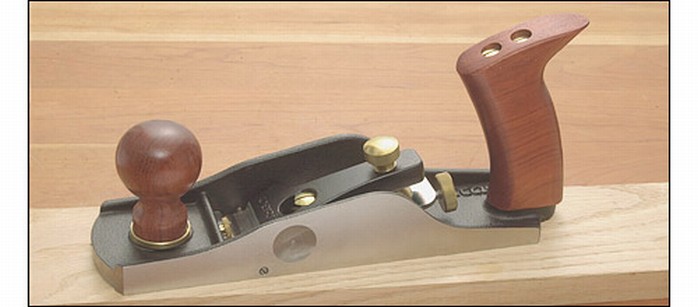

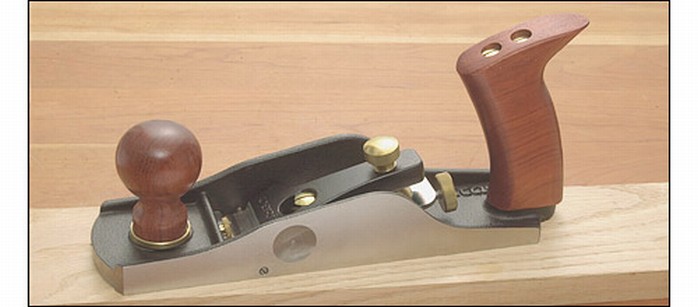

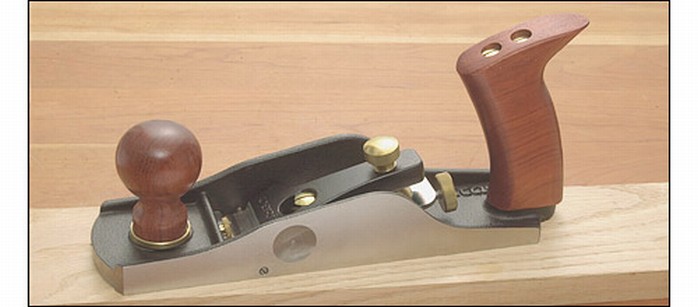

That's a Veritas plane and yes it does have a Norris "style" adjuster including the lateral adjustment which actually does work in their BU range, didn't you own one? The Bailey adjuster is the worst piece of engineering I have ever come across the only good things about it is that eventually it does start to work and it is not life threatening. LN made it better but still far too much slack, at least LV made an effort to improve things.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wooden hand plane advice?

- Thread starter Chris152

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Jacob

What goes around comes around.

I've had both the LN and LV planes with norris (ish) adjusters and neither of them worked (except crudely) you needed a little hammer. Maybe they've improved them?woodbrains":3s4n8eg8 said:Jacob":3s4n8eg8 said:Pretty similar to a norris adjuster here. They have omitted the lateral adjustment part of it which is sensible as it doesn't work. Hence Custard and his little hammer. He'd still need the hammer if it laterally adjusted norris style.

If you want to argue about whether or not it is a Norris adjuster-like then you are missing the point - which is that the standard Stanley bailey design works brilliantly and doesn't need tapping with a hammer.

Hello,

No, that does have the lateral adjustment bit, if you choose to use it. Stanley's version of the Norris adjuster wasn't any good because Stanley made a bloody hash at manufacturing it. Too much slip and lash everywhere. The Veritas one is very good. That said, if you are going to use a woodie, you need to learn hammer adjustment anyway, and once you have it, you can use it where you feel appropriate. I actually prefer hammer adjustment planes to the Bailey adjuster, but use any without complaint, they all work.

Mike.

They did, but the effort made an adjuster that isn't as good and that most people resort to adjusting laterally with a hammer.

An experienced user will find favor with a stanley adjuster, backlash and all, because you can more or less roll through the backlash during the back stroke or while thinking about what you want to do. I used to be bonkers over the LN adjuster because it's slower and tighter, but like the stanley better now (Backlash and all).

I've had, I guess, 10 planes with norris adjusters (half of them norris) and never found one that I really like.

I have had stanley planes i'm not in love with, though, too, because the slot is off center in the iron, necessitating the lateral adjuster to be almost out of travel for the thing to cut straight. It's not a practical problem, but it irritates my eye and brain to see it, because my brain sees it as a plane iron or cap iron ground out of square.

(I wish LN could've made an adjuster that was knurled, though. I can admit that. The look of their adjuster wheel is kind of industrial looking compared to the segmented knurl on stanley planes).

An experienced user will find favor with a stanley adjuster, backlash and all, because you can more or less roll through the backlash during the back stroke or while thinking about what you want to do. I used to be bonkers over the LN adjuster because it's slower and tighter, but like the stanley better now (Backlash and all).

I've had, I guess, 10 planes with norris adjusters (half of them norris) and never found one that I really like.

I have had stanley planes i'm not in love with, though, too, because the slot is off center in the iron, necessitating the lateral adjuster to be almost out of travel for the thing to cut straight. It's not a practical problem, but it irritates my eye and brain to see it, because my brain sees it as a plane iron or cap iron ground out of square.

(I wish LN could've made an adjuster that was knurled, though. I can admit that. The look of their adjuster wheel is kind of industrial looking compared to the segmented knurl on stanley planes).

custard

Established Member

The problem I have with lateral adjusters is when trying to make a minute alteration, say for example during long grain shooting when I need to get the apex of the camber lined up with the dead centre of the workpiece. I can get very close, but that last tiny adjustment is tricky.

I've heard the problem described as "stiction", which captures it very well. When you overcome that initial resistance to movement you suddenly over adjust, so now you need to come back in the other direction. In some cases you can actually feel the pressure building up in the lateral adjustment arm, it feels slightly springy, and then when it does move it moves too far.

The solution I use (and I've seen many others using) is to remove the lateral adjustment arm from the equation, and make the adjustments direct to the iron with small taps.

There's a separate problem I've encountered many times on older Norris planes, when you change the depth of cut the lateral adjustment also changes. I've heard it explained by people far more knowledgeable about Norris planes than I as the result of adjustments being made by previous owners without first slightly slackening the cap iron screw. I don't know if that is correct but it's plausible at least. It's also a tribute to Bailey's engineering genius that he produced a lateral adjustment mechanism that is not only cheaper to manufacture but pretty much immune to this problem.

I've heard the problem described as "stiction", which captures it very well. When you overcome that initial resistance to movement you suddenly over adjust, so now you need to come back in the other direction. In some cases you can actually feel the pressure building up in the lateral adjustment arm, it feels slightly springy, and then when it does move it moves too far.

The solution I use (and I've seen many others using) is to remove the lateral adjustment arm from the equation, and make the adjustments direct to the iron with small taps.

There's a separate problem I've encountered many times on older Norris planes, when you change the depth of cut the lateral adjustment also changes. I've heard it explained by people far more knowledgeable about Norris planes than I as the result of adjustments being made by previous owners without first slightly slackening the cap iron screw. I don't know if that is correct but it's plausible at least. It's also a tribute to Bailey's engineering genius that he produced a lateral adjustment mechanism that is not only cheaper to manufacture but pretty much immune to this problem.

Jacob

What goes around comes around.

The backlash is really useful - you get feedback, you can feel positive engagement - whether the adjuster is in push or pull mode. Even when it's more than a turn it's still OK because with use it moves freely and it's just a flick to spin it all the way.D_W":tsr31ekd said:...

An experienced user will find favor with a stanley adjuster, backlash and all, ....

OK occasionally some of them aren't so good but a properly set up Stanley or Record has the best possible adjuster for both set and lateral adjustment, and easily done with your hand on the handle in mid stroke.

Jacob

What goes around comes around.

But is it cheap to manufacture? Surely it has several more components than the Norris? It's quite elaborate in comparisoncustard":y0v8rfhe said:....It's also a tribute to Bailey's engineering genius that he produced a lateral adjustment mechanism that is not only cheaper to manufacture but pretty much immune to this problem.

£13.99 (£2.80 / count)

VEVOX® FFP1 Dust Mask - Set of 5 - Valved Face Masks - Respirator - Protection e.g. for Construction, Building Work, Sanding, Woodworking, Fine Dusts, Aersoles or Particles

SLSK Ventures GmbH (UK)

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

custard

Established Member

Jacob":3n4vkbxp said:But is it cheap to manufacture? Surely it has several more components than the Norris? It's quite elaborate in comparisoncustard":3n4vkbxp said:....It's also a tribute to Bailey's engineering genius that he produced a lateral adjustment mechanism that is not only cheaper to manufacture but pretty much immune to this problem.

Point taken, I just assumed that as it's a cheap pressing rather than a machined item. But you're right, it could have been a patent issue or some other explanation.

rafezetter

Troll Hunter

Going back to the OP's post - I'd just like to weigh in on the whole "learning to use a woodie is a good thing" advice. I started with metal planes as most do, but having initially bought an old woodie smoother and a jointer several years ago I've come to love them more than my metal planes. So much so I sold my #7 metal jointer and now my woodie collection outnumbers my metal planes 8:4 - not including shoulder and block planes.

Yes they wear but are easily trued up, I don't personally find touching up the thicker blades any more work if you're using micro secondary bevels and the weigh advantage especially on my 22" jointer to be a massive plus.

You can get a wooden plane called a badger which with a bit of alteration can make a very efficient shooting plane, as the blade is set to an angle in the body giving a shear cut, a real advantage against endgrain - I can post a pic if you are interested in how I modified mine.

The biggest breakthrough I found when adjusting by tapping the blade, was that it can take almost nothing to do it, even with a well set wedge, just barely the weight of a small glazing hammer and letting it "freefall" a couple of inches will give you that adjustment you need to get the lateral set as you want it.

Woodies are also great for attaching jigs or other doodad's to, to help with your planing until you can do it without them - training wheels - if you will. I've seen several jointers with wooden side guides to make sure you plane perpendicular to the adjoining face rather than at an angle which will need truing up after and possibly ruining your careful dimensioning to a line. Mostly just a bit of ply screwed onto the body side, and woodies are cheap enough you can make several of these for dedicated tasks.

You could also keep a look out for "transition planes" wooden body to save weight but metal bailey style adjusters to make setting simpler - the best of both.

Edit: one last thing - DO NOT STORE THE PLANE WITH THE WEDGE SET - loosen it off beforehand - apparently this also goes for metal planes too, the pressure over long periods can distort the body. I've not researched this, but I'm sure I read it here and that's good enough for me, so I'm not taking any chances.

Yes they wear but are easily trued up, I don't personally find touching up the thicker blades any more work if you're using micro secondary bevels and the weigh advantage especially on my 22" jointer to be a massive plus.

You can get a wooden plane called a badger which with a bit of alteration can make a very efficient shooting plane, as the blade is set to an angle in the body giving a shear cut, a real advantage against endgrain - I can post a pic if you are interested in how I modified mine.

The biggest breakthrough I found when adjusting by tapping the blade, was that it can take almost nothing to do it, even with a well set wedge, just barely the weight of a small glazing hammer and letting it "freefall" a couple of inches will give you that adjustment you need to get the lateral set as you want it.

Woodies are also great for attaching jigs or other doodad's to, to help with your planing until you can do it without them - training wheels - if you will. I've seen several jointers with wooden side guides to make sure you plane perpendicular to the adjoining face rather than at an angle which will need truing up after and possibly ruining your careful dimensioning to a line. Mostly just a bit of ply screwed onto the body side, and woodies are cheap enough you can make several of these for dedicated tasks.

You could also keep a look out for "transition planes" wooden body to save weight but metal bailey style adjusters to make setting simpler - the best of both.

Edit: one last thing - DO NOT STORE THE PLANE WITH THE WEDGE SET - loosen it off beforehand - apparently this also goes for metal planes too, the pressure over long periods can distort the body. I've not researched this, but I'm sure I read it here and that's good enough for me, so I'm not taking any chances.

bugbear

Established Member

Jacob":3qtoni8a said:Pretty similar to a norris adjuster here. They have omitted the lateral adjustment part of it which is sensible as it doesn't work. Hence Custard and his little hammer. He'd still need the hammer if it laterally adjusted norris style.

If you want to argue about whether or not it is a Norris adjuster-like then you are missing the point - which is that the standard Stanley bailey design works brilliantly and doesn't need tapping with a hammer.

That's just a linear screw adjuster, same as a Stanley block plane, or a Record shoulder plane, or a Stanley spokeshave.

Here's the famously useless 60 1/2 block plane with the same adjuster.

http://www.supertool.com/StanleyBG/stan9.htm#num60.5

BugBear

Jacob

What goes around comes around.

OK. Whatever it is - the point is it needs a little hammer to tilt the blade, as does the full norris pattern. The Stanley pattern doesn't and is, in comparison, a very refined adjustable precision instrument.bugbear":chnsgdoi said:Jacob":chnsgdoi said:Pretty similar to a norris adjuster here. They have omitted the lateral adjustment part of it which is sensible as it doesn't work. Hence Custard and his little hammer. He'd still need the hammer if it laterally adjusted norris style.

If you want to argue about whether or not it is a Norris adjuster-like then you are missing the point - which is that the standard Stanley bailey design works brilliantly and doesn't need tapping with a hammer.

That's just a linear screw adjuster, same as a Stanley block plane, or a Record shoulder plane, or a Stanley spokeshave.

BugBear

A lot of it is down to first impressions - the norris thing looks neat and clever and how it is supposed to work is obvious, but it doesn't work very well. The Stanley looks a bit fussy with more bits and it's not obvious why they are necessary - until you realise that it works very well.

bugbear

Established Member

Jacob":mhjxjqqs said:Old Stanley 220 my favourite and this is the one essential plane for finishing/fitting ...

BugBear

Attachments

Jacob

What goes around comes around.

You are missing the point - as usual!

I'm flattered that you have such a detailed recollection of everything I write!

I'm flattered that you have such a detailed recollection of everything I write!

iNewbie

Established Member

For a moment there I thought you were going to laterally; I mean literally, tap him with a hammer. :mrgreen:

Never used an infill with an adjuster so no comment. Just imagine years from now all those LV planes that have been battered with hammers when all you need to do is not tighten the lock cap screw too much probably the same as those abused infills. Having said that I do prefer the Bailey lateral adjuster especially when the lever is reasonably near center.

Just a note for Chris, if you are still reading this.

Please don't be dismayed by the way your question about wooden planes has veered off into a discussion about the adjusters on metal planes or wonder if it's because of the way you asked the question.

It's a common pattern for discussions round here. Sometimes it's just the old hobbyhorses being taken for a canter round the paddock, sometimes some useful information finds its way into the mix.

I'm hoping someone will chip in soon to explain dovetails, or the last hundred years of furniture design. ](*,)

Please don't be dismayed by the way your question about wooden planes has veered off into a discussion about the adjusters on metal planes or wonder if it's because of the way you asked the question.

It's a common pattern for discussions round here. Sometimes it's just the old hobbyhorses being taken for a canter round the paddock, sometimes some useful information finds its way into the mix.

I'm hoping someone will chip in soon to explain dovetails, or the last hundred years of furniture design. ](*,)

bugbear":3ogh4zt9 said:View attachment 220Jacob":3ogh4zt9 said:Old Stanley 220 my favourite and this is the one essential plane for finishing/fitting ...

BugBear

220, 221, whatever it takes.

( for anyone who has ever seen Mr mom).

Chris152

Established Member

It's brilliant - lots of advice on the wooden plane and lots more besides - can't pretend I understand it all, but more than happy to read!AndyT":3uudidlc said:Just a note for Chris, if you are still reading this.

Please don't be dismayed by the way your question about wooden planes has veered off into a discussion about the adjusters on metal planes or wonder if it's because of the way you asked the question.

It's a common pattern for discussions round here. Sometimes it's just the old hobbyhorses being taken for a canter round the paddock, sometimes some useful information finds its way into the mix.

I'm hoping someone will chip in soon to explain dovetails, or the last hundred years of furniture design. ](*,)

rafezetter

Troll Hunter

I did try to steer it back on course but Jacob and bugbear do like their regular "debates" and never let anything like derailing a thread get in thier way....

Jacob

What goes around comes around.

:lol:rafezetter":ryw1zr04 said:I did try to steer it back on course but Jacob and bugbear do like their regular "debates" and never let anything like derailing a thread get in their way....

No it was sent off by Custard suggesting that all planes need a hammer for lateral adjustment. I was arguing that Stanley/Bailey pattern don't, which is on topic as it's a big advantage over woodies (and Norris style adjustables).

iNewbie

Established Member

Jacob":2ic5im5l said::lol:rafezetter":2ic5im5l said:I did try to steer it back on course but Jacob and bugbear do like their regular "debates" and never let anything like derailing a thread get in their way....

No it was sent off by Custard suggesting that all planes need a hammer for lateral adjustment. I was arguing that Stanley/Bailey pattern don't, which is on topic as it's a big advantage over woodies (and Norris style adjustables).

Now now, don't misquote the fella. This is what he wrote:

"A reasonable question to ask might be, "if wooden jacks are so good then why doesn't everyone use one?"

-they're rubbish for planing down the edges of plywood. The glass hard UF glue used in ply will wear a groove along the sole of a wooden plane in no time. When plywood started to become widely used after the 2nd World War it effectively spelt the end for the wooden jack

-they also wear out faster than a metal plane, in particular you'll often find a small hollow worn into the sole immediately in front of the mouth. The remedy is a patch of harder wood let in and smoothed down, but few people have the skill or patience to do that

-DIY-ers want instant results, so investing the time to learn how to set up and adjust a wooden plane isn't for them

-making the lateral adjustment with hammer taps is often thought of as clumsy and inefficient, that's a bit weird as even on the most expensive Lie Nielsen or Norris I find the lateral adjustment is only good for rough approximate settings, to make a tiny precise lateral adjustment on any plane you'll find experienced woodworkers generally use a light tap from a small hammer, chisel handle, or whatever else is lying on the bench"