It looks like a Wadkin RA (or RAA) 6in overhand planer (as opposed to a panel planer, aka a thicknesser), but it almost looks as though somebody has been messing about with it. The factory normally supplied these machines with the motor mounted onto a frame at the front/rear of the main base casting (see below) or sometimes on a cradle inside the main base. Yours appears to have the motor mounted directly to the end of the cutterblock, which on an induction motor on standard mains power (50Hz) would give at best only 3000 rpm (as opposed to the 4500 to 6000 rpm afforded by a 4-pole motor 3:1 or 4:1 pulley ratio). It may be, however, that the factory did supply this machine with a 3-cutter block (most were 2-cutter blocks) to compensate for the low block speed, but I can't see the smoothness of cut being any better trhan a standard machine (in fact it's possibly a lot worse). Another possibility is that the motor is a DC motor, or possibly one designed to run on what would nowadays be a non-standard frequency (quite common before the National Grid of the 1930s) on which it might well run at the correct speed of 5000 rpm. There's even the possibility that the machine has a slip ring motor capable of running at 5000 rpm on standard 50Hz power. wadkin did fit these onto a number of machines in the late 1920s although it was mainly spindle moulders. The machine is very old because its' plate states the manufacturer name "Wadkin & Co". Wadkin became a limited company in 1931 so your machine is at least 77 years old as it pre-dates the formation of the limited company.

As to what needs looking at I'd suggest starting be removing the rear fence, then both of the tables to allow you to examine the gibs and ways (what the table slides on) before looking at the state of the ball bearings on the ends of the cutter blocks. the main things wrong with the machine appear to be that it has no crown guard (although it does still have the bracket) and it is missing a DoL starter. As to converting the machine to single phase I'd consider taking the motor off and replacing it with a pulley. The whole affair can then be powered with an off-the shelf single-phase motor mounted underneath on the floor and driving via a v-belt with a ratio of 1:3.33 if you want to reproduce the stated 5000 rpm from a 4-pole (1500 rpm) motor, o 1:1.66 for a 2-pole (2#3000 rpm) motor. Do remember to guard the belt.

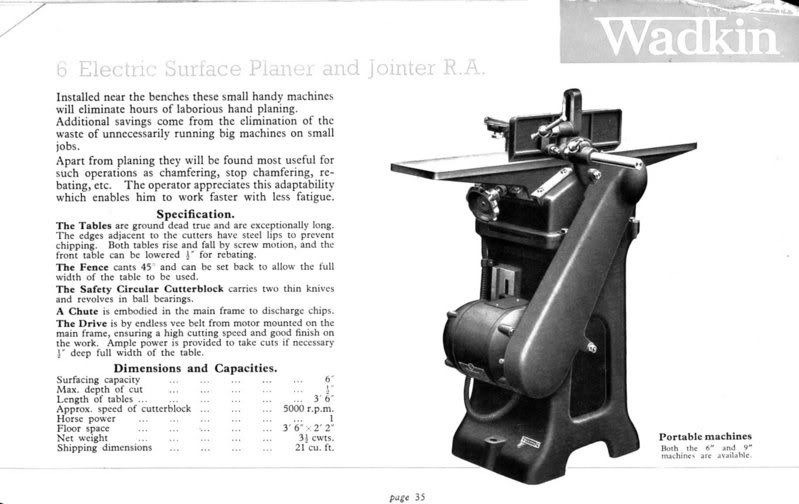

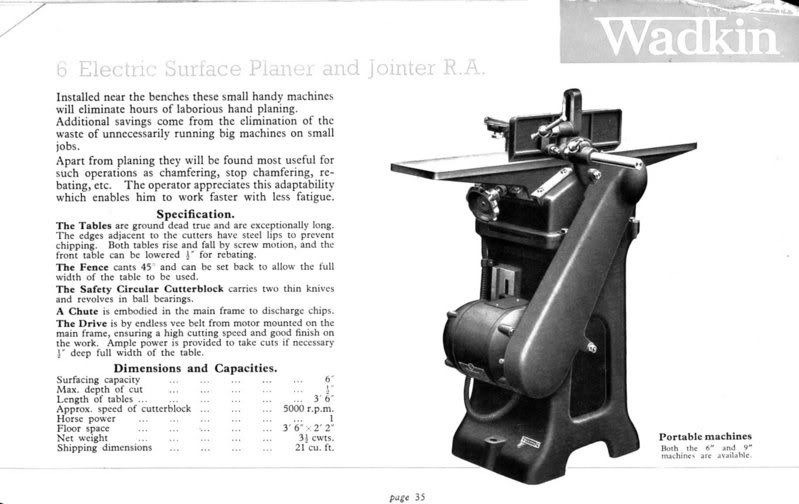

To give you an idea of what the machine looked like when newer, here's a 1949 Wadkin catalogue page:

Before you ask the machine would originally have been painted daek grey or black - but be careful of the original paint as it is a lead-based finish

Scrit

As to what needs looking at I'd suggest starting be removing the rear fence, then both of the tables to allow you to examine the gibs and ways (what the table slides on) before looking at the state of the ball bearings on the ends of the cutter blocks. the main things wrong with the machine appear to be that it has no crown guard (although it does still have the bracket) and it is missing a DoL starter. As to converting the machine to single phase I'd consider taking the motor off and replacing it with a pulley. The whole affair can then be powered with an off-the shelf single-phase motor mounted underneath on the floor and driving via a v-belt with a ratio of 1:3.33 if you want to reproduce the stated 5000 rpm from a 4-pole (1500 rpm) motor, o 1:1.66 for a 2-pole (2#3000 rpm) motor. Do remember to guard the belt.

To give you an idea of what the machine looked like when newer, here's a 1949 Wadkin catalogue page:

Before you ask the machine would originally have been painted daek grey or black - but be careful of the original paint as it is a lead-based finish

Scrit