custard

Established Member

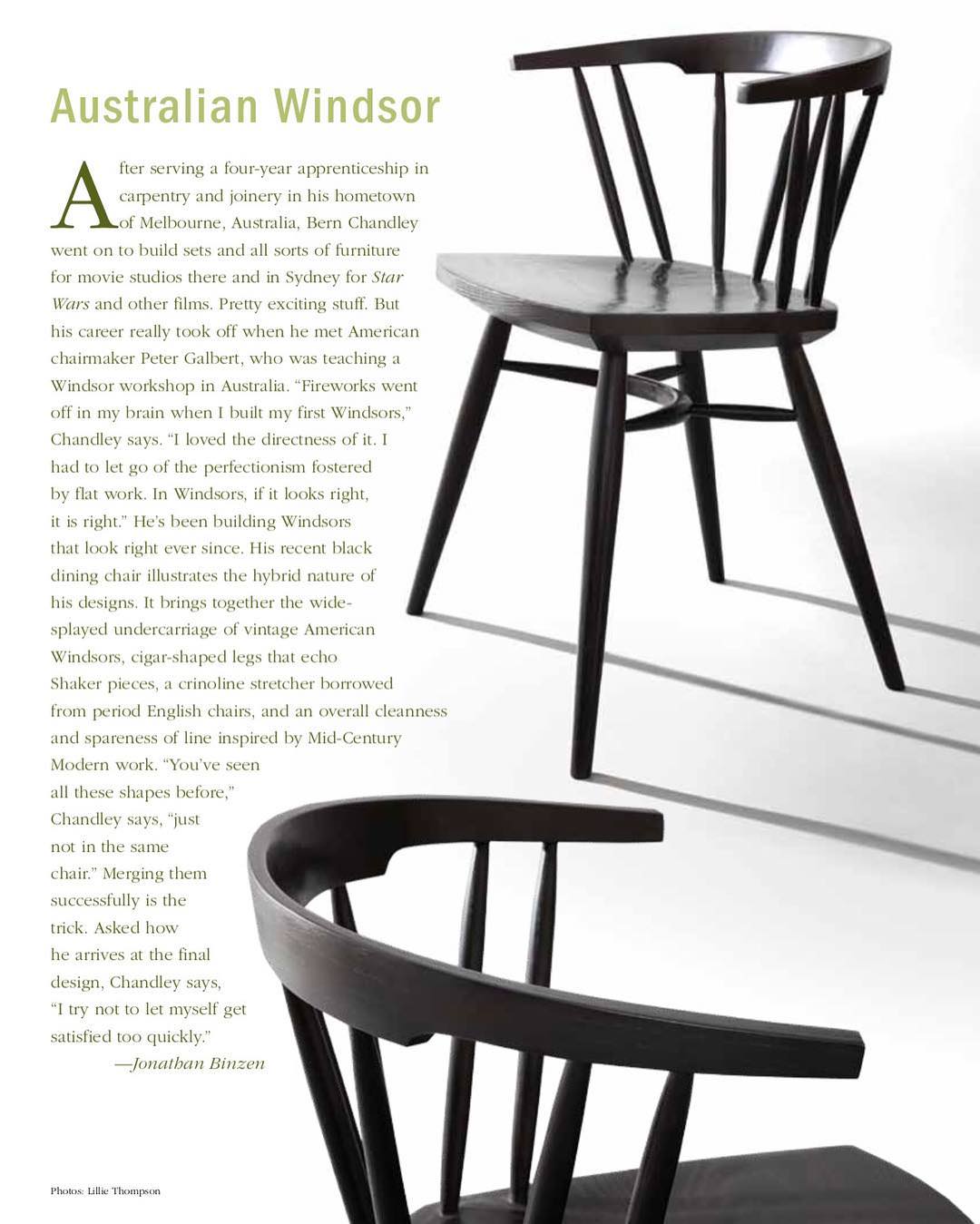

There's been quite a lot of mention on the forum recently about windsor chairs, and that interest is currently being echoed elsewhere.

This month's edition of Furniture & Cabinetmaker features a detailed look at the building of a very contemporary version of a windsor,

It's a smashing article, giving full measured plans plus detailed constructional advice on how it was made. It was interesting to see just how many bang on-trend design details were incorporated into this build, the seat is textured with thousands of gouge cut dimples, there's no turning as all the legs and spindles are octagonal in cross section, the finish is paint plus Osmo 3044 to give that bone white, bleached driftwood type effect, and the aggressive curve to the crest rail was achieved by "bricking" together individual overlapping blocks rather than laminating or steam bending.

Moving to the other end of the windsor chair age spectrum an interesting article appeared a few days ago on Pegs & Tails, a fascinating blog that Andy T alerted me to,

https://pegsandtails.wordpress.com

The Pegs & Tails article shows the kind of luscious patination that Elm develops after a few hundred years of waxing, oxidation, and bottom burnishing! Sadly English Elm is virtually unobtainable these days. I was active as windsor chair maker when Dutch Elm disease first struck, and the market was flooded with vast quantities of Elm boards at absolutely give away prices. I've still got a few, whopping boards nearly a metre across and 65mm thick, in case the windsor chair spirit moves me again,

El Barto of this forum recently completed a week long training course in windsor chair making and posted an excellent write up, given that he's clearly got the bug I dug out a thick English Elm blank for him, so he can make a windsor seat out of a single Elm board in the traditional way,

If you're tempted to follow then you should be aware that a number of the Scottish timber yards occasionally have thick boards of Wych Elm that's eminently suited for windsor seat making. They generally max out at 50mm or 55mm thick, so a whisker less than the ideal 65mm, but still perfectly serviceable. This is a typical Wych Elm board that I picked up from one of the yards in the Dunkeld area, it has a redder tone and typically greater amounts of pippy figure, as you can see this one is marked up for three chair seat blanks, which is a fairly typical yield

You'll still occasionally find some astonishing Wych Elm boards, this was a corker that I found for a waney edge table,

In close up it showed the most mesmerising grain and figure,

In a sense were fortunate in this country that there are no longer any UK veneer mills, it means that solid boards like this nearly always make there way to the market instead of being sliced into veneers.

This month's edition of Furniture & Cabinetmaker features a detailed look at the building of a very contemporary version of a windsor,

It's a smashing article, giving full measured plans plus detailed constructional advice on how it was made. It was interesting to see just how many bang on-trend design details were incorporated into this build, the seat is textured with thousands of gouge cut dimples, there's no turning as all the legs and spindles are octagonal in cross section, the finish is paint plus Osmo 3044 to give that bone white, bleached driftwood type effect, and the aggressive curve to the crest rail was achieved by "bricking" together individual overlapping blocks rather than laminating or steam bending.

Moving to the other end of the windsor chair age spectrum an interesting article appeared a few days ago on Pegs & Tails, a fascinating blog that Andy T alerted me to,

https://pegsandtails.wordpress.com

The Pegs & Tails article shows the kind of luscious patination that Elm develops after a few hundred years of waxing, oxidation, and bottom burnishing! Sadly English Elm is virtually unobtainable these days. I was active as windsor chair maker when Dutch Elm disease first struck, and the market was flooded with vast quantities of Elm boards at absolutely give away prices. I've still got a few, whopping boards nearly a metre across and 65mm thick, in case the windsor chair spirit moves me again,

El Barto of this forum recently completed a week long training course in windsor chair making and posted an excellent write up, given that he's clearly got the bug I dug out a thick English Elm blank for him, so he can make a windsor seat out of a single Elm board in the traditional way,

If you're tempted to follow then you should be aware that a number of the Scottish timber yards occasionally have thick boards of Wych Elm that's eminently suited for windsor seat making. They generally max out at 50mm or 55mm thick, so a whisker less than the ideal 65mm, but still perfectly serviceable. This is a typical Wych Elm board that I picked up from one of the yards in the Dunkeld area, it has a redder tone and typically greater amounts of pippy figure, as you can see this one is marked up for three chair seat blanks, which is a fairly typical yield

You'll still occasionally find some astonishing Wych Elm boards, this was a corker that I found for a waney edge table,

In close up it showed the most mesmerising grain and figure,

In a sense were fortunate in this country that there are no longer any UK veneer mills, it means that solid boards like this nearly always make there way to the market instead of being sliced into veneers.