Nothing wrong with that Benny. Looks like a great working bench. Fair play.

Was wondering about this the other day, began cutting/drilling the mortices out on the underside today on mine and pondering the final height. The solution I came up with was just two extra leg supports to sit at either end with holes a little oversize to the dimensions of the legs.

You could rout it or cut the holes in one bit and glue it to another. Lose weight by adapting the design of course . This idea works for me because if you have a heavy bench you put your bar in front of the legs, lift one end and kick it into place. Do the other end. When you are after lowering. Lift kick it forward. Stored under the bench. Whatever floats your boat. Skinning cats... But I think this is the approach I will take. Mine's a 'little' above traditional 'height recommended for hand tools. (Your A***hole to put it bluntly) More I progress I realise I need to utilise two heights for my comfort. You can get round it but for a heavy bench at least it seems a simple solution if muscular approach.

I can't lift my whole bench top on my own. The shape and the weight combine. It's awkward. I can easily lift one end up mind. For those of the Brotherhood Of The Prolapsed Disc (I've got your back lads. Literally), it's probably not the ideal solution. Fair enough.

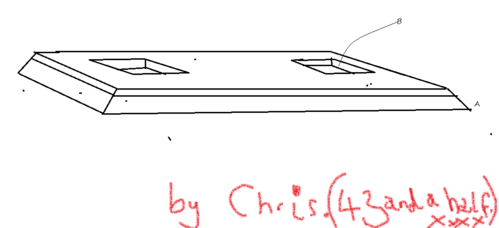

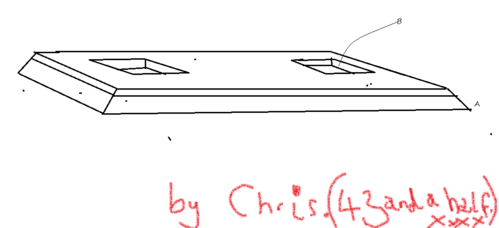

Don't know why people even pay for premium design programmes when you can use Paintshop pro for free and get exactly the same results.

This professional looking CAD image probably only took less than 1 minutes!

I know!

(I'm bang fed up up with rope access work so looking for a career change. Open to offers of design work if it comes from well know and trusted Cabinet makers and fine furniture'ererus of international repute. I'll consider concrete shutterers at a pinch.)

Lons":3sirymm9 said:There must be a way to fit some sort of quick height adjuster on each leg, would need to be substantial easy to wind up and down or wouldn't get used. Needs some thought!

Was wondering about this the other day, began cutting/drilling the mortices out on the underside today on mine and pondering the final height. The solution I came up with was just two extra leg supports to sit at either end with holes a little oversize to the dimensions of the legs.

You could rout it or cut the holes in one bit and glue it to another. Lose weight by adapting the design of course . This idea works for me because if you have a heavy bench you put your bar in front of the legs, lift one end and kick it into place. Do the other end. When you are after lowering. Lift kick it forward. Stored under the bench. Whatever floats your boat. Skinning cats... But I think this is the approach I will take. Mine's a 'little' above traditional 'height recommended for hand tools. (Your A***hole to put it bluntly) More I progress I realise I need to utilise two heights for my comfort. You can get round it but for a heavy bench at least it seems a simple solution if muscular approach.

I can't lift my whole bench top on my own. The shape and the weight combine. It's awkward. I can easily lift one end up mind. For those of the Brotherhood Of The Prolapsed Disc (I've got your back lads. Literally), it's probably not the ideal solution. Fair enough.

Don't know why people even pay for premium design programmes when you can use Paintshop pro for free and get exactly the same results.

This professional looking CAD image probably only took less than 1 minutes!

I know!

(I'm bang fed up up with rope access work so looking for a career change. Open to offers of design work if it comes from well know and trusted Cabinet makers and fine furniture'ererus of international repute. I'll consider concrete shutterers at a pinch.)