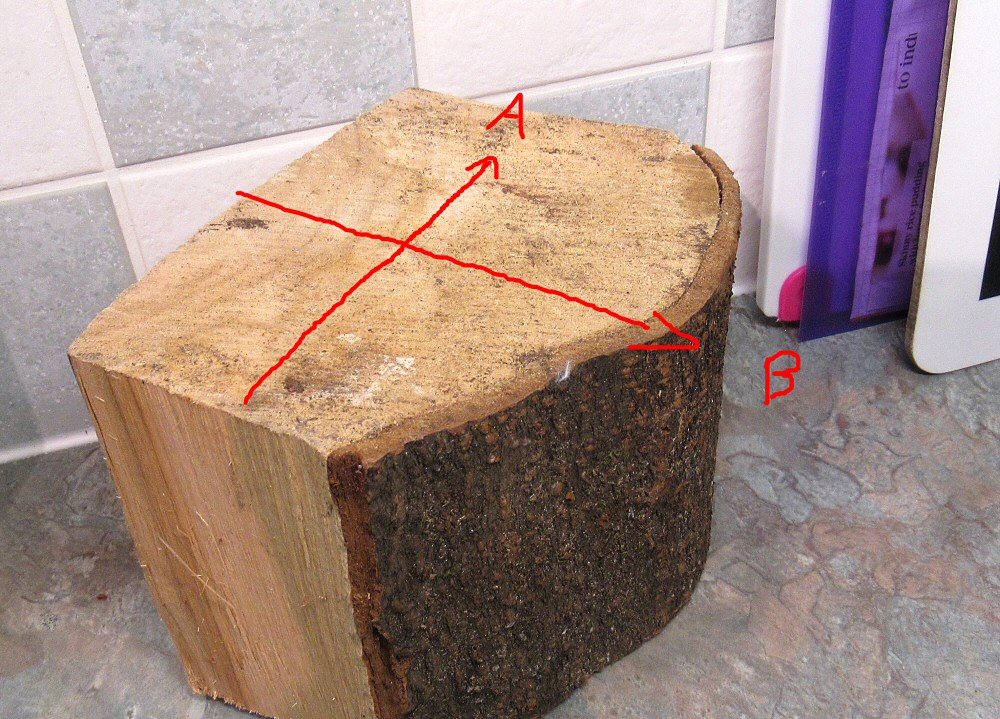

Two Questions

Anyone identify this wood, when cut it looks orange, however I guess it will revert to that dark colour on the uncut bit after a month or two. For contrast I layed it upon a bit of Walnut inlayed into some pine. (just wanted to show off my inlay - LOL)

And second question -

I am wanting to take some 2mm strips from this bit of Cherry for inlaying purposes , Which direction would be the best to cut it , A or B ?

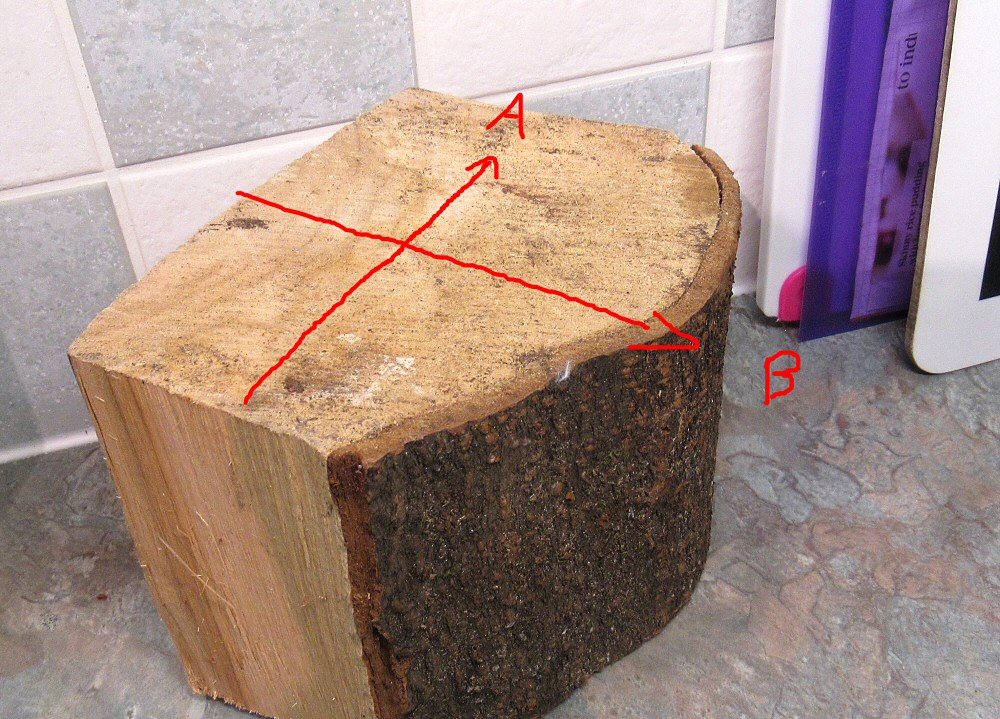

Anyone identify this wood, when cut it looks orange, however I guess it will revert to that dark colour on the uncut bit after a month or two. For contrast I layed it upon a bit of Walnut inlayed into some pine. (just wanted to show off my inlay - LOL)

And second question -

I am wanting to take some 2mm strips from this bit of Cherry for inlaying purposes , Which direction would be the best to cut it , A or B ?