BMac

Established Member

LOL, too many 'Mikes', we'll have to give you numbers.

Brendan

Brendan

So here's a pile of materials, some ply, wheels and hardboard:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2985.jpg[/img]

Cutting pieces to size with circular saw and homemade guide rail:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2986.jpg[/img]

Boards cut to size:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2987.jpg[/img]

Test fit and sinking some holes:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2988.jpg[/img]

Some silicone in the joints to make it air tight:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2989.jpg[/img]

Once I'd screwed together I got silicone squeeze out all along the joints - hopefully means they're airtight!:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2990.jpg[/img]

Cutting the hole in the top 'shelf':

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2991.jpg[/img]

Top 'shelf' fitted:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2992.jpg[/img]

Lower baffle installed:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2993.jpg[/img]

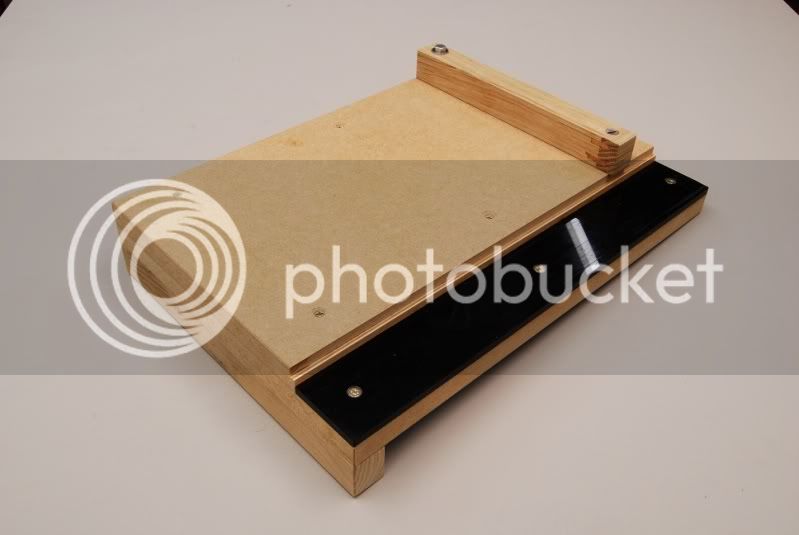

Batons and hardboard screwed and drilled in place:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2994.jpg[/img]

Progress so far:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2995.jpg[/img][img]http://www.mikesaville.co.uk/images/woodwork/IMG_2997.jpg[/img]

Drilling holes in the upper baffle:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2998.jpg[/img]

Front siliconed and ready to go on:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_2999.jpg[/img]

A solid box:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3000.jpg[/img]

Using the guide rail to cut the top off the box:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3001.jpg[/img]

In two halves, a lid and the base/bin:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3002.jpg[/img]

As luck would have it the door seal I had left over from our front door appears to be exactly 18mm wide, perfect :D :

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3005.jpg[/img]

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3006.jpg[/img]

Catches installed to lock two halves together:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3008.jpg[/img]

Castors attached:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3009.jpg[/img]

Vac attached. I simply screwed through the base into the top of my box:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3010.jpg[/img]

Vac on top and intake hose cut to length:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3011.jpg[/img]

Plenty of hot melt glue to attach hose through hole in top of box:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3012.jpg[/img]

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3013.jpg[/img]

Hole drilled in side for main hose to tools:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3014.jpg[/img]

More hot glue and hose attached to side:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3015.jpg[/img]

Completed:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3016.jpg[/img]

In it's new home:

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3018.jpg[/img]

Finally a first test. It works!!! Shavings in the box and not the bag :D

[img]http://www.mikesaville.co.uk/images/woodwork/IMG_3017.jpg[/img]

Mike.C":f4bm5c4k said:How did Mike (Saville) decide where to put the baffle's and how many to use? What are the baffle's for?

How did any of you decide what size box to build?

I have 100mm metal extraction piping around my workshop, but I am very unsatisfied with its performance. Would one of Mike Garnham's box's work with a 100mm system? and if so how big would the box need to be?

Mike.C":3t2vi737 said:How did Mike (Saville) decide where to put the baffle's and how many to use?

Mike Garnham":23gyvxxp said:Mike.C":23gyvxxp said:How did Mike (Saville) decide where to put the baffle's and how many to use? What are the baffle's for?

How did any of you decide what size box to build?

I have 100mm metal extraction piping around my workshop, but I am very unsatisfied with its performance. Would one of Mike Garnham's box's work with a 100mm system? and if so how big would the box need to be?

Mike,

It should work really well with your system, I'd have thought. The thing is, it can be made of scrap in a few hours for zero cost, so if it doesn't work there is no harm done.

My instinct is that your hose cross sectional area is approx. 9 times mine, so the volume in the box should be roughly 9 times the volume of my box......and the dims of mine are above (page 3). The volume of my current box is .08 cu.m roughly, so I reckon yours should be at least three quarters of a cubic metre.......but the bigger it is, the better it will work.

The baffles are there merely to knock some of the sawust and chips out of the airstream so that gravity can grab them more easily.

The other thing that would make it better, I think, would be if the drop-box was located adjacent to the machine, .....but this probably isn't too important.

The only other thought I have had about your set-up with multiple machines trying to work together to do the extracting, is are they working with each other, or cancelling each other out?

What you are proposing is exactly what I have in mind when I build my next workshop.

Mike

The positioning of that main vertical baffle also occurred to me as soon as I'd fixed it in place. No problem, as everything is just screwed together internally so tomorrow I'll take all the gubbins out the middle and reposition that baffle a lot closer to the input portMike Garnham":230l9rvv said:Looks good Rob. Are you planning on a see-through door, or are you going to do a solid one? The vertical baffle in the main chamber is one you might end up adjusting, maybe. The closer to the inlet hose that it is the more abrupt the shock for the shavings rushing in, and the more likely they are to fall unconscious on the floor.........you get my drift!

Mike

What skip is that and where is it? I've never seen anything like that in a skip and I can't resist a quick peek into any one I happen to pass.woodsworth":3kt4qgb3 said:Wouldn't it be easier to recycle one of the thousands of cyclone's tossed away at the skip?