A couple of months have passed during which time I concentrated on practising on the Scottish Infill Smoother...and the triple checking you have to do to get the infill tight and following the contour. Today I thought of the mistake I made...and was determined not to make the same mistake here.

There are a couple of things aiding me...firstly and foremost...Richard's engineering skills are far greater than the old cast smoother body....and so there is no variation in the geometry anywhere.

Secondly this is not overstuffed so it is a bit easier...but not by much...it's all very easy to think you can relax at any time!

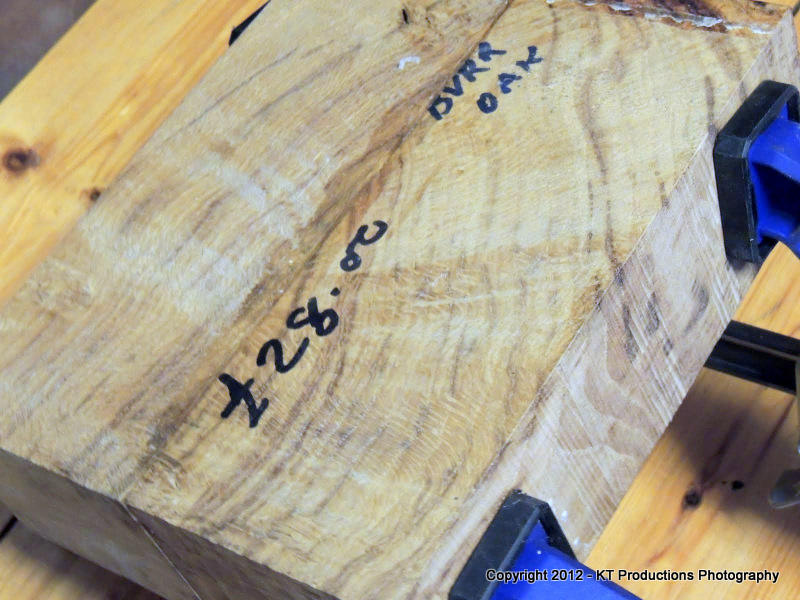

Anyway...yesterday...the first thing I had to do was to join the two halves of the tail infill section so they were hardened by today.....

This was not done to ease the making of the mortice, rather to get a bookmatched finish on the wood. The burr is such a crazy grain though that whatever you try to do...bookmatching is a gamble.....whatever is inside is a present just waiting to be opened...good or bad!

The blocks were way oversized...as you can see....

...but again...that old Burgess made swift work of the two "off cuts!!"

We are still about 8mm over here...4mm each side so that I can slowly creep up on the exact width. A fraction of a mm out means you get a sloppy fit rather than a tight fit.

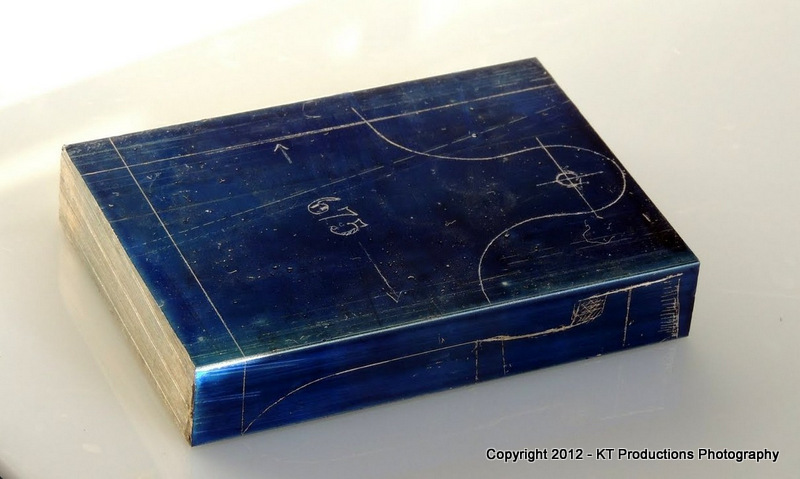

I then took most of the excess off with the mill on one side only....

This gave me a reference side which was perfectly flattened....and then I used that size to make the opposite side exactly parallel....

I wanted to do this to ensure it fitted perfectly but I then made the base at exact right angles using this little beauty....

A bit wide for a jointer...so once I squared up one side I took the fence off and levelled the other side....

...ALFIE was not impressed...this is a long plane to come at you from left field!!!

After that I smoothed the whole lot using my other gem from Phil.....

It didn't even blink through all of the burr and between the two of these marvels...gave me the third side...flat and square.

The final side needed no finishing as this will be cut away later as you will see.

Now to test fit....it was a bit of a struggle and involved quite a large mallet but it went in perfectly....

This is exactly the fit I wanted...certainly not loose but not too tight so that it forced the sides out of parallel...the steel spacer was just held in place...Perfect!

Oh...and I tested the angles on the other lever cap...it's a bit small but you get the idea. And look! The brass arrived for the real one!

I finally sourced a superb place...

Mallard Metals in Brum....and it only cost £40 courier delivered inc. VAT.

A major find this place and superb blokes there who listened to all I needed and came up with the goods. This is machinable and will end up the closest colour to gunmetal when it's finished! Result!

So after a few cups of coffee to steady my nerves...I bit the bullet...trusted in the Burgess and hit the final cuts...

The dreaded curve! And it came up trumps yet again. It was crying near the end but this blade has cut loads of really hard wood lately...so it may need changing soon.....but before I did...how about cutting the notch for the bed insert....

This is a Trojan bit of kit you know. I wouldn't swap it for all the gizmos in China now!

So...did it fit...you bet it did....

This is really going to polish up beautifully..........

.......once I've cut the mortice and stepped tenon for the handle....

Notice here how much the handle has darkened just sitting there for a few months relative to the fresh cut wood.

Oh...and I checked the bed too....

There are a few cracks and chips which is to be expected but these are hidden and will be filled with resin anyway.

The worst bit is over now....so I can concentrate on that lever cap...and the knob. Now that I have the mill...that's going to be a breeze!

More later once I've defrosted!!

Oh.....did you like the gloves! They are Annie's and she's not that impressed as being hairy wool...they seem to have acquired a few shavings today...

I told her...sometimes you have to make sacrifices to achieve the results under adverse conditions! :mrgreen:

That didn't help!!!

Jim