Good day

Well, it's almost spring and I started to "warm-up" the machines..well, table saw and router table..that's all my "machines"

A few days ago I re-aligned the table saw blade, fence and sleds.

I don't have all this expensive equipment to align the blade to the miter slot so, I used a "Lo-tech" method just to bring the blade as parallel as I can, to the miter slot. I call it "Static alignment"

In my opinion, all the "Hi-tech" (and Hi-price) instruments can be "super-duper" accurate but, I think that the blade itself "knows" the best if it is aligned to the miter slot or not.

I call this check, "Dynamic alignment"...I just clamp a strip to the sled (or the miter gauge) and cut...when the strip reaches the back teeth, I listen to the noise...

If it's "cutting" noise, I know that I have to turn the blade clockwise.

If I don't here any noise, I know that I have to turn the blade counter-clockwise.

If I hear a "scratching" noise (I mean, the back teeth are just touching the strip) I know that the alignment is good.

Later, I check the fence alignment to the miter slot (Static check), rip some thin board and listen to the noise of the back teeth (Dynamic check)....and, same as above...

And as I know that, somebody will tell me "A post without pics is not a post".....(at least, not niki's post)...here are the piccies...

Regards

niki

And here is the "Dynamic test"

Listen to the noise of the back teeth

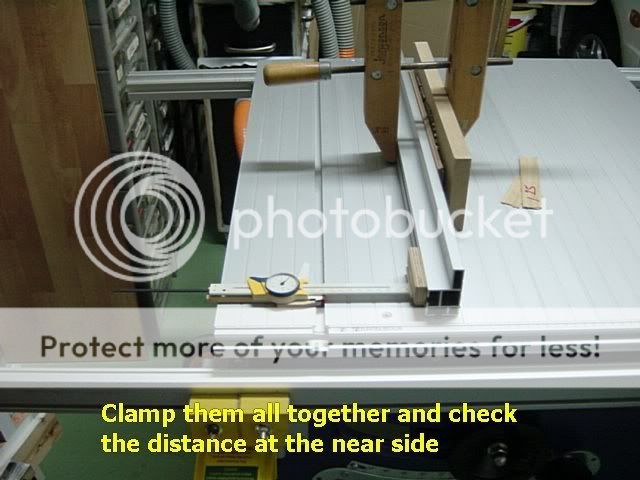

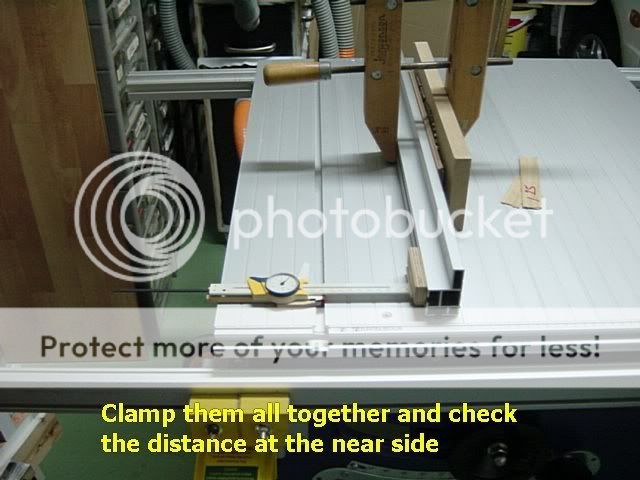

Bring the rip fence close to the miter slot and check the distances at one end...

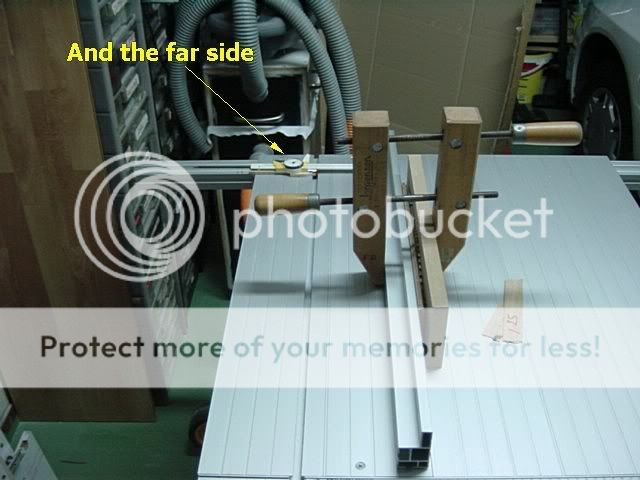

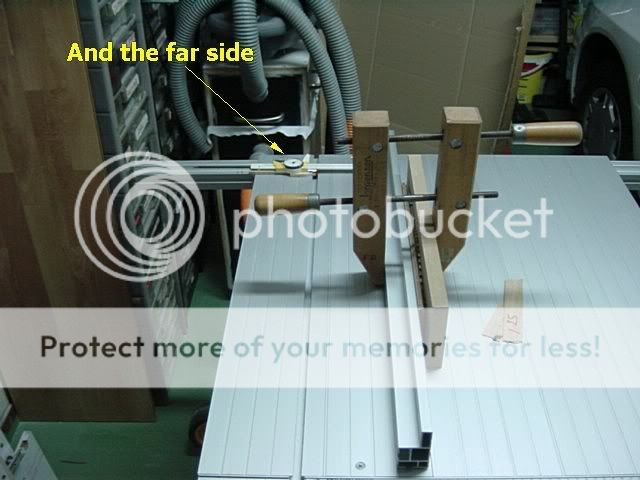

....And the other end

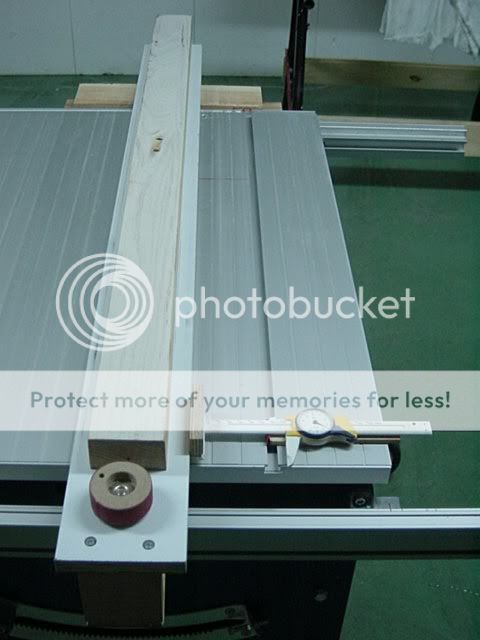

Cut a test piece and listen to the back teeth noise...

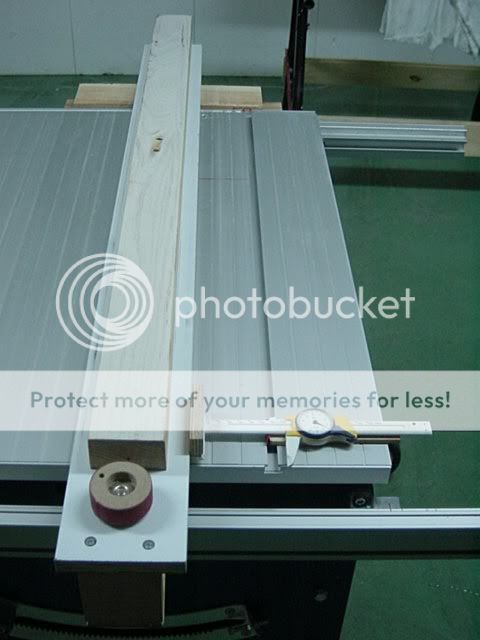

I do the same also on the long fence

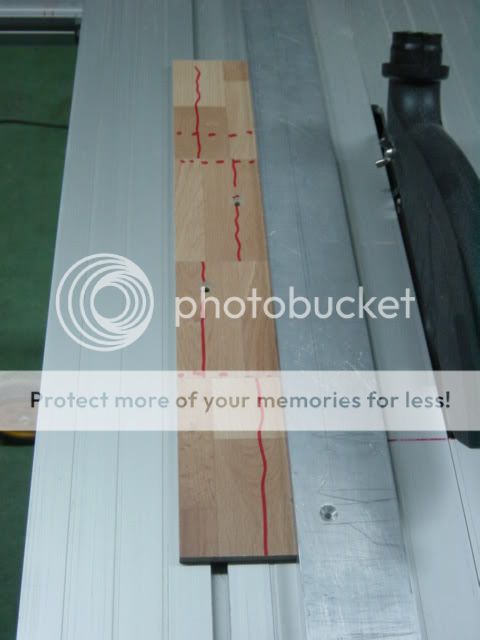

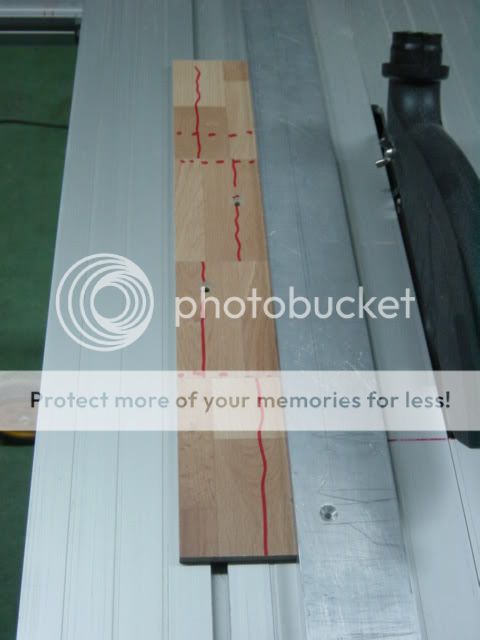

To check the squareness of the sled, I took a piece of thin board (floor panel)....

And cut it to 4 pieces

I alternate the pieces and checked them on a straight edge...any mistake will multiply itself...

Well, it's almost spring and I started to "warm-up" the machines..well, table saw and router table..that's all my "machines"

A few days ago I re-aligned the table saw blade, fence and sleds.

I don't have all this expensive equipment to align the blade to the miter slot so, I used a "Lo-tech" method just to bring the blade as parallel as I can, to the miter slot. I call it "Static alignment"

In my opinion, all the "Hi-tech" (and Hi-price) instruments can be "super-duper" accurate but, I think that the blade itself "knows" the best if it is aligned to the miter slot or not.

I call this check, "Dynamic alignment"...I just clamp a strip to the sled (or the miter gauge) and cut...when the strip reaches the back teeth, I listen to the noise...

If it's "cutting" noise, I know that I have to turn the blade clockwise.

If I don't here any noise, I know that I have to turn the blade counter-clockwise.

If I hear a "scratching" noise (I mean, the back teeth are just touching the strip) I know that the alignment is good.

Later, I check the fence alignment to the miter slot (Static check), rip some thin board and listen to the noise of the back teeth (Dynamic check)....and, same as above...

And as I know that, somebody will tell me "A post without pics is not a post".....(at least, not niki's post)...here are the piccies...

Regards

niki

And here is the "Dynamic test"

Listen to the noise of the back teeth

Bring the rip fence close to the miter slot and check the distances at one end...

....And the other end

Cut a test piece and listen to the back teeth noise...

I do the same also on the long fence

To check the squareness of the sled, I took a piece of thin board (floor panel)....

And cut it to 4 pieces

I alternate the pieces and checked them on a straight edge...any mistake will multiply itself...