Ha! You guys are so kind! Huge exaggerations but kind, none-the-less!! :mrgreen:

Over the last few nights I have been having nightmares about how to make the bolts for the lever cap! This is one thing that really worried me because I had never made a bolt before and I spent all this time working out how to do it.

In the end..it turned out fairly easy...

First...round bar just a bit bigger than the biggest part of the head...

But setting the edge of the cutting tool at precisely the correct angle for the countersink...I could cut back the stock to way over the required length and create the correct countersink shoulder at the same time.

Note...here I have tested the diameter of the stock at the very end first so I know how far to go for the right thread diameter...or so I thought!

Unfortunately...I measured an M6 bolt when in fact...I was supposed to be making an M5 bolt! (homer)

Now...this sort of error I can cope with...although it was not ideal...but taking more off when you realise is easier than putting it back on again!!

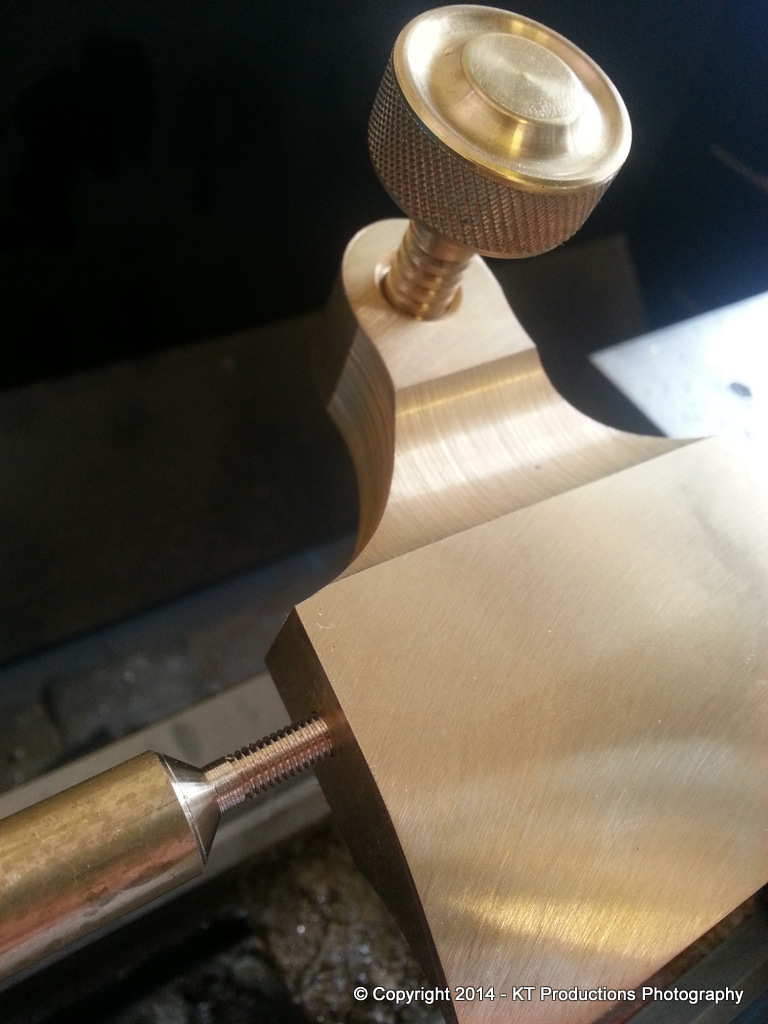

So then I could cut the thread back to the head with the die.

So...just to make sure I had not gone completely mad...I tested it on the lever cap....

Well that worked! :mrgreen:

Now to combine two actions...the cutting of the dome and the parting of the bolt from the stock...

Fortunately the V-cutter had just about the right angle on the other face to leave it was it was and cut back the dome...move and cut again...

(apologies again for a phone shot with poor depth of field!)

Now...I had a rough plan on cutting the slot...varying in setting up a slit saw...to milling using a fine milling bit...but in the end...I just scratched it out with a parting tool and no power on the lathe...

Ok...probably not orthodox but it worked...the brass being very soft and the parting edge being very hard..

But it took a while!! :mrgreen:

Well...it needs a bit of finishing but it came out ok!

And finally to test fit...

I have left it proud...deliberately...while I make the other one (tomorrow!).

I am pretty sure I want to slim it down and get it to hit the steel JUST at the point of the top of the countersink. Also...I have a feeling that I need to reduce the amount of camber in the dome...but again..I want to get used to it and decide.

The old adage that you can take a bit off but you can't add it back on again...definitely applies here!

What do you guys and girls think?

Pete has also confirmed receipt of the thinner of the two blades and I will be sending the other one to Philly once I have these bolts sorted.

Cheers

Jimi