StevieB

Established Member

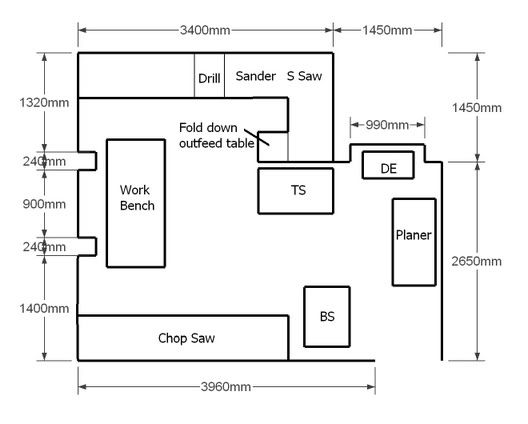

Trying to rejig the layout of my workshop on paper at the moment and am running into the problem of where to locate the tablesaw. I can either place it in the centre of the workshop, which is a pain because it eats space, or on or towards one wall. For those of you that do not have your TS in the middle of the floor, do you find the lack of an outfeed table a problem, and how much room do members generally feel is sufficient to the RHS of the blade and behind the blade? I do not cut full sheets, and rarely half sheets. Saw will almost certainly be on wheels of some description for the times I do need to.

I have a kity 419, table size is 600 deep x 400 wide, with up to two additional RHS extensions of 300mm each to make 1M total width. Would love to keep both extensions since using only 1 means cutting the long rails, but I am struggling to fit both in :roll:

Cheers,

Steve.

I have a kity 419, table size is 600 deep x 400 wide, with up to two additional RHS extensions of 300mm each to make 1M total width. Would love to keep both extensions since using only 1 means cutting the long rails, but I am struggling to fit both in :roll:

Cheers,

Steve.