You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The UKW Infill Project

- Thread starter jimi43

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Corneel

Established Member

Great work Jimmie, but there's something I don't understand. Why is the very front of the bun protruding beyond the steel sides?

jimi43

Established Member

Corneel":26toh60x said:Great work Jimmie, but there's something I don't understand. Why is the very front of the bun protruding beyond the steel sides?

From previous experience...a newly cut piece of stock like that..particularly burr which has really strange grain and therefore drying characteristics...tends to continue shrinking.

Indeed, the front piece has shrunk even by a very small amount since I took the plane to Richard's a couple of weeks ago because as it is worked, new open grain is exposed and the moisture remaining seeps out.

As a consequence, the fit is slightly looser than it was back then and I can just remove it now by hand. Before I had to put the spacer back in to remove it and you could hold the plane up by the bun without it falling out.

The sides are not so critical as I am going to screw through this direction anyway but the ends if they shrunk after first shaping would sit below the contours of the surrounding steel and look wrong.

So the next step is to shape the raw steel toe, fix the infill in with screws (removable) and then shape the front and back contours to the body as I have done with the side so far.

Does that make sense?

Jim

Corneel

Established Member

Yes that makes totally sence! (If that is English...)

Good thinking ahead about the shrinking wood.

Good thinking ahead about the shrinking wood.

jimi43

Established Member

It could be indeed Pete...the infill stock has been stored in the workshop all winter so probably picked up quite a bit of moisture during our monsoon season!! :mrgreen:

Ok...enough wood for now....time to try to make a lever cap screw! :shock:

This is going to go one way or another...dreadful or passable...you decide!

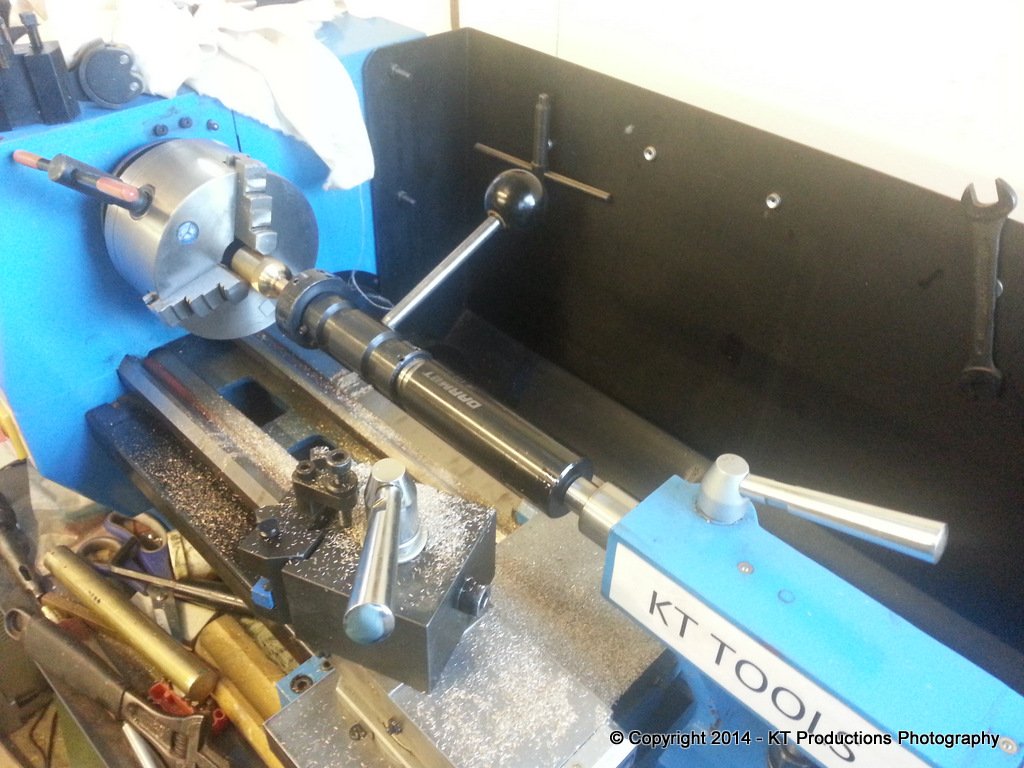

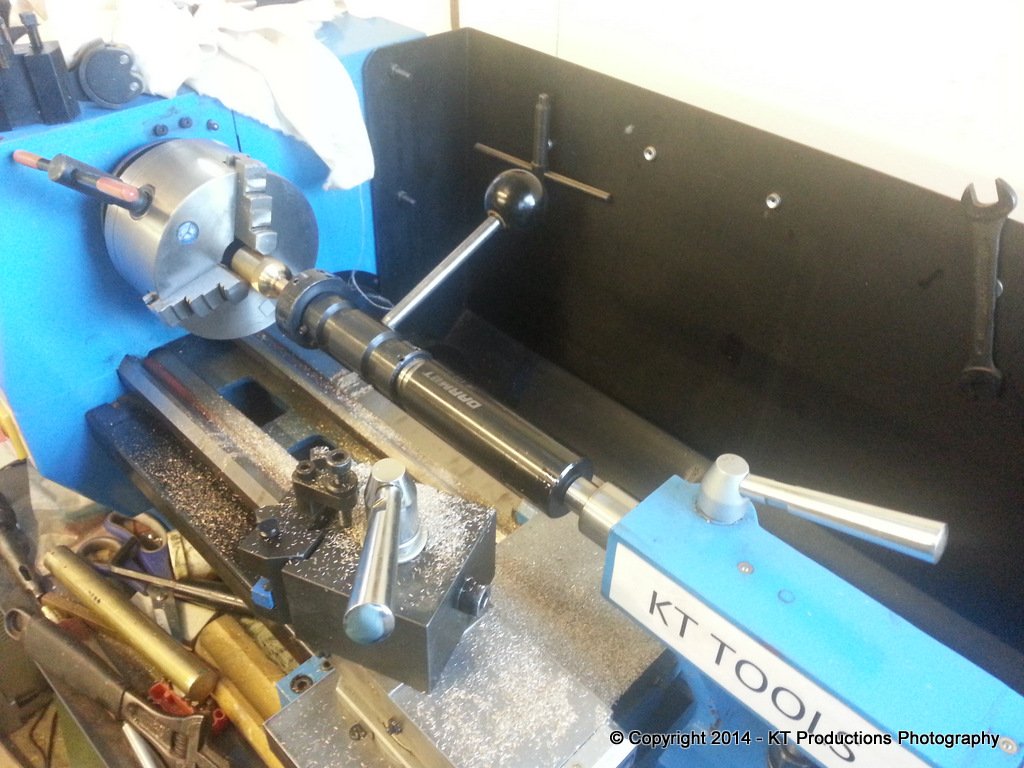

So off to the trusty lathe which Douglas will remember with fond affection since he helped me relocate it from Ruislip to Kent! (thanks again Douglas!)

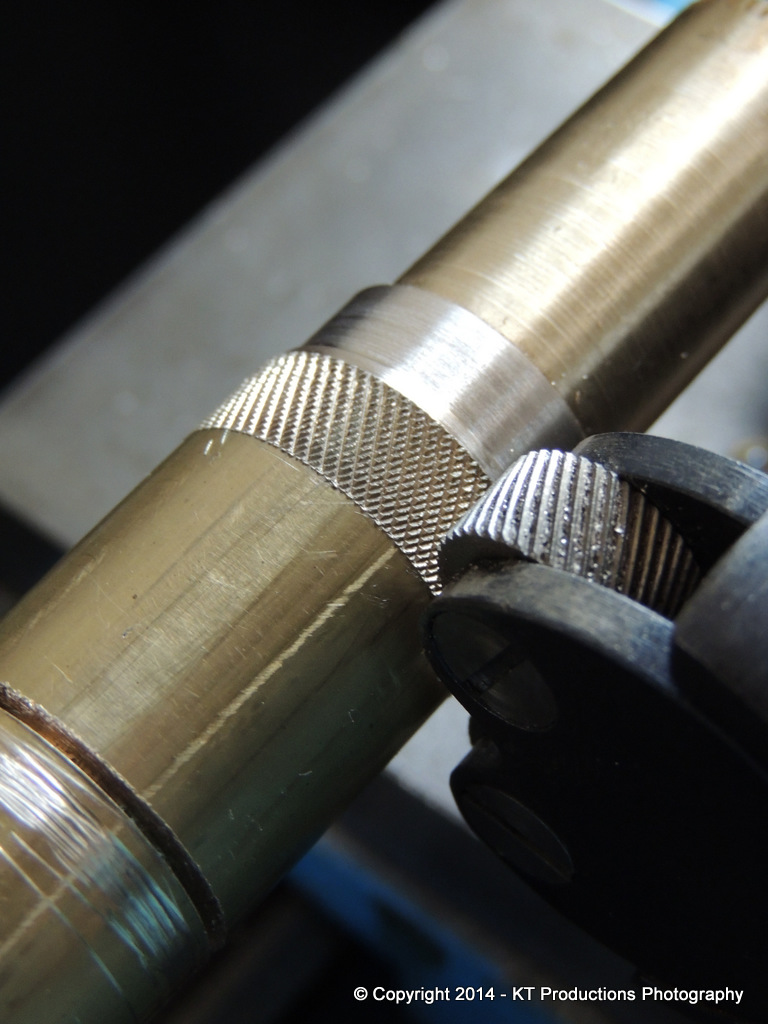

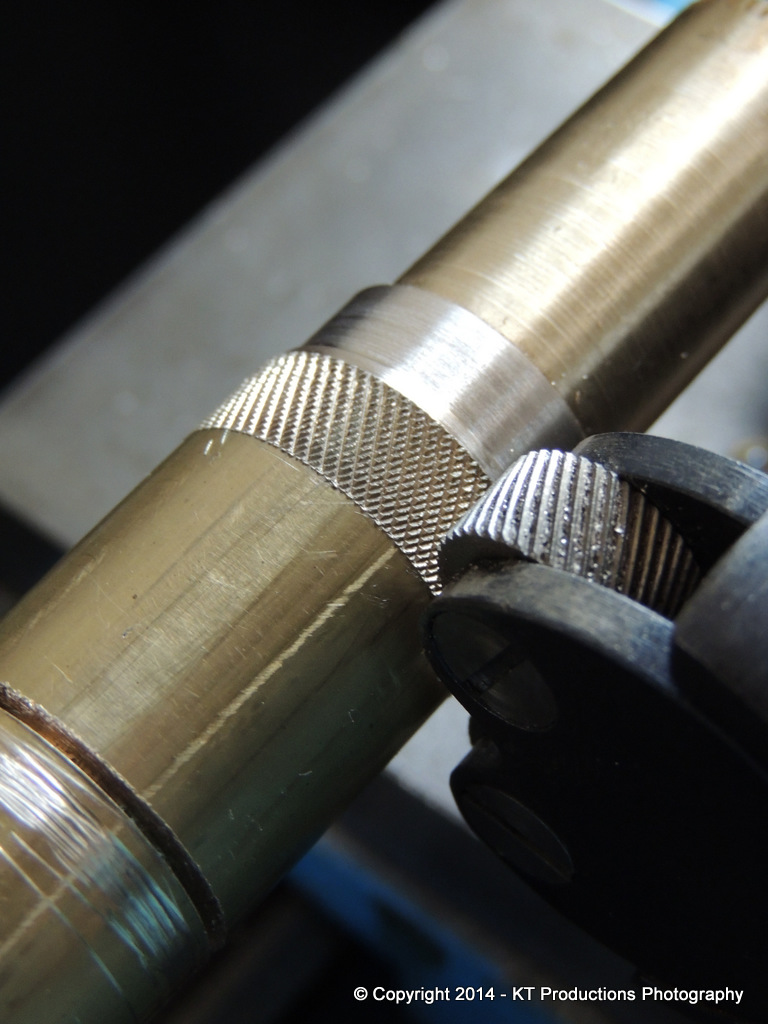

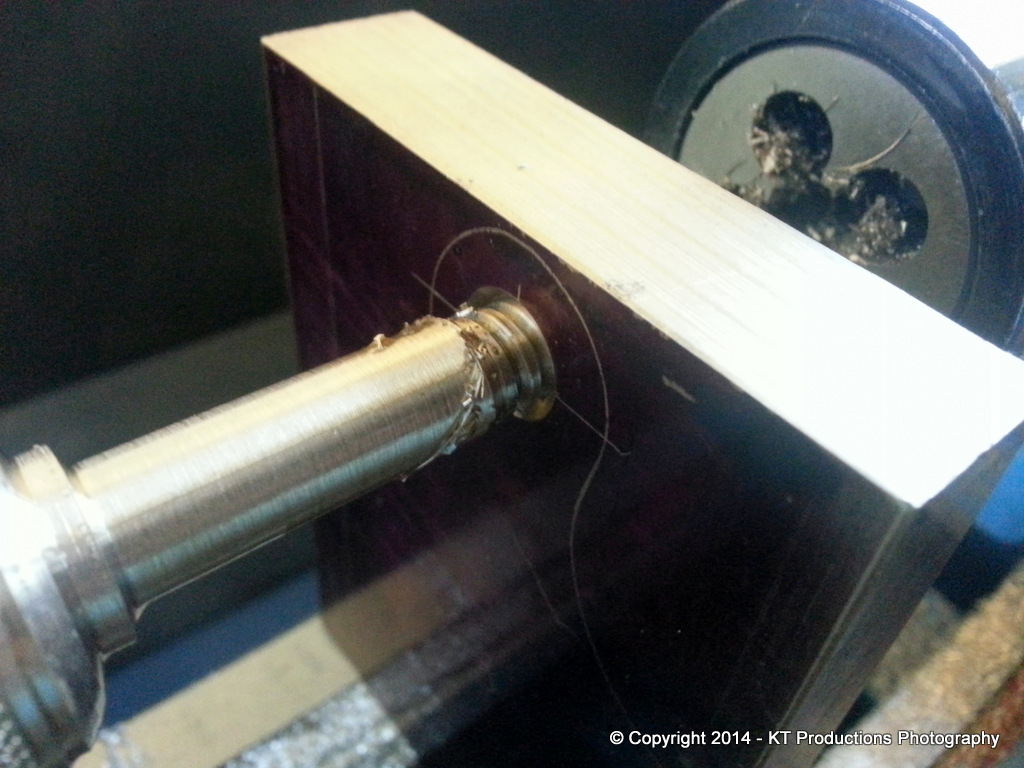

Huge bit of stock because of the knob....and we start with the knurling.

Now I found this J&S knurl tool as NOS at a bootfair a long while back and have been waiting to try it out and it turns out it's the best one I have found....

Very controllable indeed on the varispeed lathe because you just run up to the speed that makes the right chips come out and you're done!

There has been discussion about using three wheel devices but I like this type...plus I don't have a three wheeled one!

Now the crying bit as you have to take off most of the stock to make the thread blank!

Everybody knows what shaving brass off looks like plus I didn't bother photographing that bit so we move swiftly on to the magic tool...

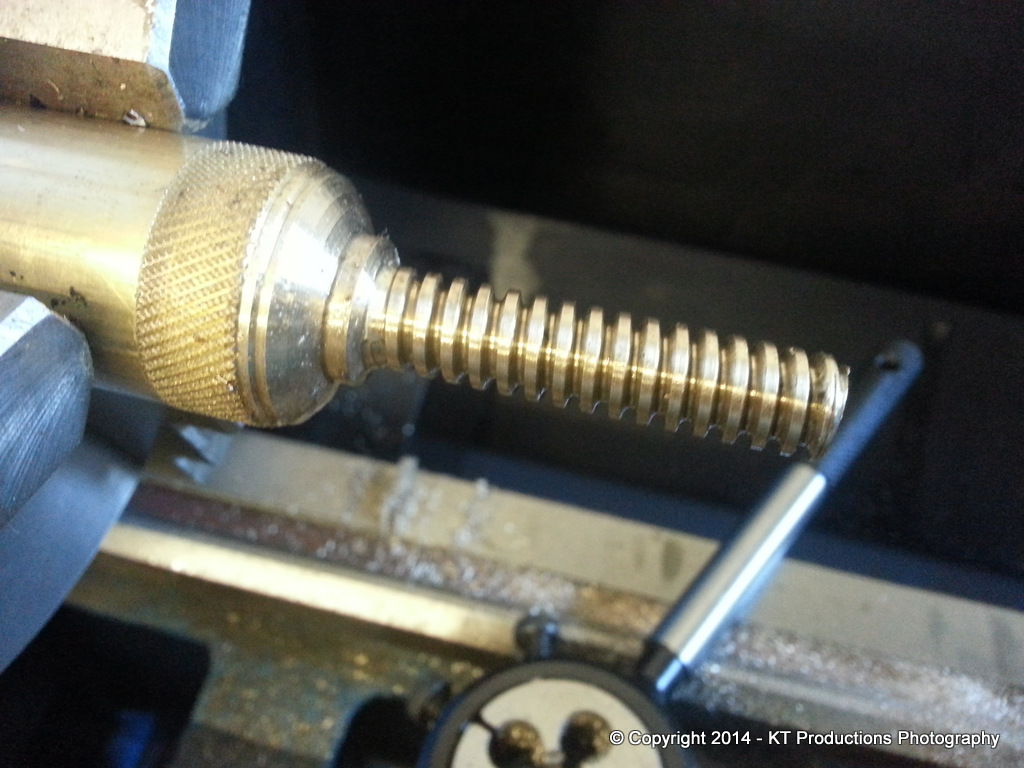

As you can imagine...this thing was not cheap...but I did get it on Fleabay and it was from a bloke in Eynsford Kent so I could pick it up. I have never used it in anger since but tonight...boy was it useful as it holds the die absolutely square and hands-free so you simply have to introduce the stock into the hole.

This is particularly important with this extremely coarse thread as trying to start it by hand is a near impossibility!

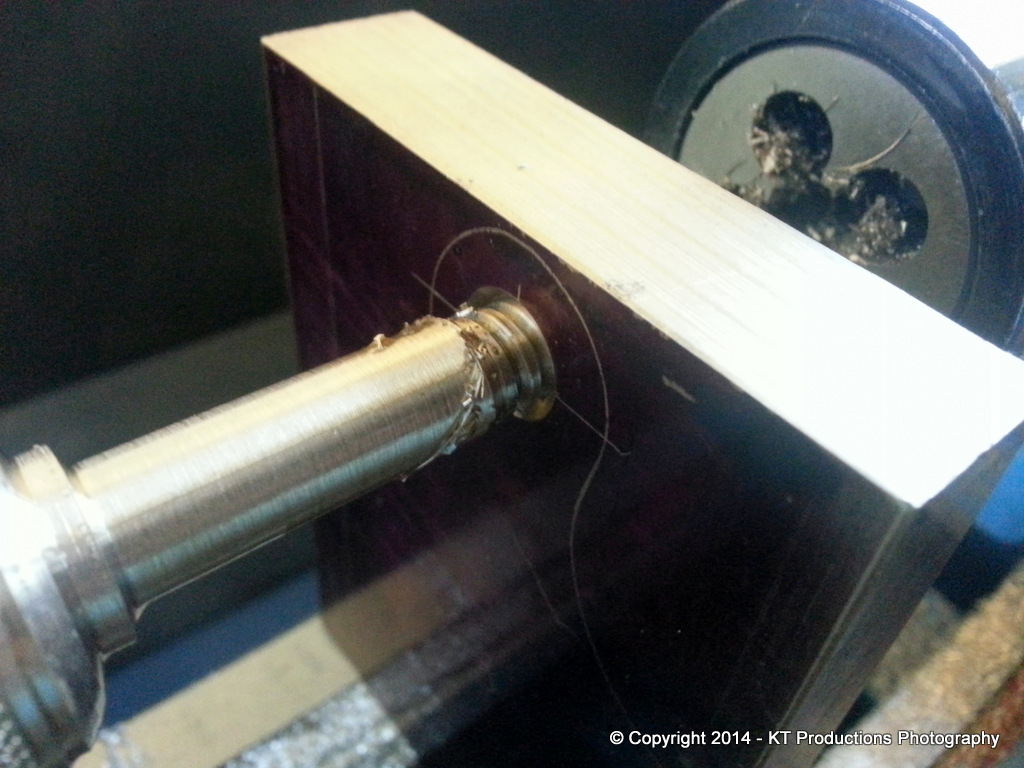

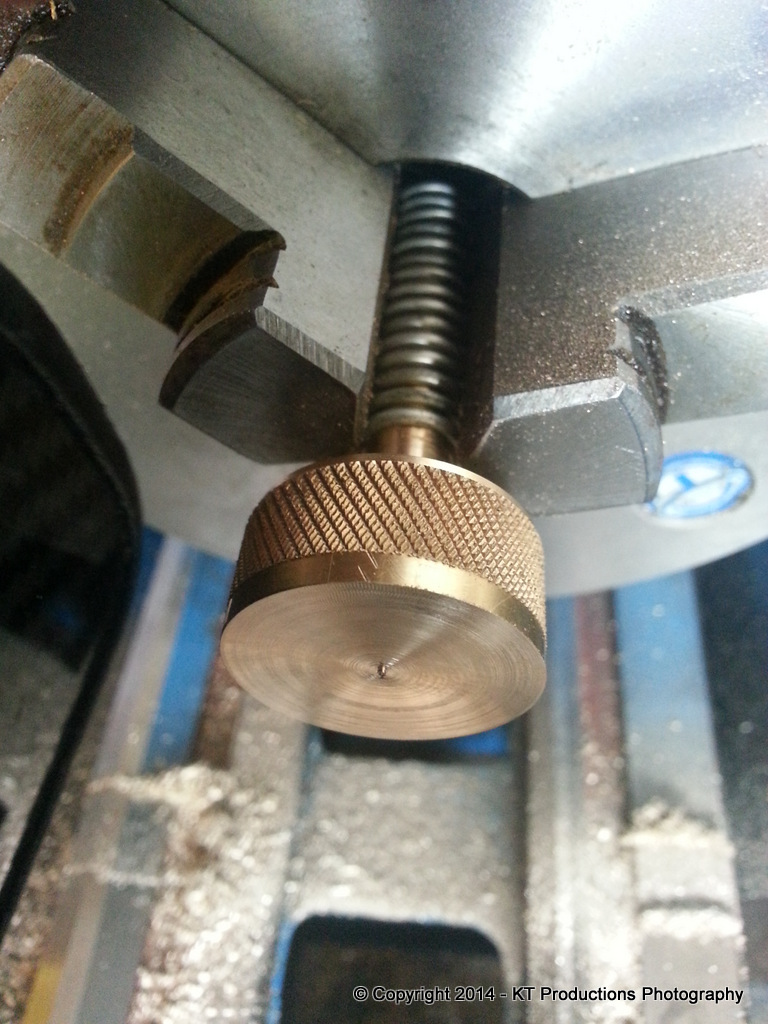

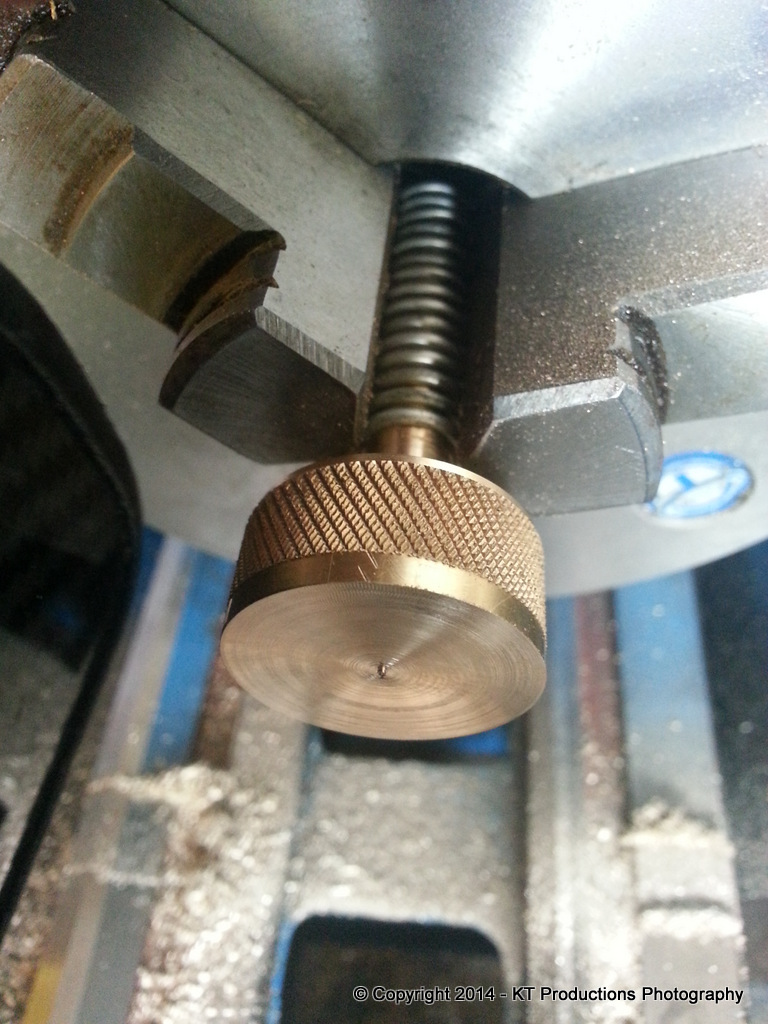

I cut a test lip progressively as I wanted to get the EXACT size that the outer would cut. This prevents overcutting caused by too small stock and ensures you can work up to the right thread fit by tightening the adjustment bolts on the holder and testing every cut pass...like this...

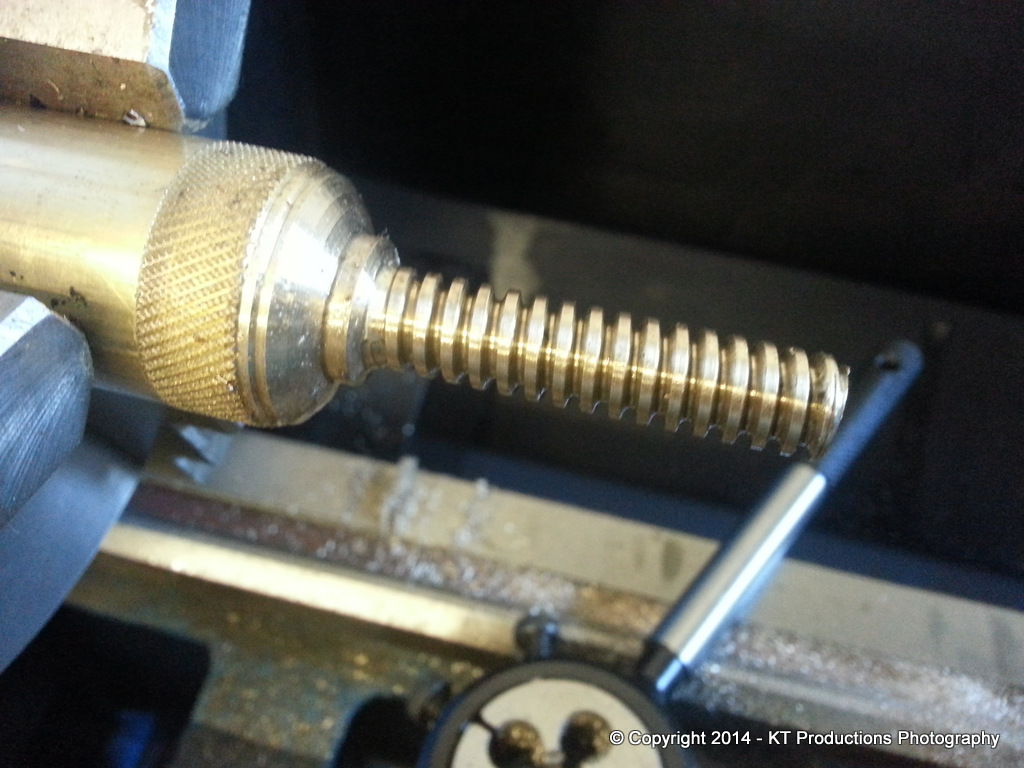

Once I was certain that the bolt fitted the hole and the thread was tight but not too tight I then cut the rest of the thread...

Near the end I cut the whole thing again by hand (yes eagle-eyed will notice the stock on the lathe bench!)

It was VERY tight at first but progressive runs with tiny adjustments to the die brought it up to the right spec...

So that's the difficult bit over with for the night...PHEW!!!

Now all that remains to be done with the bolt is to cut the top and shape the whole thing...oh..and tidy up the end.

Bootfair 5am tomorrow so probably won't get time to do much more before work but we are getting there...

Jimi

Ok...enough wood for now....time to try to make a lever cap screw! :shock:

This is going to go one way or another...dreadful or passable...you decide!

So off to the trusty lathe which Douglas will remember with fond affection since he helped me relocate it from Ruislip to Kent! (thanks again Douglas!)

Huge bit of stock because of the knob....and we start with the knurling.

Now I found this J&S knurl tool as NOS at a bootfair a long while back and have been waiting to try it out and it turns out it's the best one I have found....

Very controllable indeed on the varispeed lathe because you just run up to the speed that makes the right chips come out and you're done!

There has been discussion about using three wheel devices but I like this type...plus I don't have a three wheeled one!

Now the crying bit as you have to take off most of the stock to make the thread blank!

Everybody knows what shaving brass off looks like plus I didn't bother photographing that bit so we move swiftly on to the magic tool...

As you can imagine...this thing was not cheap...but I did get it on Fleabay and it was from a bloke in Eynsford Kent so I could pick it up. I have never used it in anger since but tonight...boy was it useful as it holds the die absolutely square and hands-free so you simply have to introduce the stock into the hole.

This is particularly important with this extremely coarse thread as trying to start it by hand is a near impossibility!

I cut a test lip progressively as I wanted to get the EXACT size that the outer would cut. This prevents overcutting caused by too small stock and ensures you can work up to the right thread fit by tightening the adjustment bolts on the holder and testing every cut pass...like this...

Once I was certain that the bolt fitted the hole and the thread was tight but not too tight I then cut the rest of the thread...

Near the end I cut the whole thing again by hand (yes eagle-eyed will notice the stock on the lathe bench!)

It was VERY tight at first but progressive runs with tiny adjustments to the die brought it up to the right spec...

So that's the difficult bit over with for the night...PHEW!!!

Now all that remains to be done with the bolt is to cut the top and shape the whole thing...oh..and tidy up the end.

Bootfair 5am tomorrow so probably won't get time to do much more before work but we are getting there...

Jimi

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£96.56

£101.95

O'SKOOL Mortise and Tenon Jig is Ideal for cabinets, Chairs, and Table Construction Using a Plunge Router

Amazon US

I'm sure you know this, but when you need to hold that beautifully threaded stem in the chuck so you can shape some pretty curves in the other end, an easy way to avoid damage is to wind some thick wire round the thread.

jimi43

Established Member

Nice isn't it Pete....there's something fundamentally vintage about Acme and other square profiles.

Actually Prof....call me anal...but I was going to make another hole in some scrap round bar and tap it to hold the reversed stock....

I need to shape the transition between the thread and the knurling concave first...then flip it and make a water drop in a pond shape inside the top...

You know the sort!

Probably Monday now...

Jim

Actually Prof....call me anal...but I was going to make another hole in some scrap round bar and tap it to hold the reversed stock....

I need to shape the transition between the thread and the knurling concave first...then flip it and make a water drop in a pond shape inside the top...

You know the sort!

Probably Monday now...

Jim

Corneel

Established Member

I would be very interested to see how you make that "water droplet in a pond". I know this is a woodworking forum, but still....

Corneel":10ctzz0w said:I would be very interested to see how you make that "water droplet in a pond". I know this is a woodworking forum, but still....

I'm wondering about that bit too... and thinking that it might well be easier the old way, with hand held tools on a simple bar toolrest, like a woodturner would use, so you can do a free-hand, compound motion. Brass is quite easy to shape with hand held tools - but that's easy for me to say, when I have not invested hours getting the threading and the knurling just right!! But I'm sure Jim will have some ideas ready by now.

Good stuff, Jim. I feel inclined to try Acme threads now

Turning brass by hand is fairly easy. An HSS wood turning scraper works well. I use a speed of about 700 rpm. It is necessary to experiment with toolrest height and angle of presentation until the chatter-free "sweet spot" is found. Bright mild steel can be turned in the same way.

Turning brass by hand is fairly easy. An HSS wood turning scraper works well. I use a speed of about 700 rpm. It is necessary to experiment with toolrest height and angle of presentation until the chatter-free "sweet spot" is found. Bright mild steel can be turned in the same way.

jimi43

Established Member

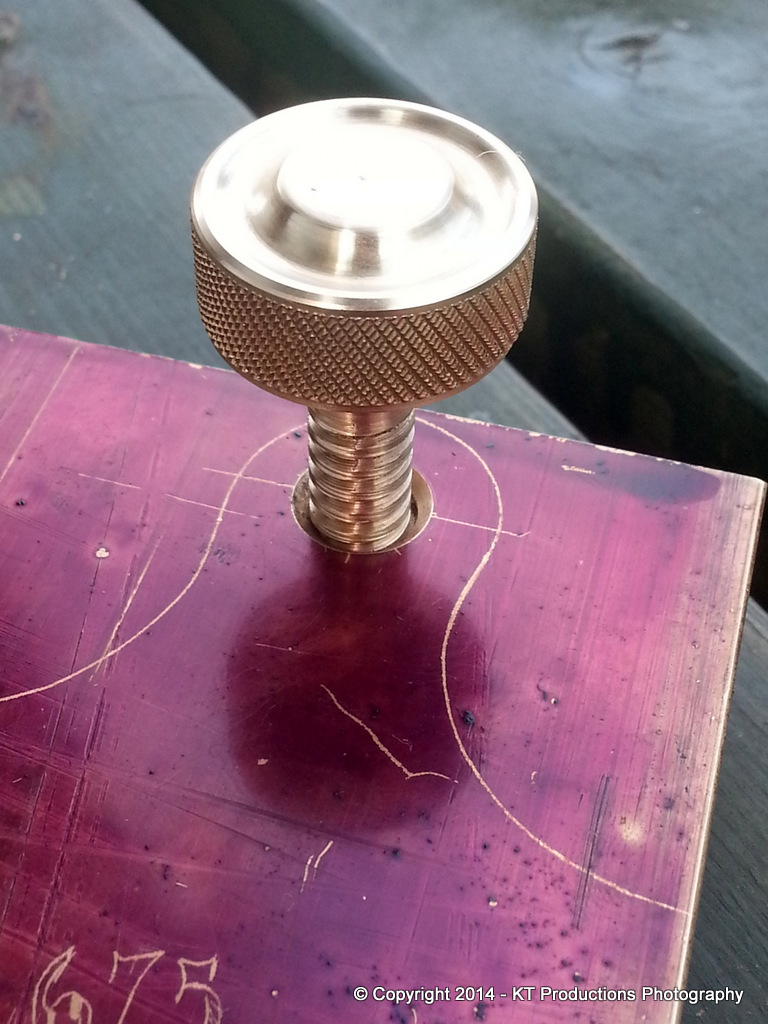

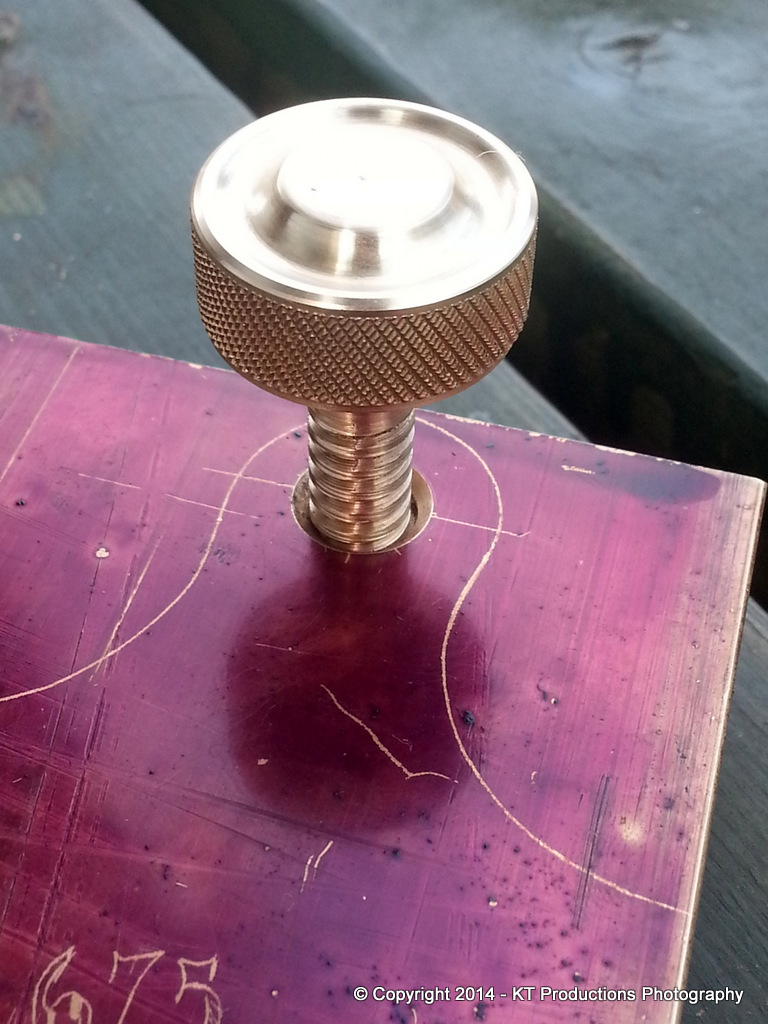

Yes...I don't really know how to describe what I was after doing but it would be like this one but more of a point on the centre:

Usually with concave bits I just shape a bit of tool steel to the contour I want and then introduce it to the stock slowly with plenty of care!

I'm sure it can be done handheld and I can slow the lathe right down...I will probably see how it turns out on a bit of scrap first and go with the best technique.

Cheers guys

Jimi

Usually with concave bits I just shape a bit of tool steel to the contour I want and then introduce it to the stock slowly with plenty of care!

I'm sure it can be done handheld and I can slow the lathe right down...I will probably see how it turns out on a bit of scrap first and go with the best technique.

Cheers guys

Jimi

Corneel

Established Member

Aha, a purpose made tool bit! Why didn't I think of that?

And I didn't know you can shape brass freehand on the lathe. Good to know.

And I didn't know you can shape brass freehand on the lathe. Good to know.

A quick distraction on turning brass by hand, to prove that it can be done - this is my first attempt, and the only one so far. I had been reading "Trustee from the Toolroom" by Nevil Shute, which (unusually for a novel) just happens to have a short description of how to turn a metal egg. It worked, though somehow the scratches look worse in a photo than they do in real life. I mostly used an old engineer's scraper.

jimi43

Established Member

Thank you for your kind comments guys!

Prof..that egg is superb! I shall now have a go at doing it by hand myself (on a scrap bit...I don't trust myself that much! :wink: ). And also...rethinking what you meant by wrapping wire around the thread...I now see exactly where you're coming from there mate..thick wire being like you get in armoured cable..the actual copper single strand...around the deep thread so that the wire is proud all the way along...brilliant!

Sorry...I didn't read it right in the first place and that is certainly a LOT easier than tapping another hole to hold it. I'll give it a go!

"Her indoors" is back this afternoon so I might get some tool time without ALFIE wanting to join in all the time! We'll see! :mrgreen:

Jimi

Prof..that egg is superb! I shall now have a go at doing it by hand myself (on a scrap bit...I don't trust myself that much! :wink: ). And also...rethinking what you meant by wrapping wire around the thread...I now see exactly where you're coming from there mate..thick wire being like you get in armoured cable..the actual copper single strand...around the deep thread so that the wire is proud all the way along...brilliant!

Sorry...I didn't read it right in the first place and that is certainly a LOT easier than tapping another hole to hold it. I'll give it a go!

"Her indoors" is back this afternoon so I might get some tool time without ALFIE wanting to join in all the time! We'll see! :mrgreen:

Jimi

jimi43

Established Member

Ok...peace at last!

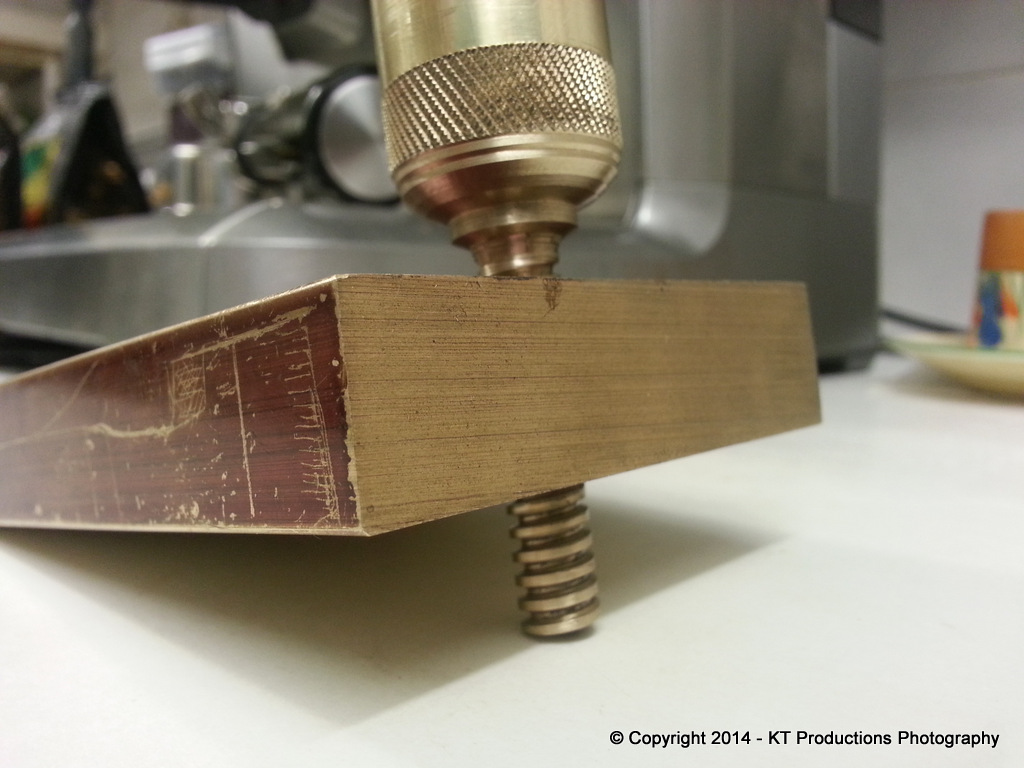

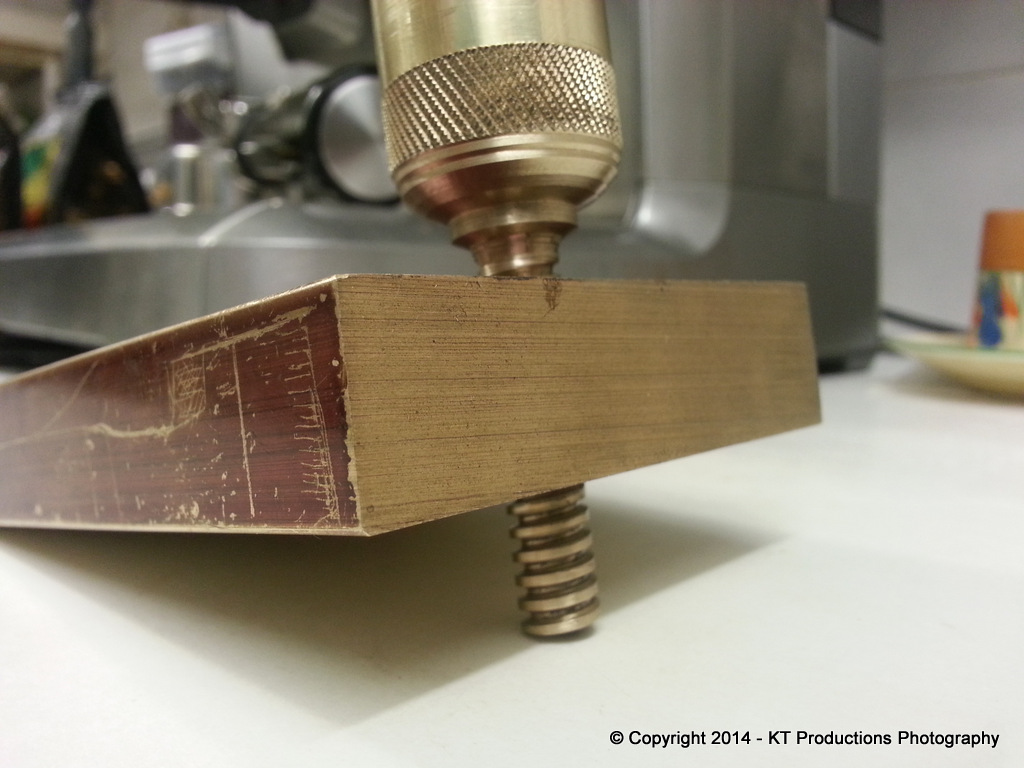

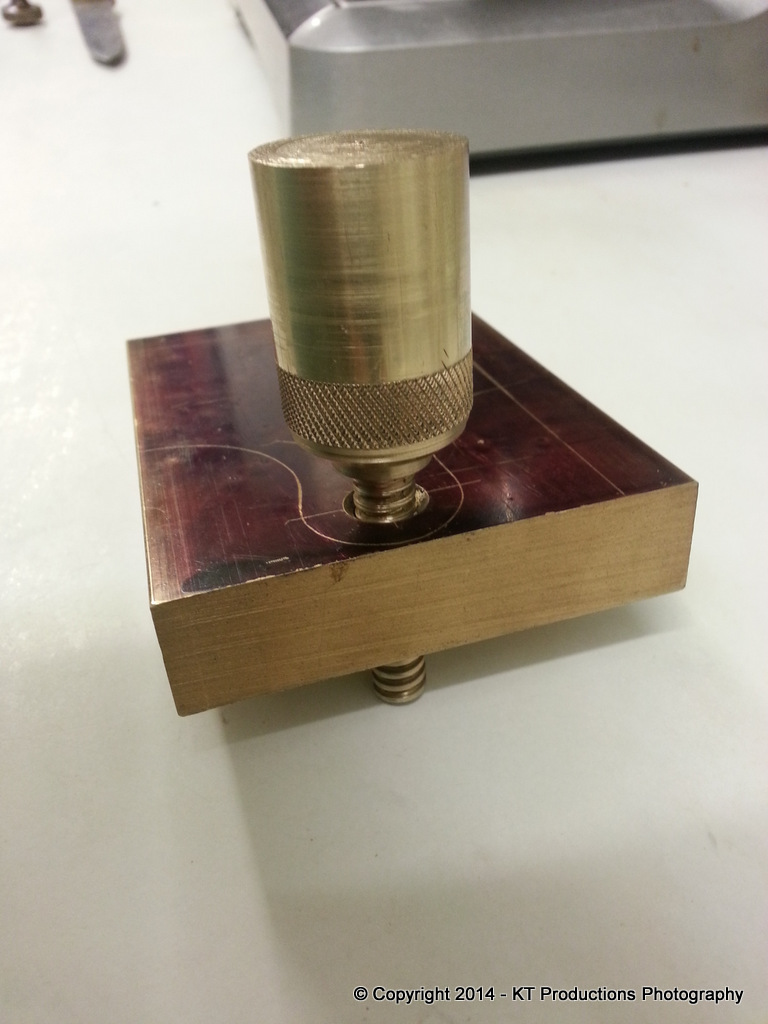

So...first the shaping of the concave underside of the lever cap knob....

Just a gentle curve with a cutter shaped for the job.

Then parting of the piece...slowly!

I found a full roll of thick wire from the days when I made speaker parts...this is for inductors in crossovers....and it worked perfectly....

Thank you so much Prof for that tip...it's a classic...so obvious when you look at it but these simple things often are...most grateful for the time this has saved me.

Makes great springs too...

Even ALFIE was impressed...

...but I did have to pull it away quickly to ensure he didn't eat it! :mrgreen:

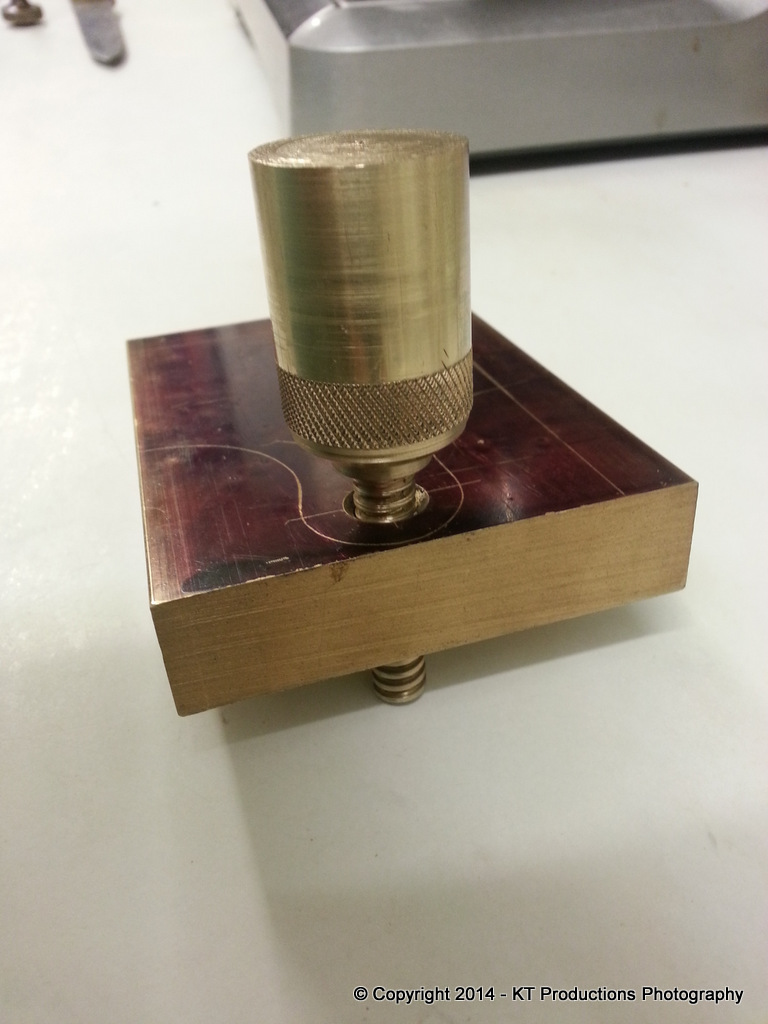

In the chuck the piece is firmly but gently held...

Brilliant!! =D> =D>

The top was then faced off in readiness for the same treatment...

....and I was able to use the same cutter to make the concave dip...

ALFIE then acted as a black background to get a profile shot in contrast....

...although he did insist on showing you all his Jurassic Park "T-REX" impression....(suitably blurred so as not to frighten the kids!) :mrgreen:

I will stare at this for an evening to decide whether to go deeper and more pointed but for now...I quite like the truncated and "butch" version...

...I think it matches the general proportions of the coarse thread and the plane itself.

Tomorrow I shall be mostly cutting the brass block down to width!!! :shock: BY HAND!

Cheers

Jimi

So...first the shaping of the concave underside of the lever cap knob....

Just a gentle curve with a cutter shaped for the job.

Then parting of the piece...slowly!

I found a full roll of thick wire from the days when I made speaker parts...this is for inductors in crossovers....and it worked perfectly....

Thank you so much Prof for that tip...it's a classic...so obvious when you look at it but these simple things often are...most grateful for the time this has saved me.

Makes great springs too...

Even ALFIE was impressed...

...but I did have to pull it away quickly to ensure he didn't eat it! :mrgreen:

In the chuck the piece is firmly but gently held...

Brilliant!! =D> =D>

The top was then faced off in readiness for the same treatment...

....and I was able to use the same cutter to make the concave dip...

ALFIE then acted as a black background to get a profile shot in contrast....

...although he did insist on showing you all his Jurassic Park "T-REX" impression....(suitably blurred so as not to frighten the kids!) :mrgreen:

I will stare at this for an evening to decide whether to go deeper and more pointed but for now...I quite like the truncated and "butch" version...

...I think it matches the general proportions of the coarse thread and the plane itself.

Tomorrow I shall be mostly cutting the brass block down to width!!! :shock: BY HAND!

Cheers

Jimi

Looking good Jim!

I can't remember where I saw the tip about the thick wire - I read quite a lot of old books on turning when I got my metalworking lathe - but I'm glad it worked so well.

I'm sure you will pull all the design elements together in the finished article.

I can't remember where I saw the tip about the thick wire - I read quite a lot of old books on turning when I got my metalworking lathe - but I'm glad it worked so well.

I'm sure you will pull all the design elements together in the finished article.

Mrs T

Established Member

My god, but that's good!

(If this comes out as 'My trousers' or something, I shall be seriously pineappled off).

Really gorgeous work, Jimi.

E

Sent from my ST26i using Tapatalk

(If this comes out as 'My trousers' or something, I shall be seriously pineappled off).

Really gorgeous work, Jimi.

E

Sent from my ST26i using Tapatalk

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 0

- Views

- 178