dedee

Established Member

I'm not going to debate the merits of one bench over another, of aprons, tails vices or any other add on.

I put this together earlier in the year based on the "Chapman" bench.

A M&T Frame at each end, chipboard back to stop racking, chipboard lower shelf also aids stability, frames also have panels screwed to them to add rigidity.

Top 1" chipboard, and 3 18mm MDF lipped with beech.

NB No fixed vices

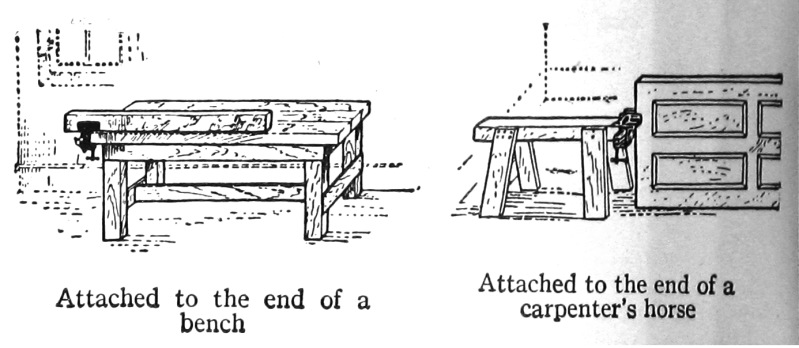

Dog holes in the top for surface planing. Edge planing curtesy of a couple of wotsits (sorry Bugbear I've forgotten what you called them)

surface planing

I can clamp a "lathe" to it

A Gripmaster also comes in handy

Metal work vice

Simple and cheap to make, versatile in use.

Cheers

Andy

I put this together earlier in the year based on the "Chapman" bench.

A M&T Frame at each end, chipboard back to stop racking, chipboard lower shelf also aids stability, frames also have panels screwed to them to add rigidity.

Top 1" chipboard, and 3 18mm MDF lipped with beech.

NB No fixed vices

Dog holes in the top for surface planing. Edge planing curtesy of a couple of wotsits (sorry Bugbear I've forgotten what you called them)

surface planing

I can clamp a "lathe" to it

A Gripmaster also comes in handy

Metal work vice

Simple and cheap to make, versatile in use.

Cheers

Andy