wallace

Established Member

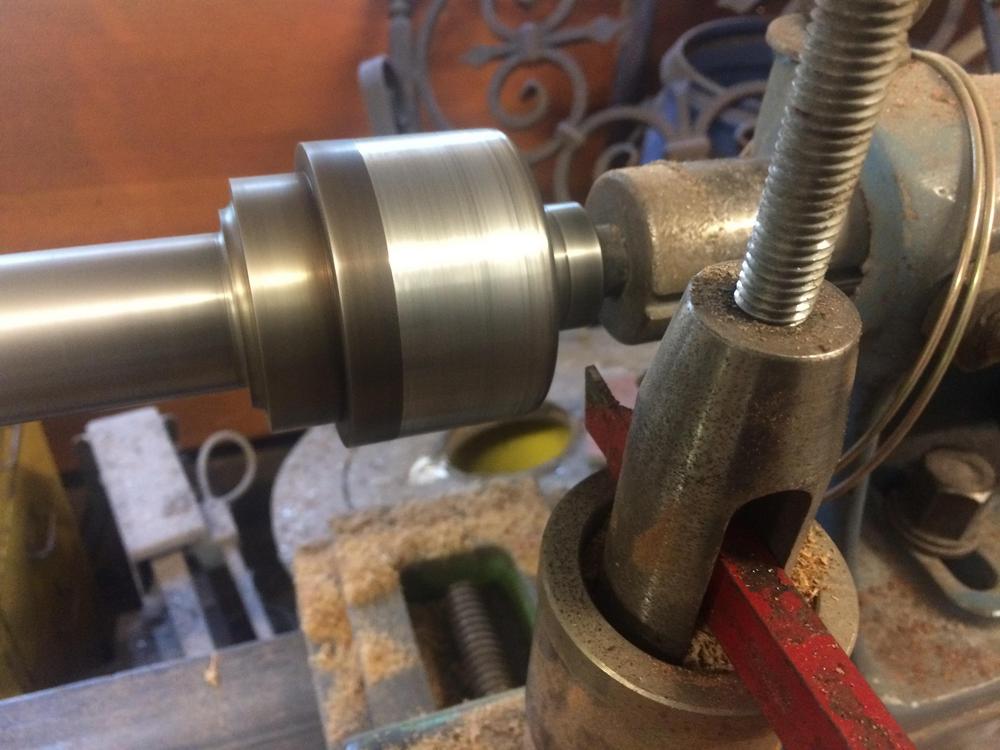

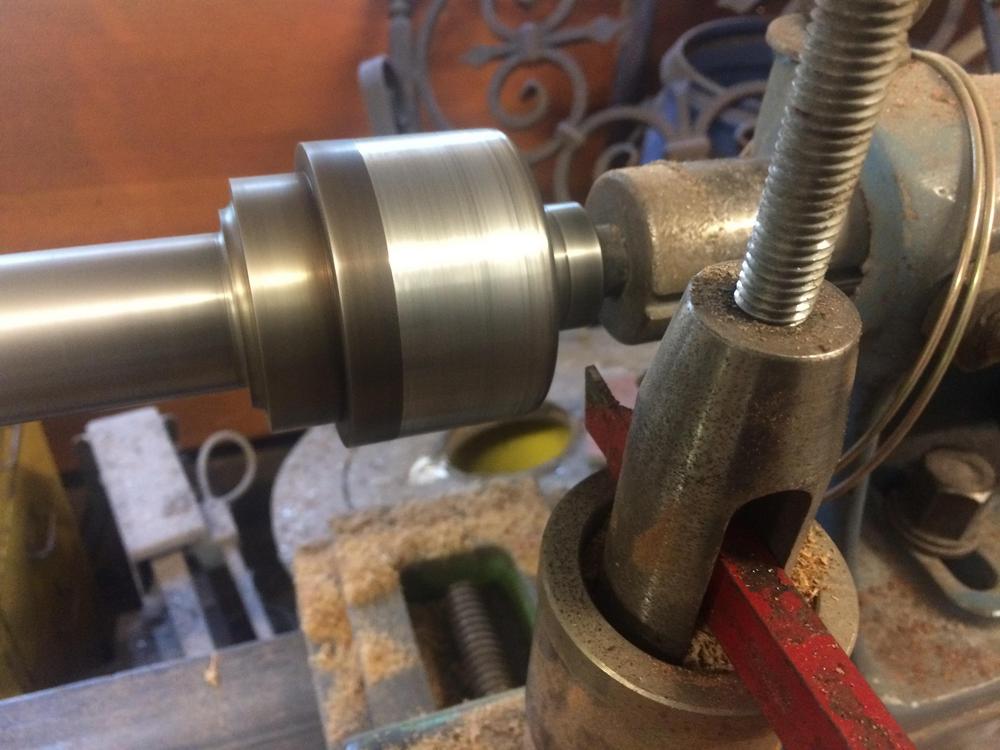

There are times when you just have to give up and give the item o the big boys to sought out. After god knows how many hours I spent trying to get the adapter out of the spindle, I took it to a local engineering place. They put it in a lathe and bored it out. They said it still wouldn't come out until there was a thin sliver left. The best £20 I ever spent, I wish I'd done it weeks ago and saved 15hrs of trying to get it out.

The surface had suffered a bit with my attempts at removing the adapter so I put in in the lathe and gave it a skim.

The keyless chuck came out nice after a night in evaporust and a wire wheel

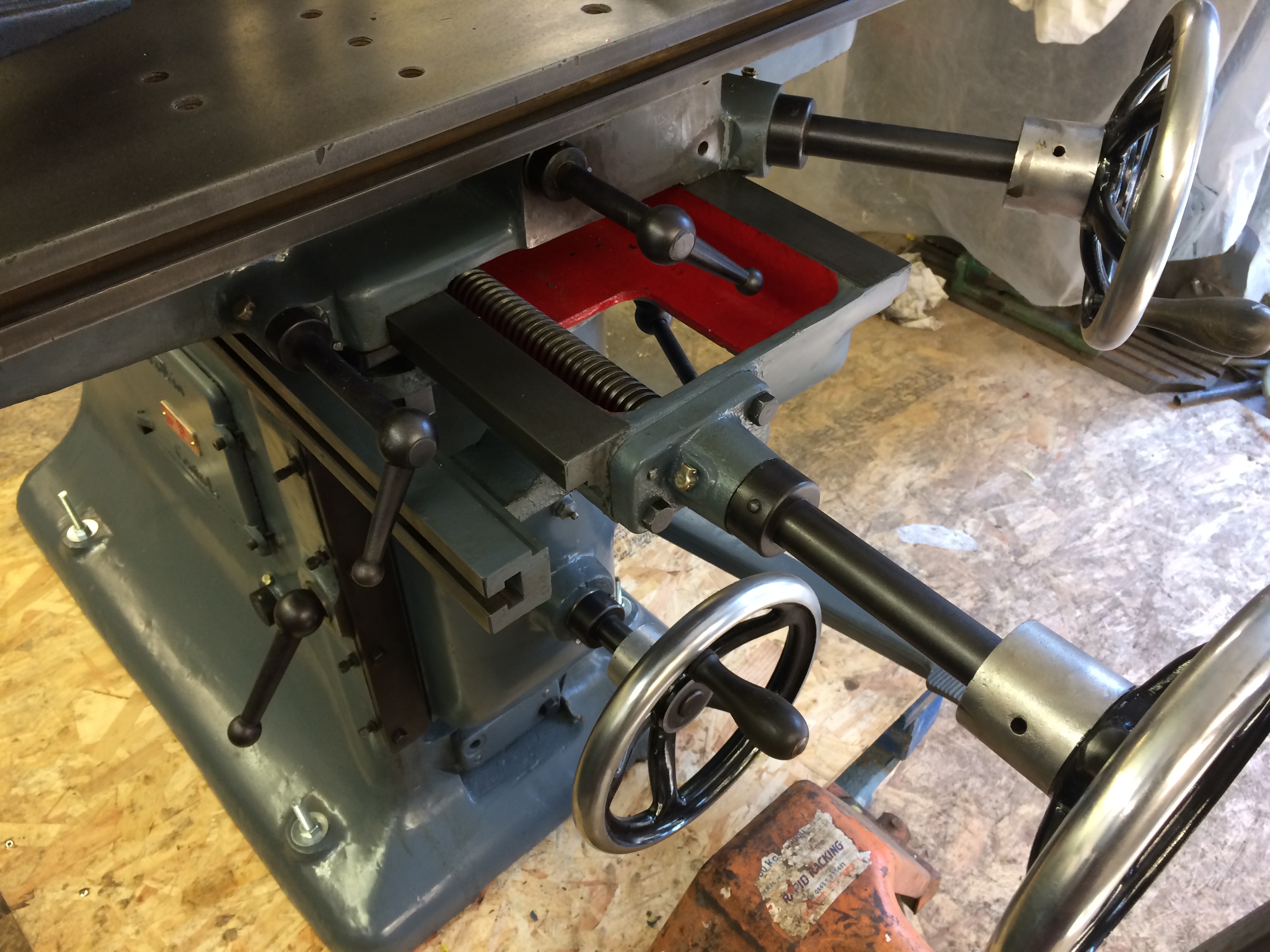

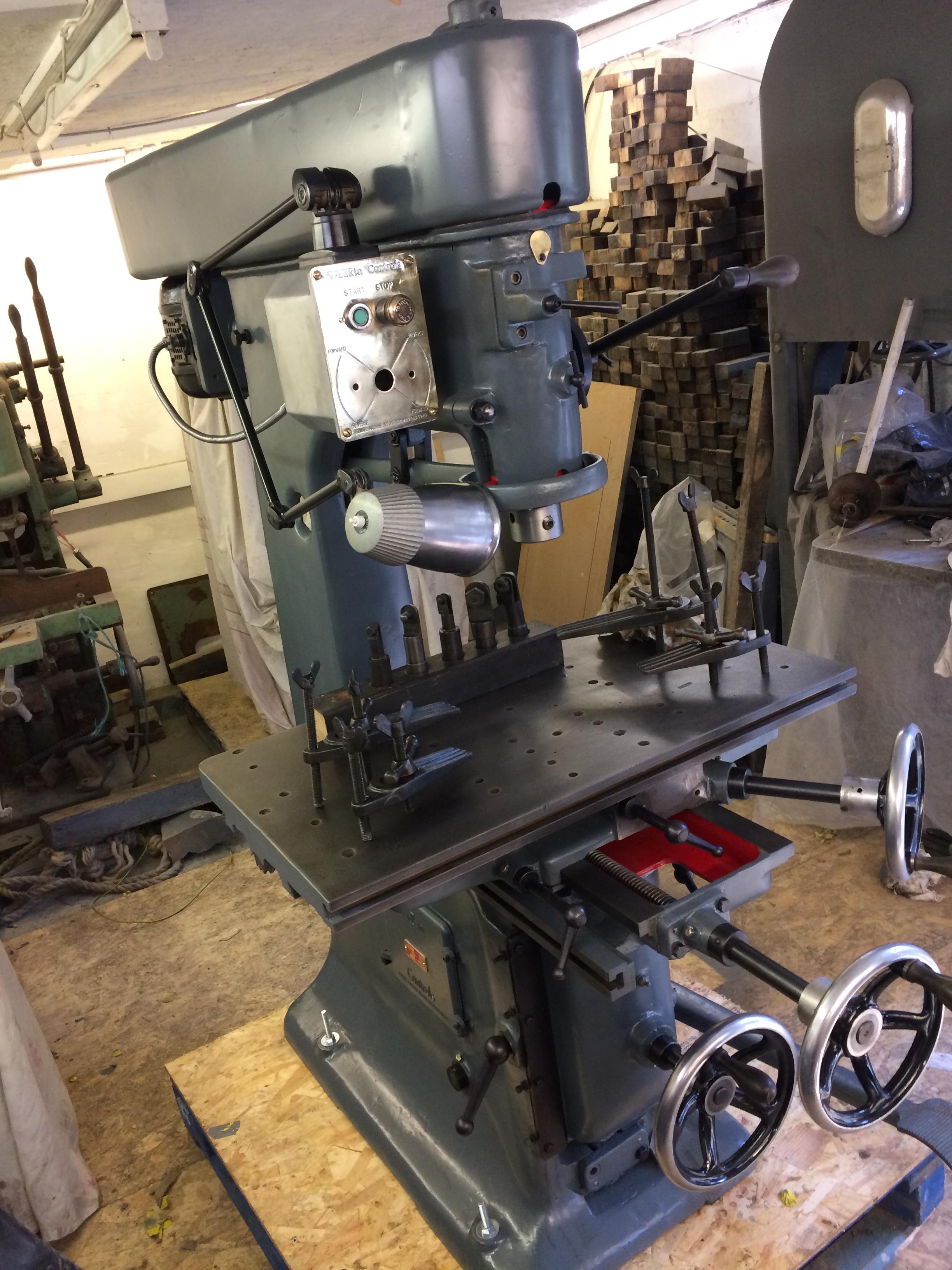

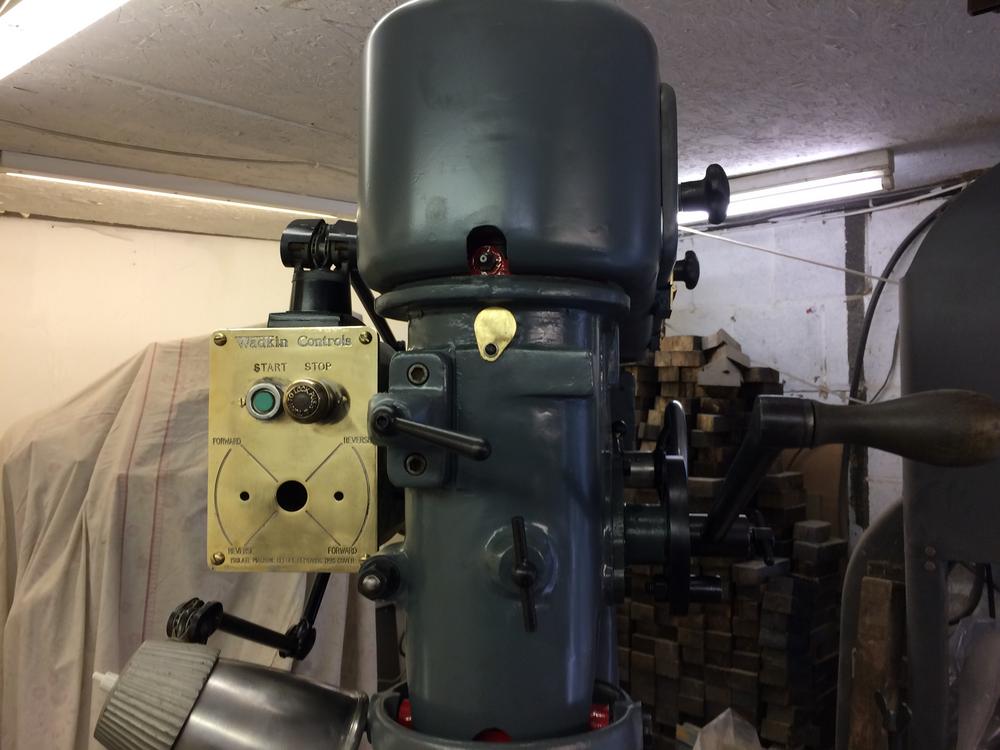

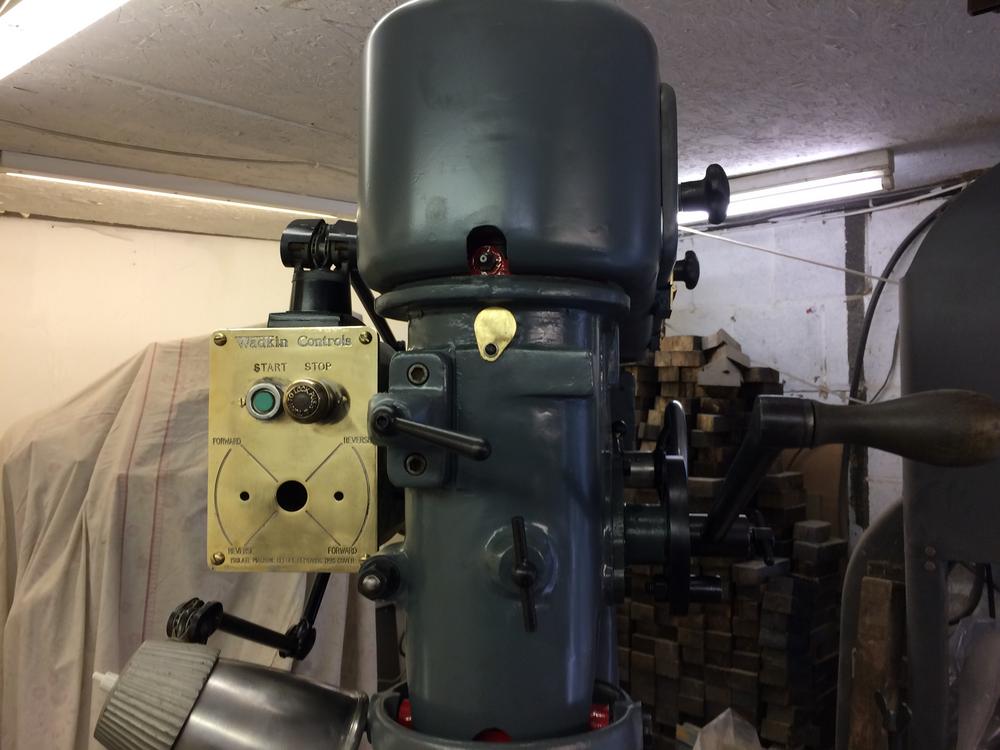

The head was fun putting back onto the main casting

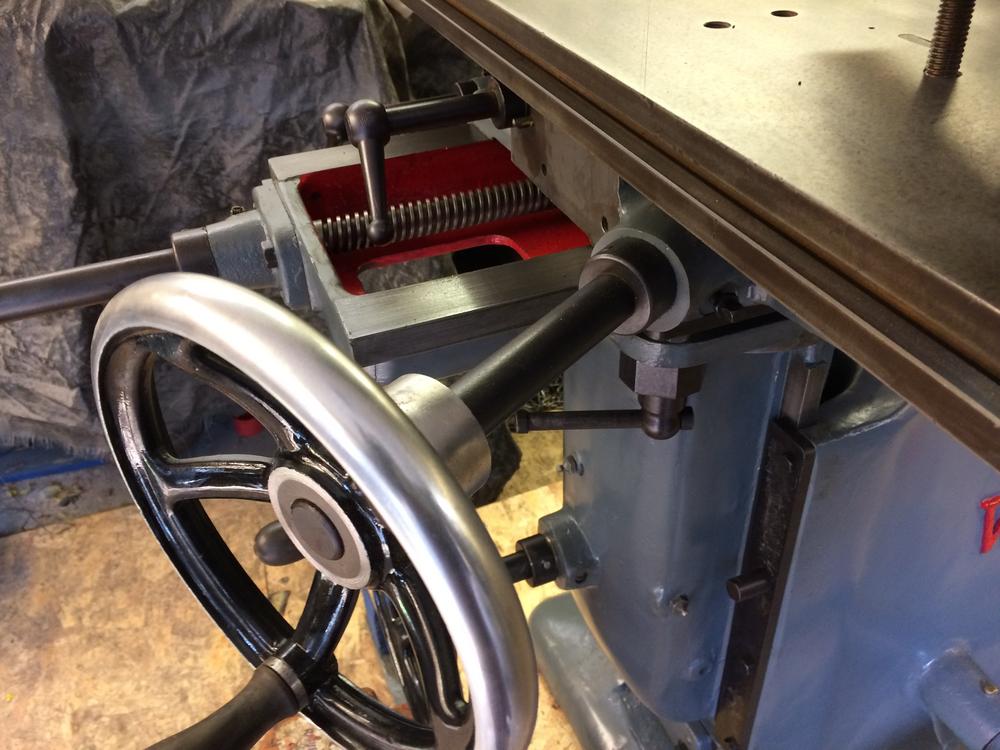

The spindle assembly was a bit easier, I used the table to lift it into the housing

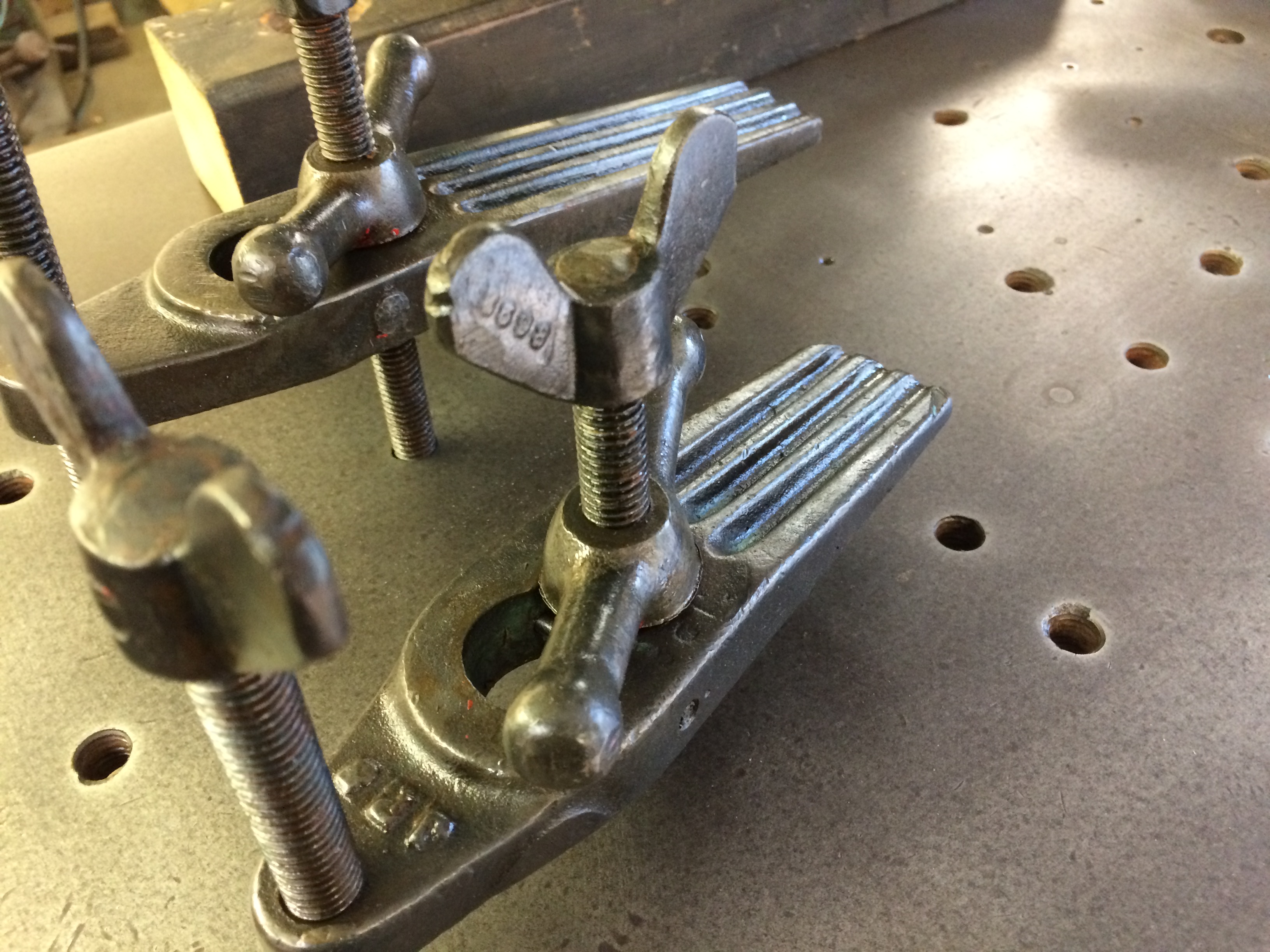

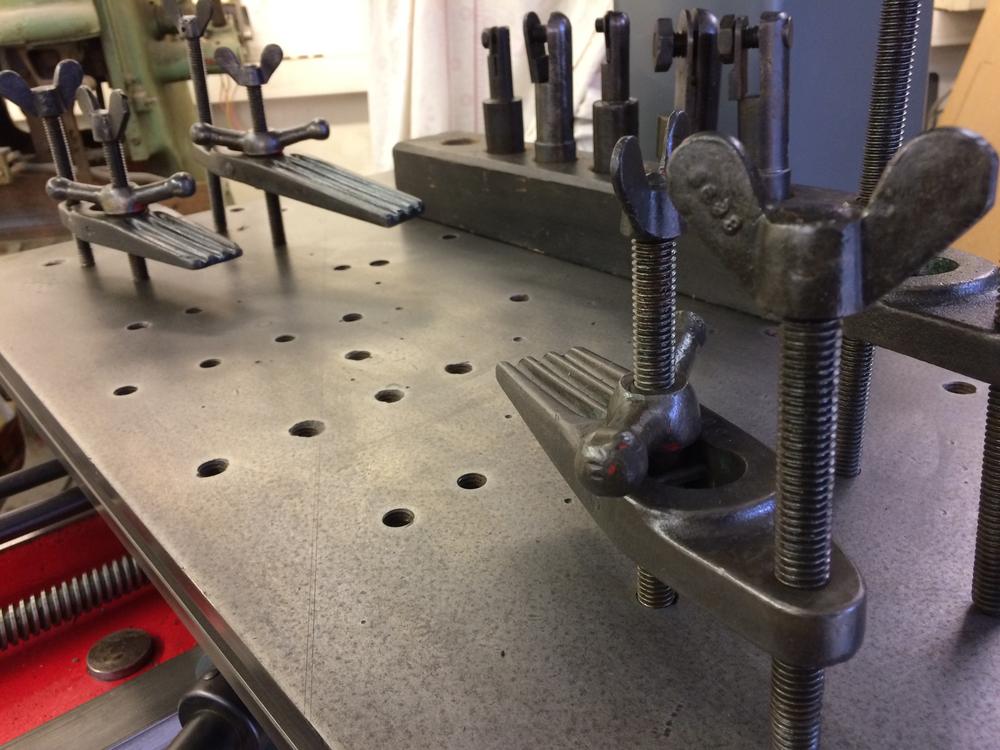

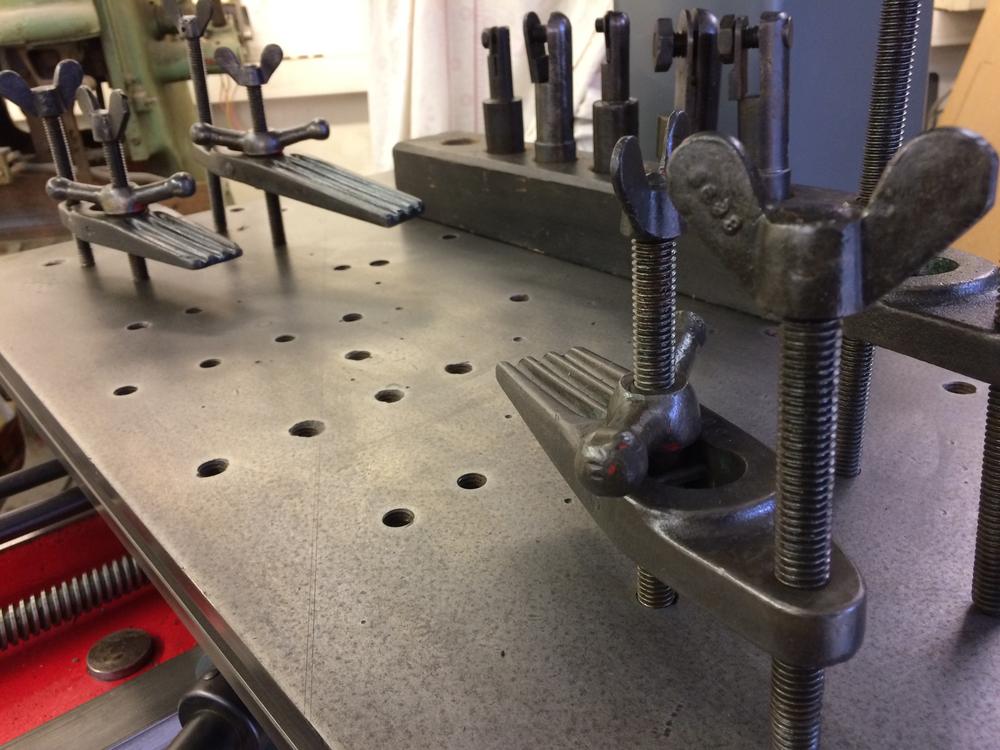

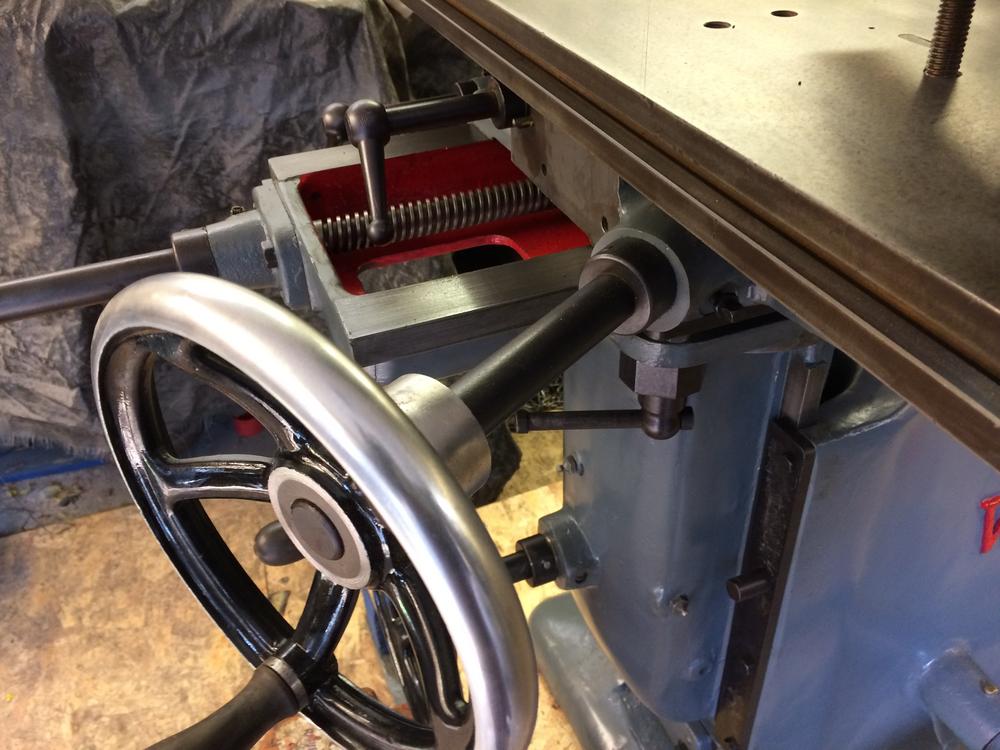

The hold downs were blackened with frosts blackening solution

Im quite liking the blackened look

A little update on mamma blackbird, 3 chicks hatched this morning

The surface had suffered a bit with my attempts at removing the adapter so I put in in the lathe and gave it a skim.

The keyless chuck came out nice after a night in evaporust and a wire wheel

The head was fun putting back onto the main casting

The spindle assembly was a bit easier, I used the table to lift it into the housing

The hold downs were blackened with frosts blackening solution

Im quite liking the blackened look

A little update on mamma blackbird, 3 chicks hatched this morning