports or comments both from users and from those who are prepared to make a judgement without actually having any direct experience of the machine.........They heard it "somewhere" so it must be right.., and the fact that they are built in China. You would do best to ignore the prejudice and look at the specifications and speak to users who are happy with them.

Until last year I used a Scheppach 2500, which is a decent machine , but somewhat dainty, the sliding carriage on Scheppachs is great for trimming but hopeless for panel work. and the engineering is not that great. adequate yes, but after using Scheppach for 15 years I can tell you its not the bees knees its cracked up to be.

and there is one thing common to all these machines: They ALL require fettling, tweaking, setting up, call it what you will but none are great when first built out of the crate. So you might as well fettle something that will have the capacity to do the work you want it to when its up and running,

Forget gimmicks like magnifying lens on the rip fence, I could quite happily do without a rule stuck on the rip fence rail, I always use a tape measure to set up and final adjust and its right. and ignore folk that inspect a table top and comment that its a 5000th of an inch hollow in a certain spot , but they could just about live with it. That is nonsense. Its NOT engineering spec, its wood that we are dealing with and you should always finish apiece on the bench anyway for final fit if its finer work, if its framing or shuttering it hardly matters if its a touch out, if you cant deal with that with then you wont make a living out of woodworking. Or even get any joy or happiness out of it either, which for me is more the point.

The only aspects of a machine that are really important are the robustness of the whole assembly, the consistency of the squareness of its fencing and blades and blade holding mechanism and that it has the capacity to take the size of work you require it to. The rest is up to operator skill.

In fact most European machines especially those that depend an any substantial castings for their production are manufactured in China......Thats where the foundries are now.

I considered the TS315 until I found it under a different brand and cheaper, and this year will probably buy a Record PT300 planer thicknesser and retire the Scheppach PT.

Its always worth bearing in mind that Record are teamed up with Startrite, who really do have a tradition and know a thing or two about woodworking machines, even though the foundry work is done overseas now..............