Dr Al

Established Member

TheTiddles":12ngm21o said:I’ve just re-read your notes on attaching the top with dowels... I wouldn’t. Whilst you have minimised then shrinkage risk, it’s still there and as you’re doing a decent job of it, go the whole way and use buttons, if you have the biscuit cutter bit you can cut a couple of slots in the rails, make some buttons and you’re done, way better than just sitting it on dowels and another important furniture design/make feature ticked off

Aidan

Thanks for the advice. I hadn't even heard of buttons (although having googled them, I've seen the sort of thing before: just didn't know the name). That sounds like a good plan, although I might have a go at cutting individual slots by hand just for the practice. I'll see what I feel like when I get to that stage!

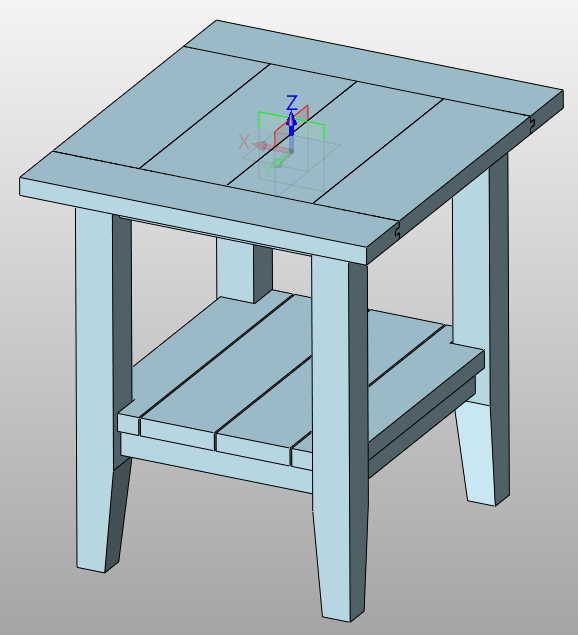

Have you any thoughts about the shelf? If I mount it in a rebate in the lower rail, is there a risk it'll expand and cause a problem? For that matter, if I don't mount it in a rebate, is there a risk that the bit that sticks out between the legs will expand and cause a problem?

Or am I just overthinking this and I should just mount it in a rebate as in the pictures earlier and attach it with buttons?