neilyweely

Established Member

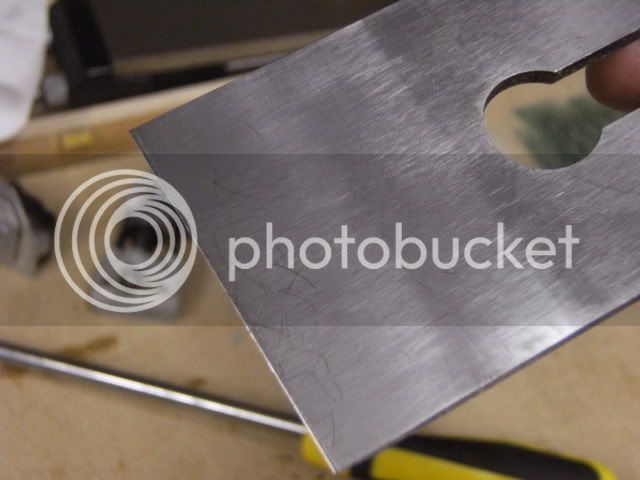

Last week I got my hands on a stanley 200, which as some of you will know is a sharpening jig thingy. I have tried it out and it works well. However I do not seem to be getting the results I want.

I bought a Sorby mortice chisel last month, which was RAZOR sharp out of the pack. Since then I have been trying to reproduce this edge on my other chisels. I have some really nice chisels in the collection, but am loathe to experiment with these on my sharpening system so have been using the draper blue chisels, and a marple 'unbreakable' one to try and get the edge I need. Guess what, no dartchee. I cannot get close.

I have tried a wetstone, diamond system, oil stone, bench grinder and all various combinations of these four. Don't get me wrong I am getting a bloody sharp edge, but not quite.

So, without having to watch hours of video, and cutting all corners possible, can anyone give me a hand? I know you guys are all in possession of positively illegal blades, so whats the trick. I know all about 30' and 25', and to be honest I think I do already know the theory, I just seem to be missing one final factor. I did wonder if it was the cheap chisels that would not even take a good edge, but surely they would take it, just not keep it - right?

Any help greatly appreciated. Thanks. And have a great weekend one and all (Bedford River Festival this weekend, might be good?)

Cheers

Neil

I bought a Sorby mortice chisel last month, which was RAZOR sharp out of the pack. Since then I have been trying to reproduce this edge on my other chisels. I have some really nice chisels in the collection, but am loathe to experiment with these on my sharpening system so have been using the draper blue chisels, and a marple 'unbreakable' one to try and get the edge I need. Guess what, no dartchee. I cannot get close.

I have tried a wetstone, diamond system, oil stone, bench grinder and all various combinations of these four. Don't get me wrong I am getting a bloody sharp edge, but not quite.

So, without having to watch hours of video, and cutting all corners possible, can anyone give me a hand? I know you guys are all in possession of positively illegal blades, so whats the trick. I know all about 30' and 25', and to be honest I think I do already know the theory, I just seem to be missing one final factor. I did wonder if it was the cheap chisels that would not even take a good edge, but surely they would take it, just not keep it - right?

Any help greatly appreciated. Thanks. And have a great weekend one and all (Bedford River Festival this weekend, might be good?)

Cheers

Neil