wallace

Established Member

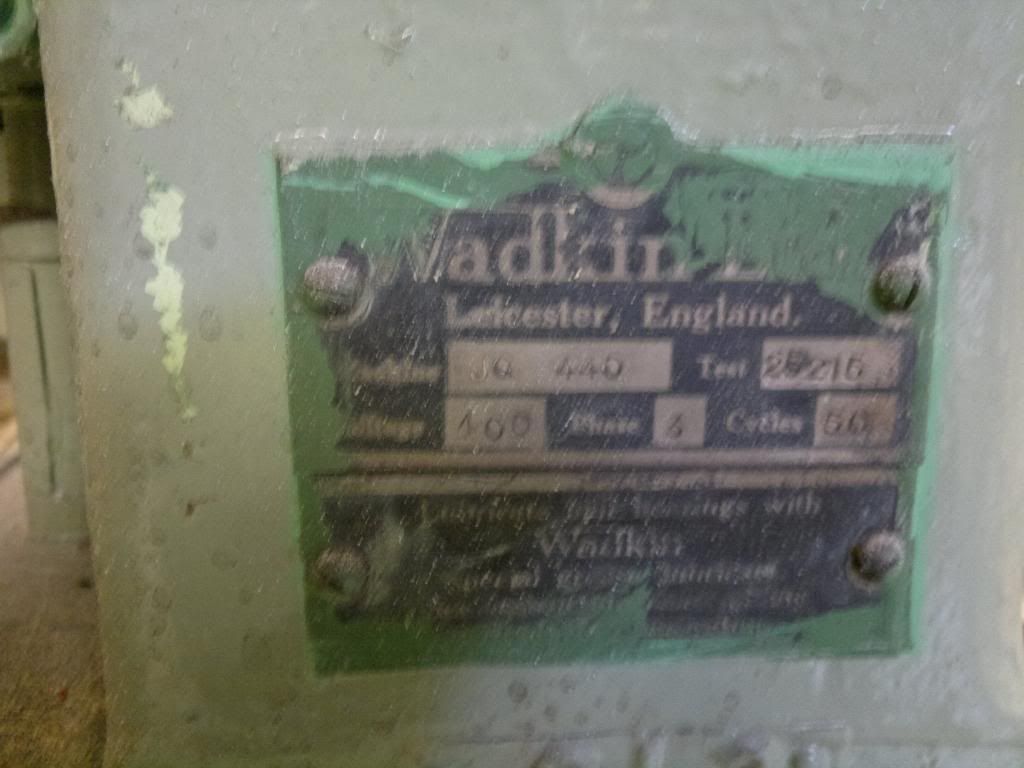

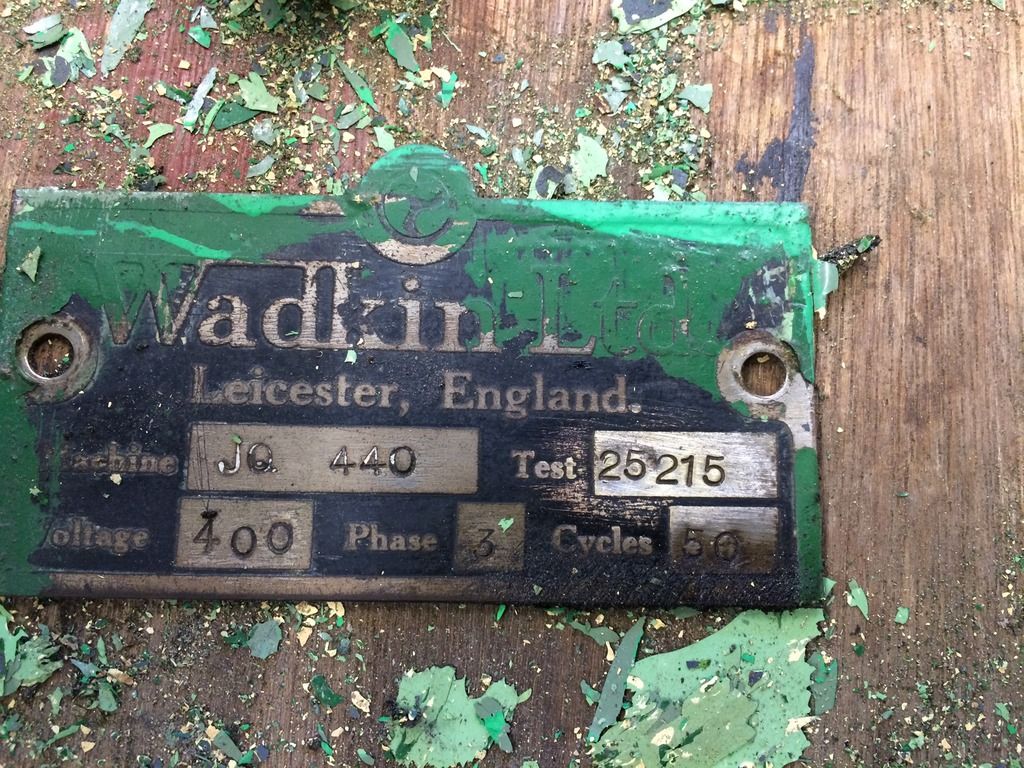

I've had a change of mind and decided to do this little sander instead of the LQ. I'm going to leave the LQ smeared in plus gas for a while. I got this from a foundry pattern shop in Bolton that was closing. I've had it a couple of years and its a lovely thing.

When I started stripping it I noticed it still has a lot of original wiring which is well past its best, the cloth was starting to drop to bits so its probably a good thing I chose this one.

When I started stripping it I noticed it still has a lot of original wiring which is well past its best, the cloth was starting to drop to bits so its probably a good thing I chose this one.