Sawdust=manglitter

Established Member

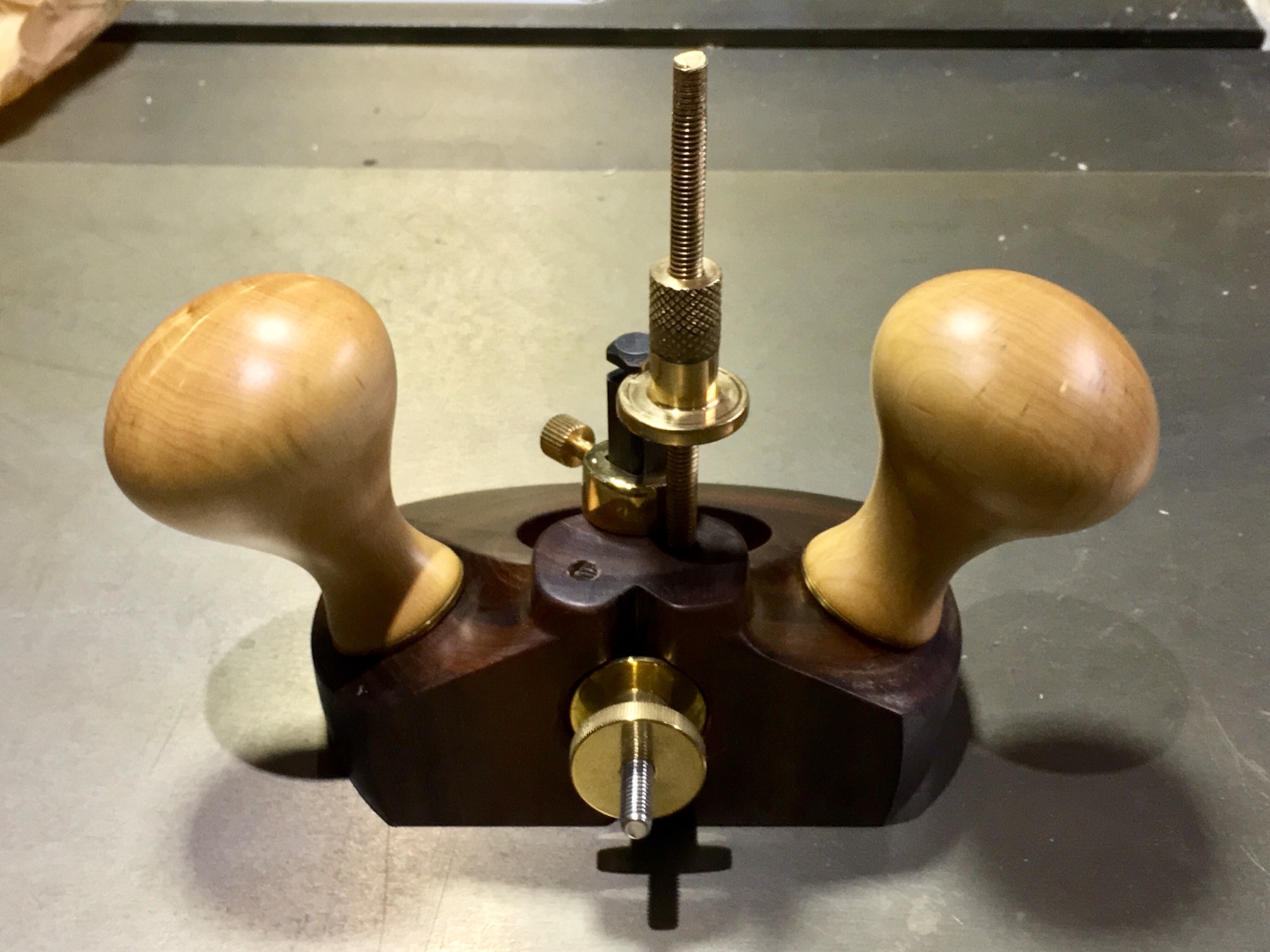

Back to the WIP...

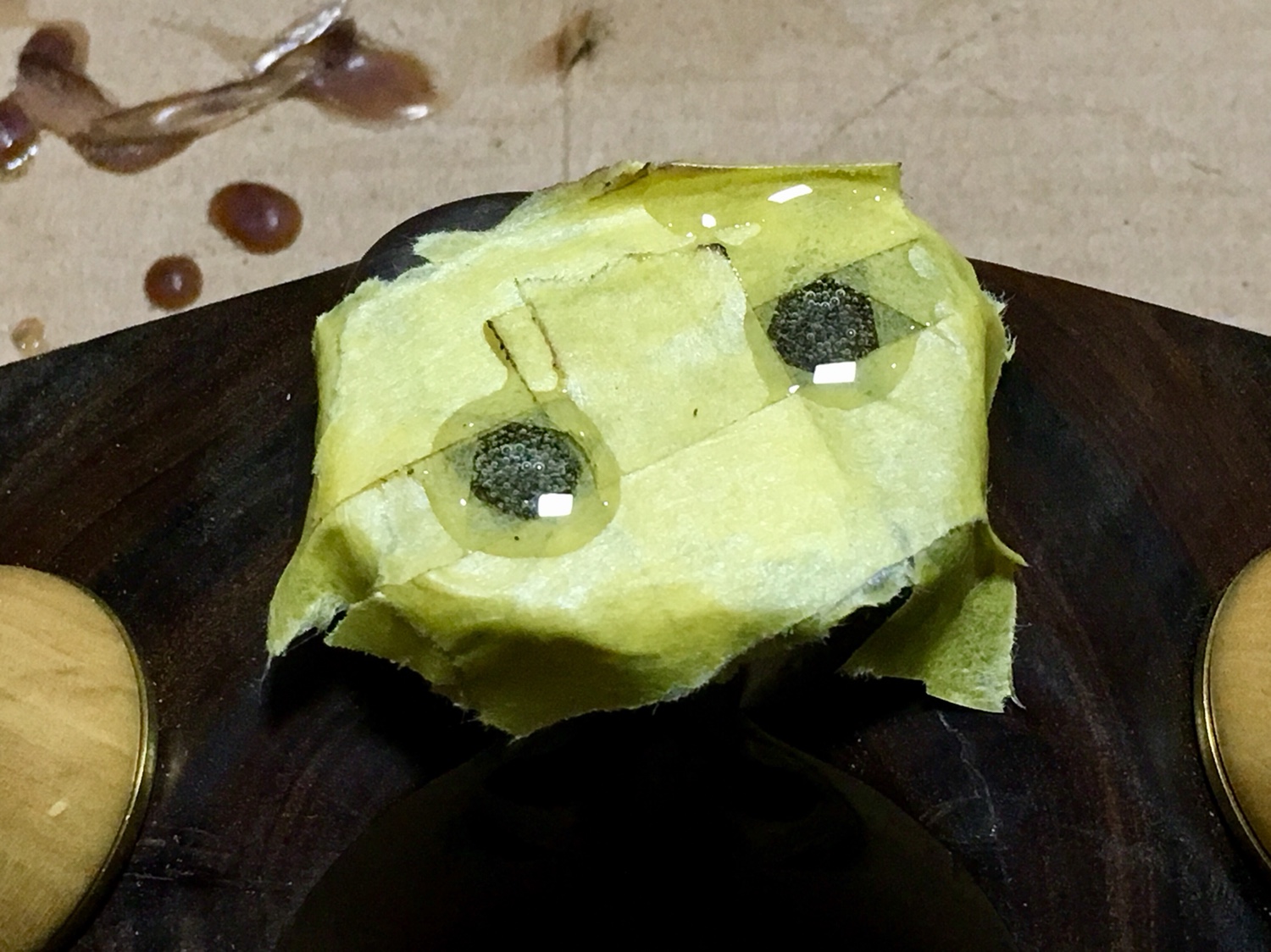

In the meantime I’d bought a couple of the Veritas router plane blades, so I had them for accurate sizing. For the depth stop I bought a short length of 22mm diameter brass rod from eBay. So as there was a lot of experimentation during this build I thought I’d try and drill a hole into the rod using the wood lathe, so I mounted the rod in my chuck using the centre of the jaws to secure the rod (hopefully) central. I then drilled a small hole (maybe 4mm) and then worked up from 6mm to 8mm and finally to a 10mm diameter hole - also used 3 in 1 for lubrication, rightly or wrongly!

Once I drilled the hole I did a little shaping of what would be the top face of the depth stop using a file while the lathe was on. The i sanded it using the micro-grit pads.

In order to cut it off, again rightly or wrongly, I carefully moved a hacksaw forwards while the lathe was on in order to cut the correct length almost all the way through, but tuned off when I was close to actually saw the rest off with the hacksaw properly. Note that I found it a cleaner/slower/less scary cut with the teeth of the hacksaw blade facing the wrong way.

I cleaned up the burrs to the bottom face of the depth stop using sand paper, working my way through the grits by rubbing on my table saw table, and even went through the micro-grit pads to an unnecessary 12000 grit.

I have some cheapy small files which I randomly received among random tools that came with my lathe, which I used to try to form internal corners of the hole in the depth stop to try and make a nicely fitting square hole the right size for the Veritas blades, which took a while.

[As a side note, I bought a second cut and smooth cut Bahco 10mm square files (which are great by the way!) for this and for making the V-groove in the body, but I wish I’d gone for the 8mm square files as the 10mm files were too big to use effectively until the hole was already big enough for the depth stop, so I was only able to use the top tapered area of the files.]

Anyway, got there in the end and then drilled and tapped a hole for an M4 knurled bolt (which I got here... https://www.amazon.co.uk/gp/product/B07 ... UTF8&psc=1 - again, a lot more than I need, but will no doubt come in handy for future projects in years to come)

As you can tell from the above and below photos, the hole isn’t the tidiest and was actually a little too big/loose for my liking as it wobbled to either side of the knurled bolt a bit when tightened(so would be too inaccurate for me as a depth stop), so this was my first attempt and I have since made another tidier, better fitting one.

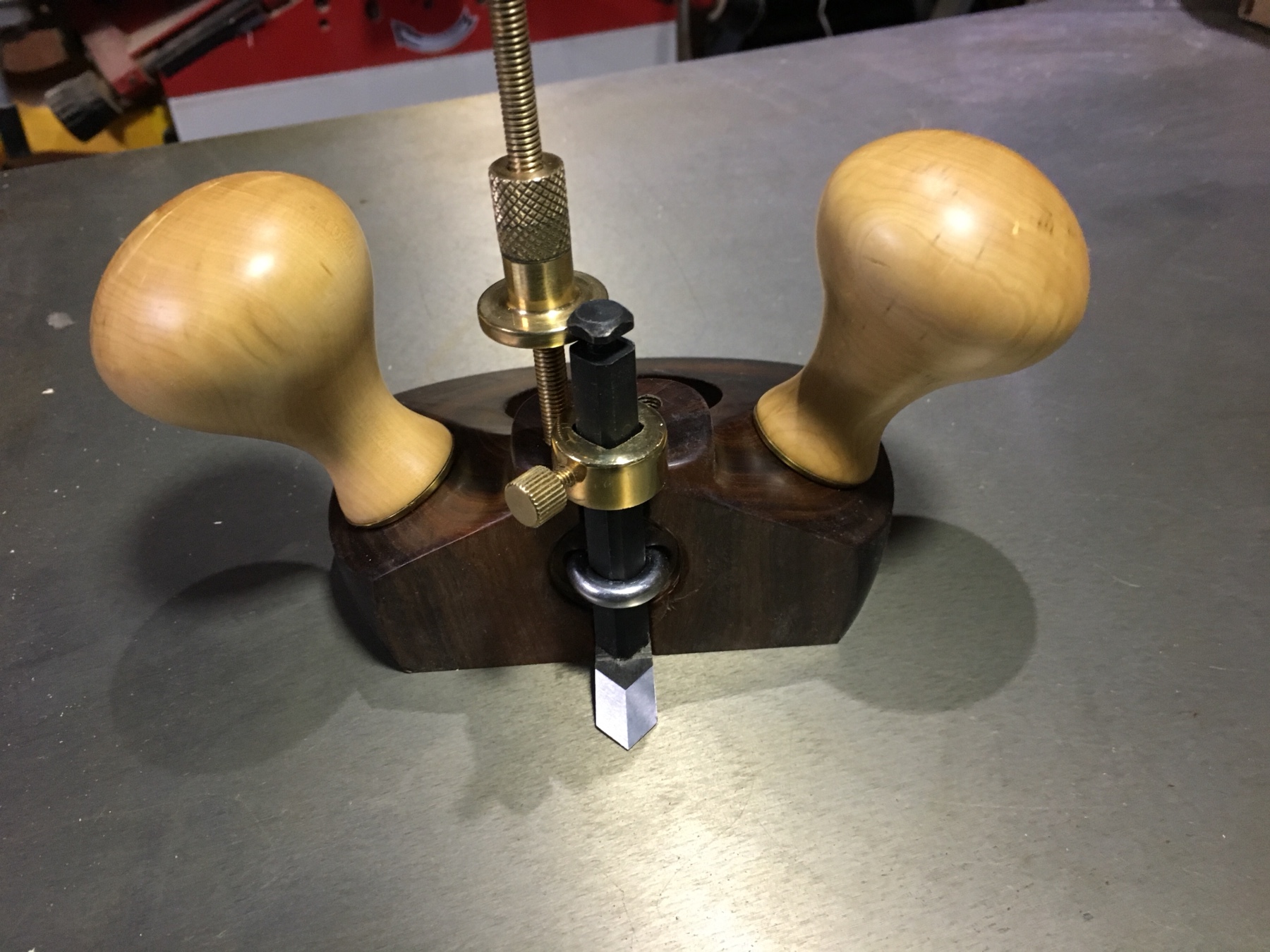

So on to the blade clamp...

So I bought this eye bolt from eBay

https://www.ebay.co.uk/itm/2-Pack-M6-Th ... 1438.l2649

As it actually gave the inside diameter as 10mm, which is needed for the blades. So similarly to the depth stop above, I used a combination of the small files and the top tapered end of the 10mm square Bahco files to form a nicely fitting square hole for the blades.

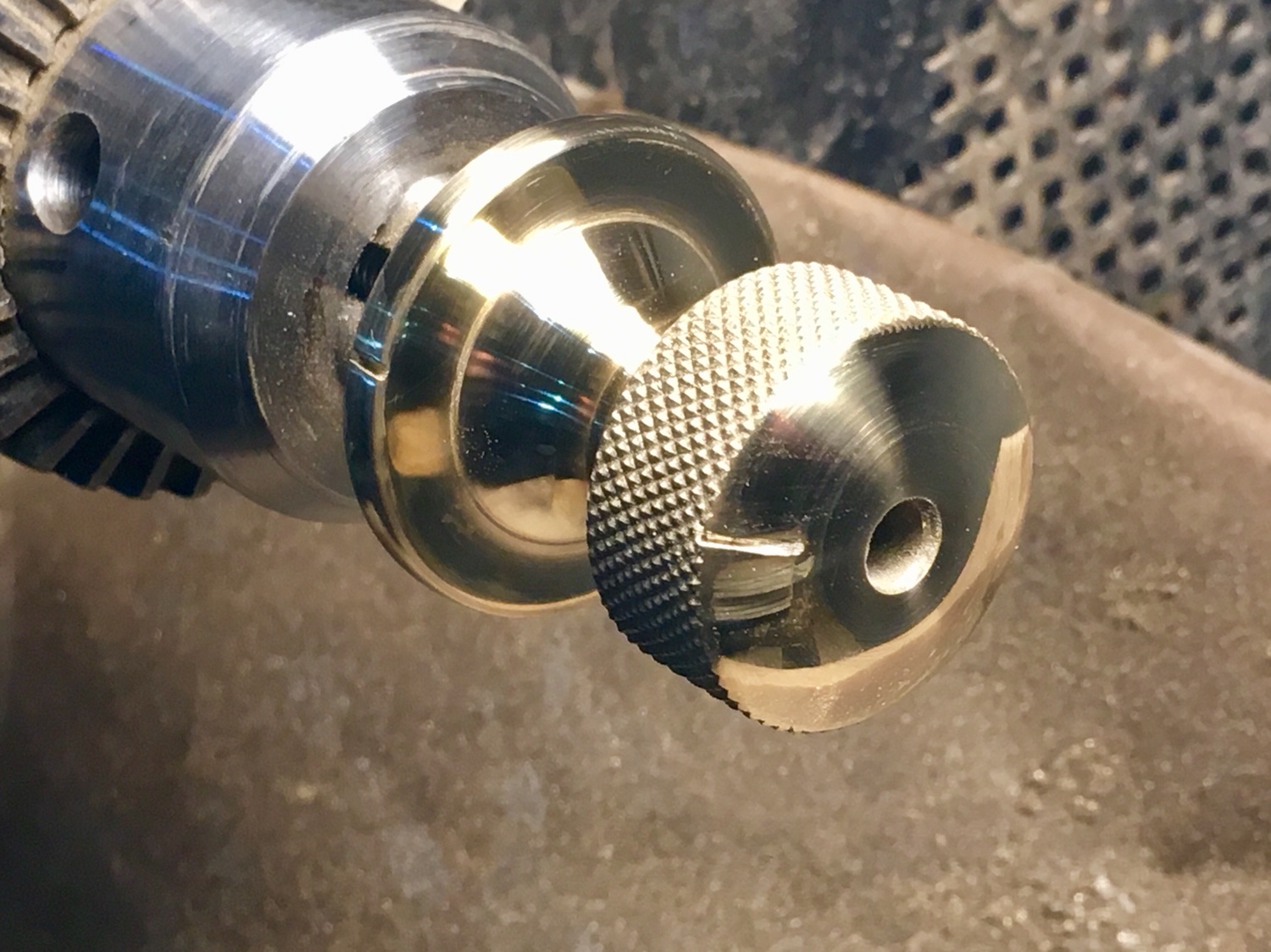

The knurled thumb nuts I bought are a pair of these on ebay

https://www.ebay.co.uk/itm/Brass-Knurle ... 2749.l2649

One is used for securing the blade clamp, the other I used for the height adjuster.

Note that I did polish up the thumb nut (not the knurled edge) by mounting the nut on an M6 threaded rod and used the OTT micro-grit pads again.

In the meantime I’d bought a couple of the Veritas router plane blades, so I had them for accurate sizing. For the depth stop I bought a short length of 22mm diameter brass rod from eBay. So as there was a lot of experimentation during this build I thought I’d try and drill a hole into the rod using the wood lathe, so I mounted the rod in my chuck using the centre of the jaws to secure the rod (hopefully) central. I then drilled a small hole (maybe 4mm) and then worked up from 6mm to 8mm and finally to a 10mm diameter hole - also used 3 in 1 for lubrication, rightly or wrongly!

Once I drilled the hole I did a little shaping of what would be the top face of the depth stop using a file while the lathe was on. The i sanded it using the micro-grit pads.

In order to cut it off, again rightly or wrongly, I carefully moved a hacksaw forwards while the lathe was on in order to cut the correct length almost all the way through, but tuned off when I was close to actually saw the rest off with the hacksaw properly. Note that I found it a cleaner/slower/less scary cut with the teeth of the hacksaw blade facing the wrong way.

I cleaned up the burrs to the bottom face of the depth stop using sand paper, working my way through the grits by rubbing on my table saw table, and even went through the micro-grit pads to an unnecessary 12000 grit.

I have some cheapy small files which I randomly received among random tools that came with my lathe, which I used to try to form internal corners of the hole in the depth stop to try and make a nicely fitting square hole the right size for the Veritas blades, which took a while.

[As a side note, I bought a second cut and smooth cut Bahco 10mm square files (which are great by the way!) for this and for making the V-groove in the body, but I wish I’d gone for the 8mm square files as the 10mm files were too big to use effectively until the hole was already big enough for the depth stop, so I was only able to use the top tapered area of the files.]

Anyway, got there in the end and then drilled and tapped a hole for an M4 knurled bolt (which I got here... https://www.amazon.co.uk/gp/product/B07 ... UTF8&psc=1 - again, a lot more than I need, but will no doubt come in handy for future projects in years to come)

As you can tell from the above and below photos, the hole isn’t the tidiest and was actually a little too big/loose for my liking as it wobbled to either side of the knurled bolt a bit when tightened(so would be too inaccurate for me as a depth stop), so this was my first attempt and I have since made another tidier, better fitting one.

So on to the blade clamp...

So I bought this eye bolt from eBay

https://www.ebay.co.uk/itm/2-Pack-M6-Th ... 1438.l2649

As it actually gave the inside diameter as 10mm, which is needed for the blades. So similarly to the depth stop above, I used a combination of the small files and the top tapered end of the 10mm square Bahco files to form a nicely fitting square hole for the blades.

The knurled thumb nuts I bought are a pair of these on ebay

https://www.ebay.co.uk/itm/Brass-Knurle ... 2749.l2649

One is used for securing the blade clamp, the other I used for the height adjuster.

Note that I did polish up the thumb nut (not the knurled edge) by mounting the nut on an M6 threaded rod and used the OTT micro-grit pads again.