Hi All,

Here is a write up of a couple of top cupboards I recently completed. This was my first 5 piece door / shaker type build, and only the second built-in cupboard I have ever done. (The first was a couple of solid pine doors and frame over an alcove).

Lots of lessons learned, which I will go into, but I am pleased with the end result.

The space I am building in is above an existing landing cupboard, most likely built when the (victorian) house was made.

Typical of this type of house, there was not a 90 degree angle in sight, and the walls, ceiling and base were all out of square. I debated whether to build a full carcass, or just frame in the upright panels, to squeeze out those extra few cubic inches of storage, and save on material, given that the wall and ceiling were sound. I went with framing in, rather than building a full carcass:

Each of the three uprights are different depths, because of the wonky wall.

Lessons learned:

1/ In hindsight, I should have just built a nice, square carcass. Yes, it would have cost me a bit of space and a bit of material, but the hassle of covering gaps, painting, wasn’t worth it. Next time, I will just build a carcass and it will make the whole process easier.

Next up, I started on the end panel. My aim was to make it match the original cupboard, made of tongue and groove solid wood:

Luckily, I had hoarded erm... kept some original tongue and groove timber from an old loft hatch in the house. Perfect. So with a bit of cleaning up, filling, glueing, and sawing, I had a perfectly aligned and matching end panel:

<End Panel 1>

Mmmmm, this 120 year old wood smells good, and the shavings looks nice too!

Handy Hint - Huggies baby wipes are great for cleaning glue and a lot of other things! They are unscented and mainly just water.

I used some Morrels one-part wood filler (Light oak coloured, which is what I had on hand). I like it - goes on easily and doesn’t shrink too much, and sands quite nicely)

Now onto the face frames!

When I was in the US at the beginning of the year I picked up a Kreg beading and notching bit, which were significantly cheaper over there. These are the ones:

Kreg PRS4205 1/4-Inch by 2-Inch Notching Bit: Amazon.co.uk: DIY & Tools

And

Kreg PRS4250 1/4-Inch Standard Beading Bit: Amazon.co.uk: DIY & Tools

I didn’t buy the jig - which I think is ridiculously expensive (£350) for what it is:

Kreg Precision Beaded Face-Frame System

First off, testing the beading. I’m using 18mm Medite MRMDF for the face frame. It machined very well. I debated whether to have a quirk alongside the bead, or not. In the end, I decided for the quirk. The quirk on the left edge was far too big, but I settled on the one on the right - looked nicely balanced.

Lesson learned: The MRMDF took the beading very well indeed, but the beading was VERY fragile - any small knock and the MDF would just peel apart. I had to think of something to make this more durable.

Next came the notching for the stiles!

At first I just used the mitre gauge on the router table to notch the rails, but this wasn’t very stable or accurate with longer pieces:

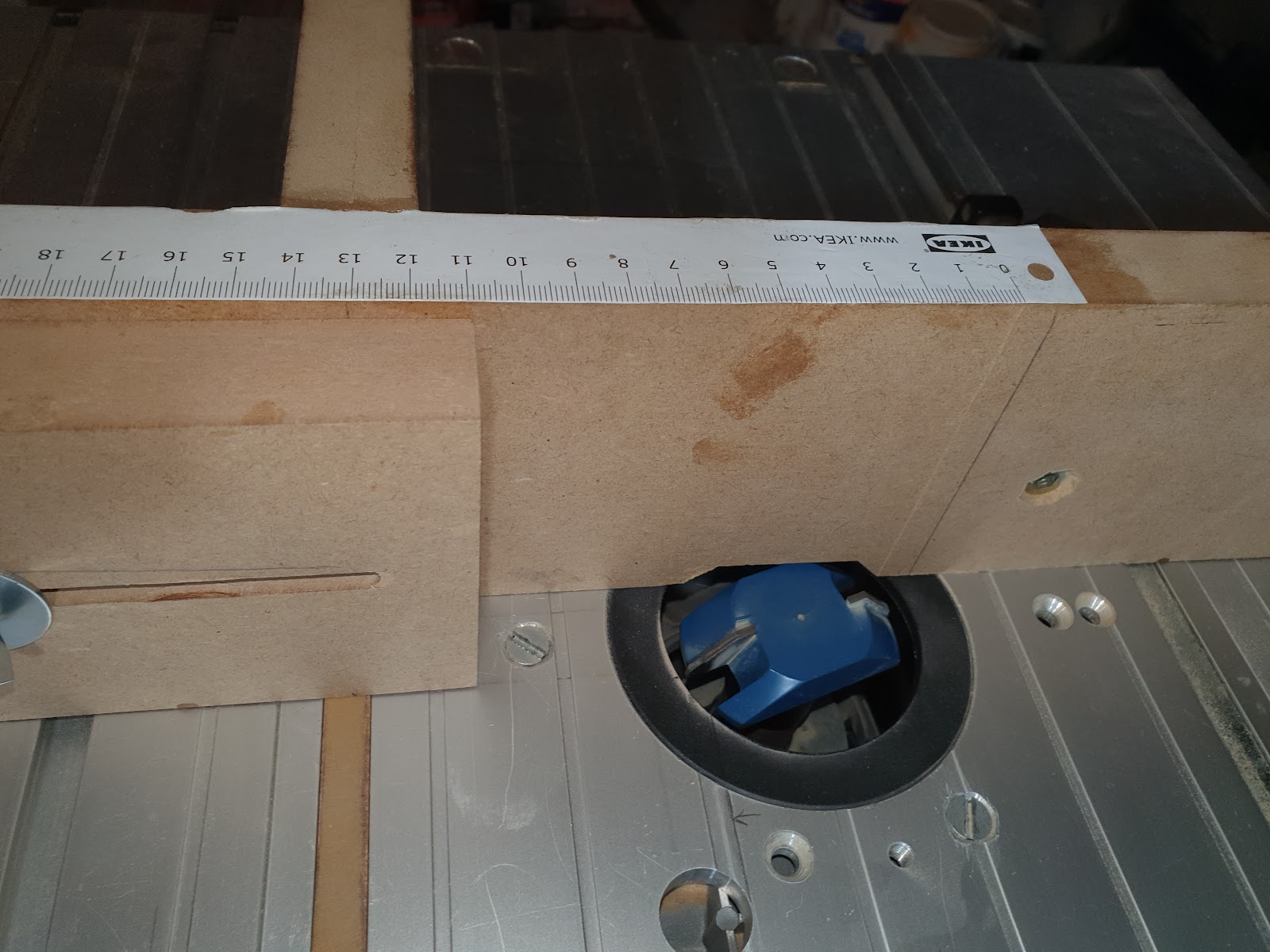

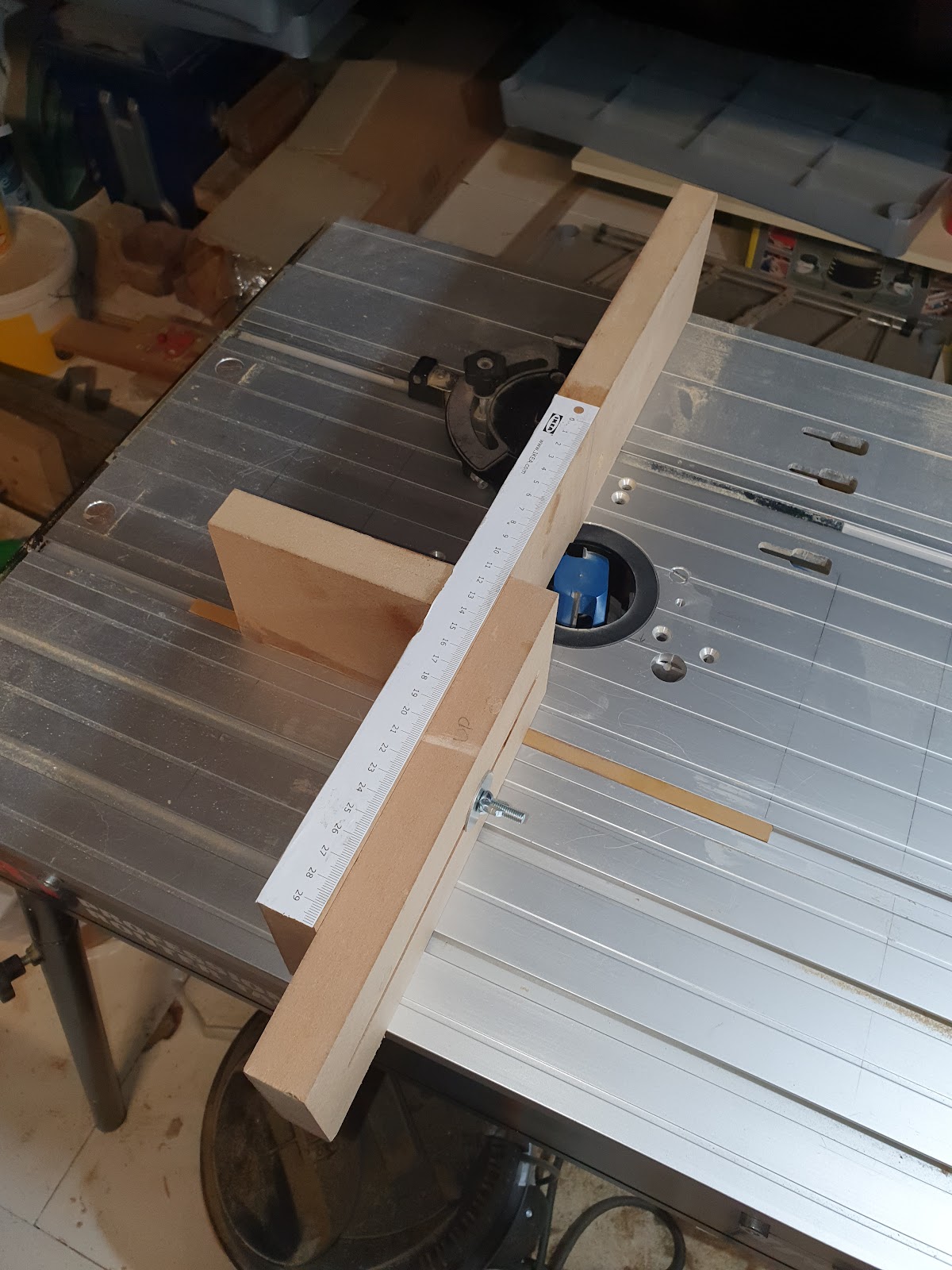

I decided I needed a full width sled, that used two t-tracks so that it holds larger rails perfectly square as it’s pushed over the notching bit. I found some scrap MDF and started building my own simple jig, (and save myself £350):

I added a sliding stop for accurate adjustments.

Handy Hint - the disposable Ikea paper measuring tapes are great for attaching to jigs, and other devices. Bit of Pritt Stick (which doesn’t make the paper soggy), and...:

What I later added (and not pictured) is some Perspex over the central area, just as a guard to keep my hands away from the cutter as I move it.

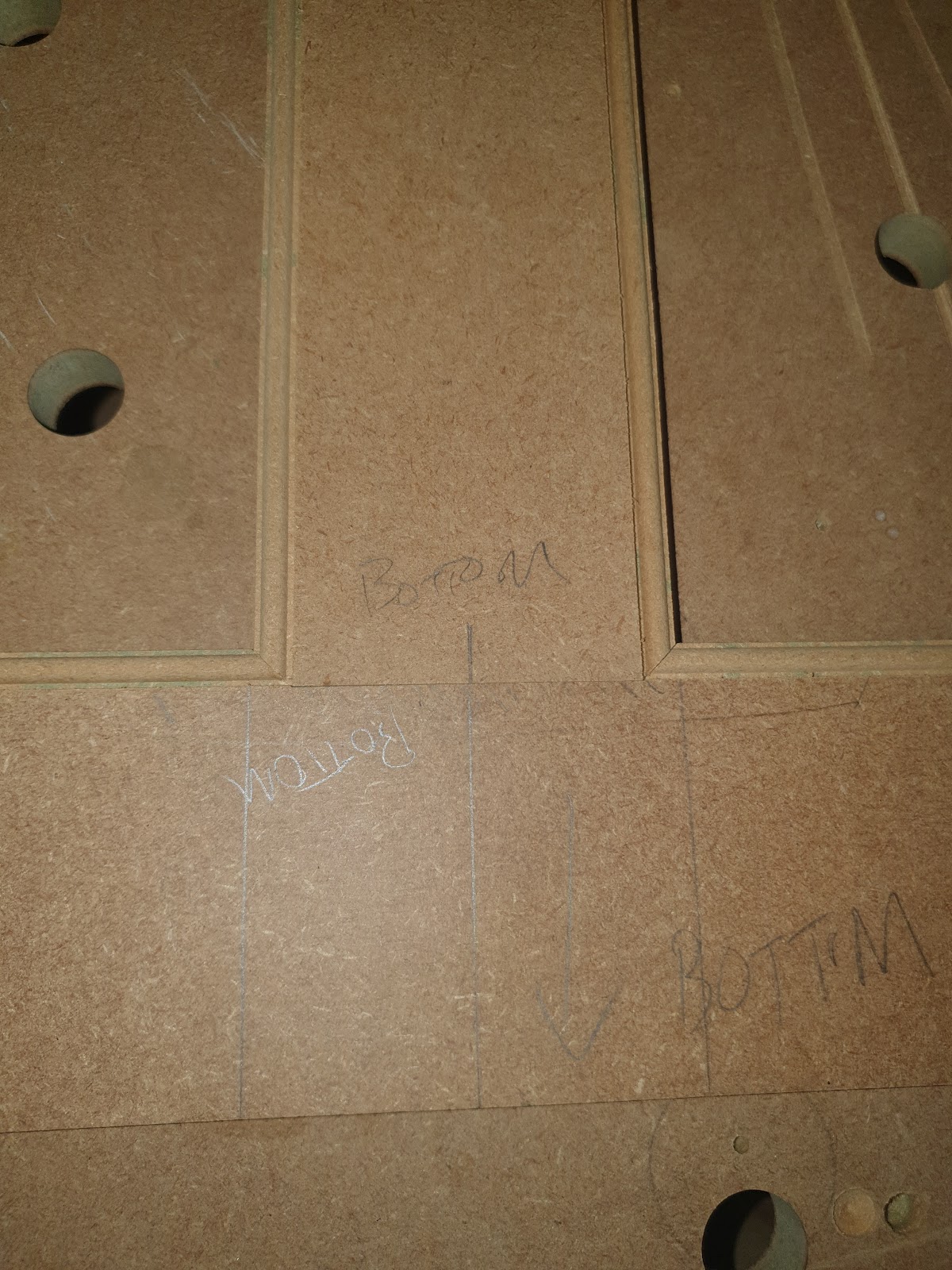

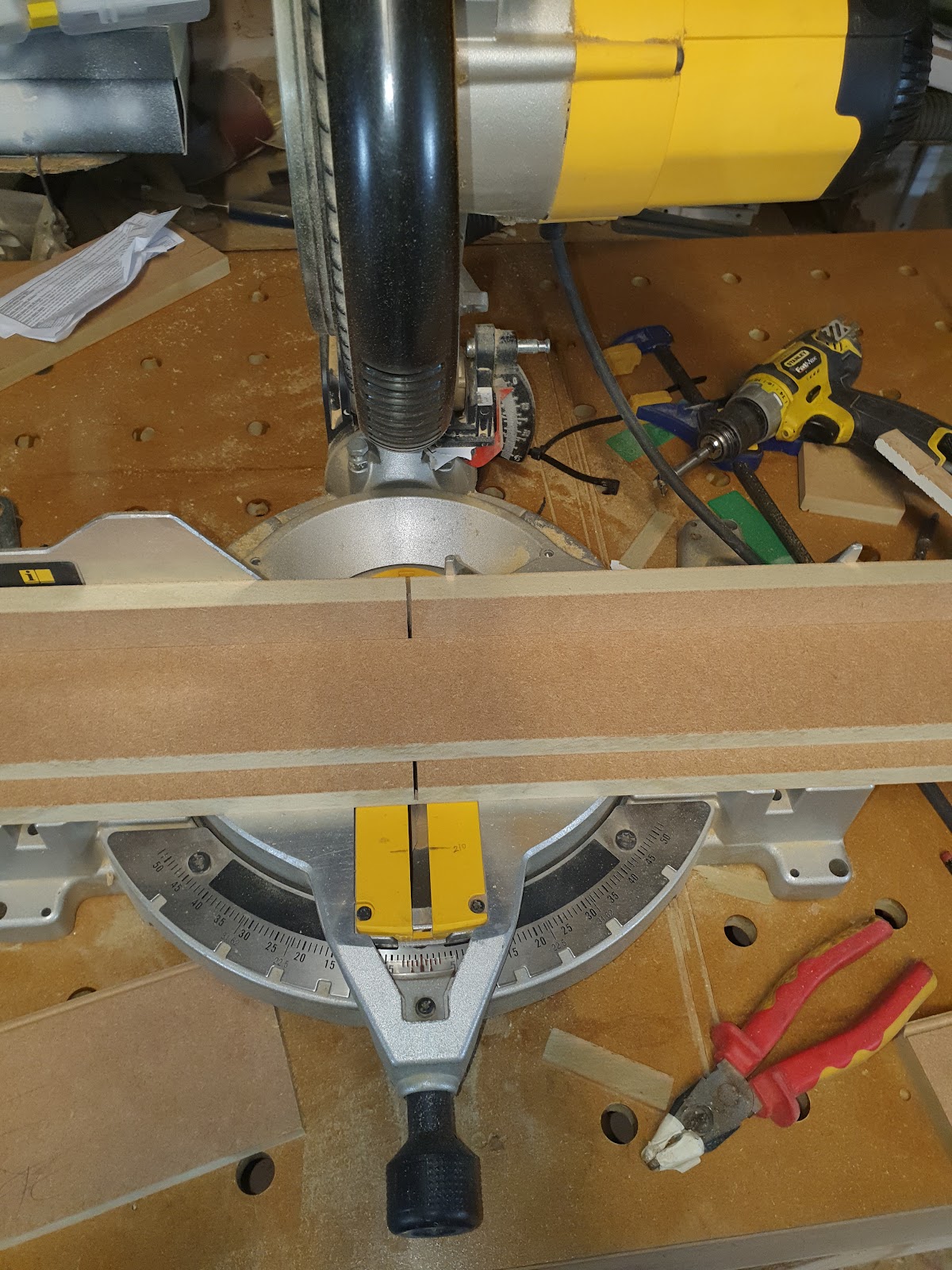

Before I notched the rails, I domino’d the rails and stiles, cutting the mortices a bit deeper to account for the notch depth. The 45 degree ends of the stiles were cut on a mitre saw. It went together quite well:

Lessons learned: I used a 5x30mm domino - I should have used a larger one, like a 8x40m, to make the frame more rigid. I also tried pocket holes - which caused the MDF to bulge. User error I suspect, I need to practice that more.

Glue up time!

I do not have enough clamps or clamping squares to do the whole frame at once, so I started with the middle:

Then the ends:

A light sanding and the joints looked good!

One corner was not so good (the pocket holed joint) - so filler helped me out:

Now, back to the bead. I decided to saturate the bead with cellulose sanding sealer, to give it some strength. A couple of coats soaked right in, and hardly raised the grain. A bit of denibbing and it was totally fine:

Side note:

I was adjusting the fence on my dewalt mitre saw and noticed that the bolts holding the fence were some sort of triangular bolt:

Does anyone know what these are called, and why they are used in this application?

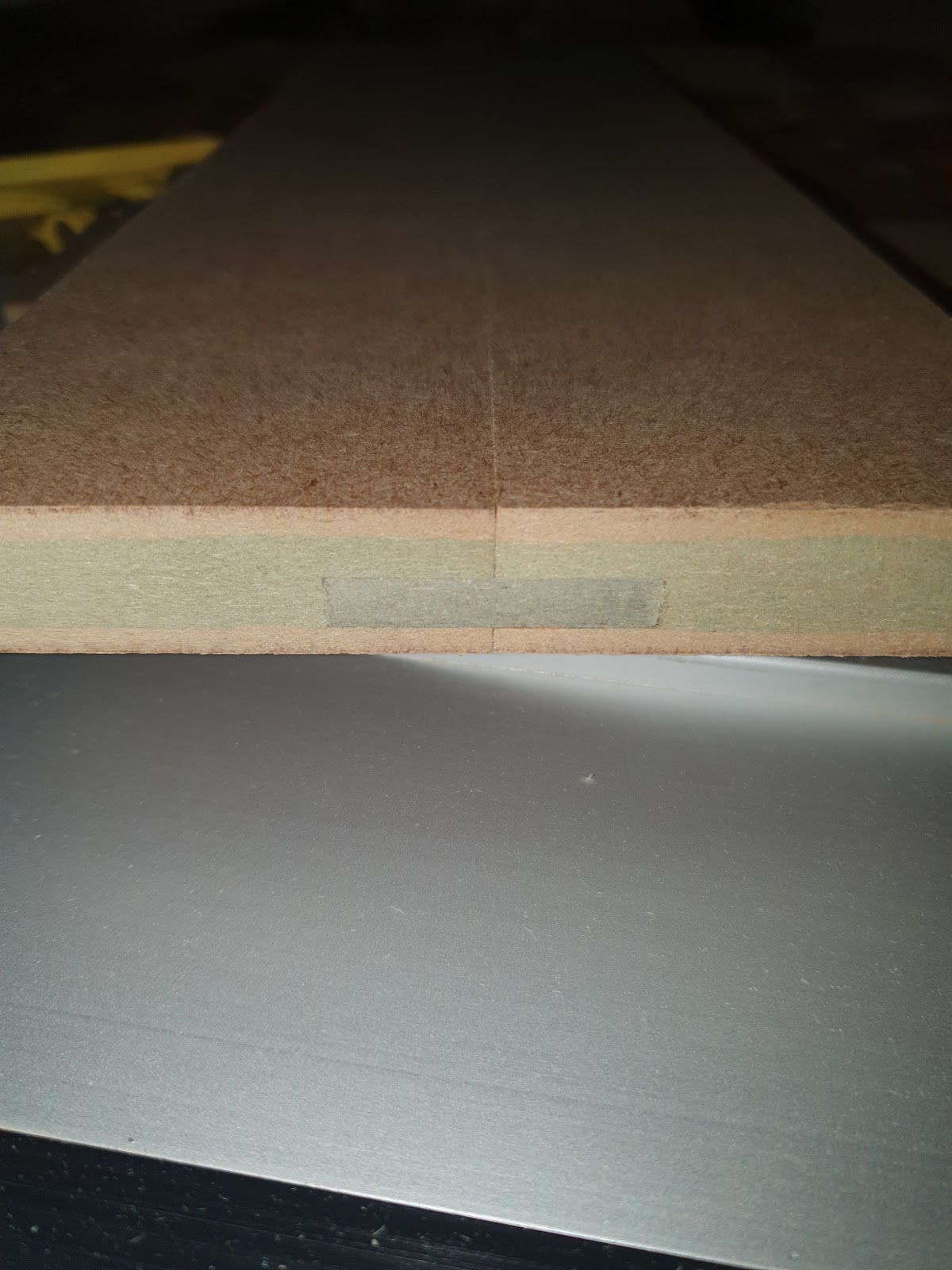

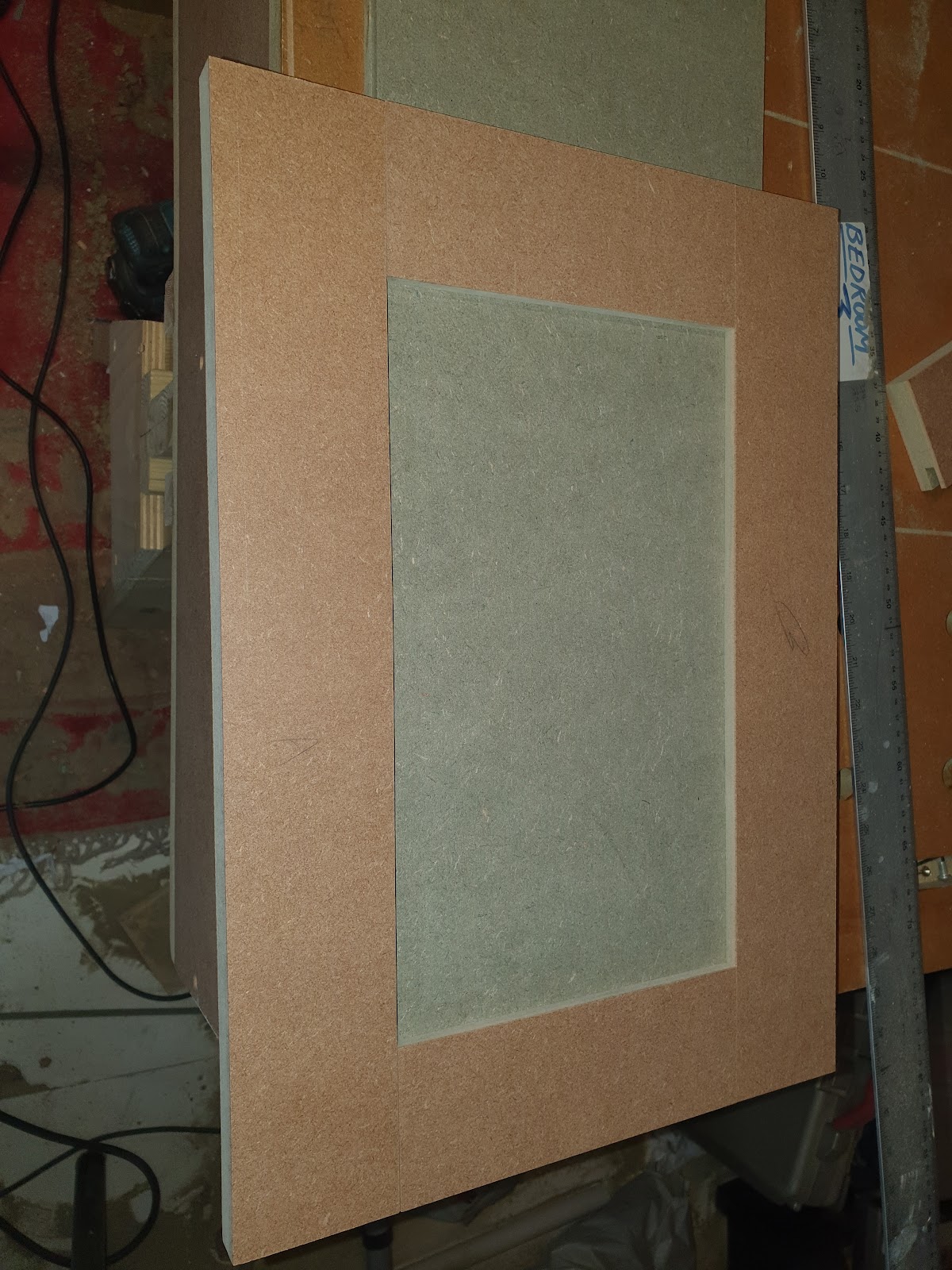

Next I started on the doors.

18mm MRMDF again, since the doors are small, I didn’t need to go to 22mm thick.

The frames are 70mm wide, and will take a 6mm panel. These were made a la @petermillard and his very helpful videos:

I debated how to dimension the doors. Should I make them oversize then trim? Should I allow for a larger gap, to account for the paint?

In the end, I decided to make them to the exact size I wanted - with a 1.5mm gap.

Here is a write up of a couple of top cupboards I recently completed. This was my first 5 piece door / shaker type build, and only the second built-in cupboard I have ever done. (The first was a couple of solid pine doors and frame over an alcove).

Lots of lessons learned, which I will go into, but I am pleased with the end result.

The space I am building in is above an existing landing cupboard, most likely built when the (victorian) house was made.

Typical of this type of house, there was not a 90 degree angle in sight, and the walls, ceiling and base were all out of square. I debated whether to build a full carcass, or just frame in the upright panels, to squeeze out those extra few cubic inches of storage, and save on material, given that the wall and ceiling were sound. I went with framing in, rather than building a full carcass:

Each of the three uprights are different depths, because of the wonky wall.

Lessons learned:

1/ In hindsight, I should have just built a nice, square carcass. Yes, it would have cost me a bit of space and a bit of material, but the hassle of covering gaps, painting, wasn’t worth it. Next time, I will just build a carcass and it will make the whole process easier.

Next up, I started on the end panel. My aim was to make it match the original cupboard, made of tongue and groove solid wood:

Luckily, I had hoarded erm... kept some original tongue and groove timber from an old loft hatch in the house. Perfect. So with a bit of cleaning up, filling, glueing, and sawing, I had a perfectly aligned and matching end panel:

<End Panel 1>

Mmmmm, this 120 year old wood smells good, and the shavings looks nice too!

Handy Hint - Huggies baby wipes are great for cleaning glue and a lot of other things! They are unscented and mainly just water.

I used some Morrels one-part wood filler (Light oak coloured, which is what I had on hand). I like it - goes on easily and doesn’t shrink too much, and sands quite nicely)

Now onto the face frames!

When I was in the US at the beginning of the year I picked up a Kreg beading and notching bit, which were significantly cheaper over there. These are the ones:

Kreg PRS4205 1/4-Inch by 2-Inch Notching Bit: Amazon.co.uk: DIY & Tools

And

Kreg PRS4250 1/4-Inch Standard Beading Bit: Amazon.co.uk: DIY & Tools

I didn’t buy the jig - which I think is ridiculously expensive (£350) for what it is:

Kreg Precision Beaded Face-Frame System

First off, testing the beading. I’m using 18mm Medite MRMDF for the face frame. It machined very well. I debated whether to have a quirk alongside the bead, or not. In the end, I decided for the quirk. The quirk on the left edge was far too big, but I settled on the one on the right - looked nicely balanced.

Lesson learned: The MRMDF took the beading very well indeed, but the beading was VERY fragile - any small knock and the MDF would just peel apart. I had to think of something to make this more durable.

Next came the notching for the stiles!

At first I just used the mitre gauge on the router table to notch the rails, but this wasn’t very stable or accurate with longer pieces:

I decided I needed a full width sled, that used two t-tracks so that it holds larger rails perfectly square as it’s pushed over the notching bit. I found some scrap MDF and started building my own simple jig, (and save myself £350):

I added a sliding stop for accurate adjustments.

Handy Hint - the disposable Ikea paper measuring tapes are great for attaching to jigs, and other devices. Bit of Pritt Stick (which doesn’t make the paper soggy), and...:

What I later added (and not pictured) is some Perspex over the central area, just as a guard to keep my hands away from the cutter as I move it.

Before I notched the rails, I domino’d the rails and stiles, cutting the mortices a bit deeper to account for the notch depth. The 45 degree ends of the stiles were cut on a mitre saw. It went together quite well:

Lessons learned: I used a 5x30mm domino - I should have used a larger one, like a 8x40m, to make the frame more rigid. I also tried pocket holes - which caused the MDF to bulge. User error I suspect, I need to practice that more.

Glue up time!

I do not have enough clamps or clamping squares to do the whole frame at once, so I started with the middle:

Then the ends:

A light sanding and the joints looked good!

One corner was not so good (the pocket holed joint) - so filler helped me out:

Now, back to the bead. I decided to saturate the bead with cellulose sanding sealer, to give it some strength. A couple of coats soaked right in, and hardly raised the grain. A bit of denibbing and it was totally fine:

Side note:

I was adjusting the fence on my dewalt mitre saw and noticed that the bolts holding the fence were some sort of triangular bolt:

Does anyone know what these are called, and why they are used in this application?

Next I started on the doors.

18mm MRMDF again, since the doors are small, I didn’t need to go to 22mm thick.

The frames are 70mm wide, and will take a 6mm panel. These were made a la @petermillard and his very helpful videos:

I debated how to dimension the doors. Should I make them oversize then trim? Should I allow for a larger gap, to account for the paint?

In the end, I decided to make them to the exact size I wanted - with a 1.5mm gap.