A

Anonymous

Guest

MikeW":2xj22xti said:Now when was I going to update the OMG thread? ... :lol:

Take care, Mike

OMG ! :roll: :lol: worked out any clues to add yet ?

MikeW":2xj22xti said:Now when was I going to update the OMG thread? ... :lol:

Take care, Mike

Frank D.":16trzq0s said:If you want to simply glue the pieces together for a seamless joint, why bother using tongue and groove at all? Could it be for better alignment or more glue surface? Seems a lot of work for little gain(?)

Hi Shawn--not much better than to hear of success! We all smile when something works out.Wylie2112":1bp141ba said:I was also thinking that T&G helps prevent warping and better transfer of stress between the boards. Is that the case or no?

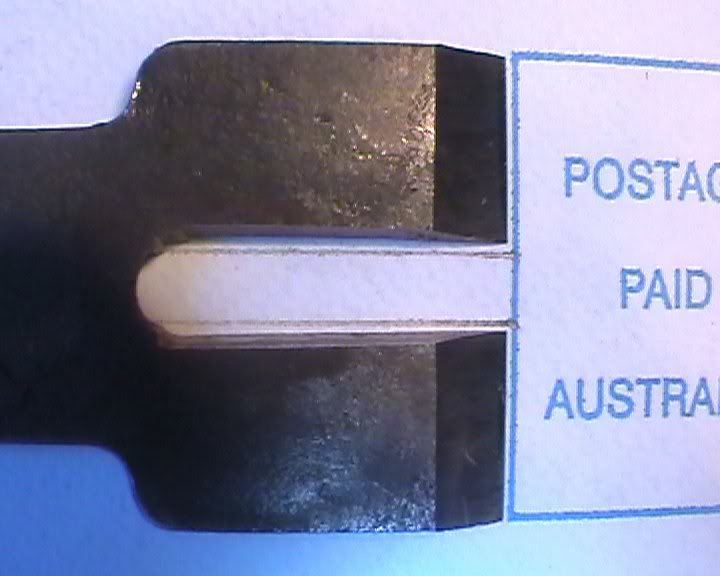

I did the obvious and put the chip deflector in BEFORE putting the tongue cutter in place and, guess what? It works a treat!! Completed my first tongue in just a few minutes after that. Now on to the groove!

Thanks again for the input, guys. Man there is a lot to learn! I feel like I'm just starting out on a learning path that will take a lifetime and not ever really stop.

Shawn

Wylie2112":1mrnjaak said:what kind of method would be adequate to give good alignment as well as a solid joint?

Wylie2112":3mgudq37 said:I did the obvious and put the chip deflector in BEFORE putting the tongue cutter in place and, guess what? It works a treat!! !

Mr_Grimsdale":1bm9tapw said:So much so that I wonder if combination planes are actually much used at all. Do they ever get used on a regular basis, or just as a stop gap for the odd job when something better is not available? Has anyone seen a well used one with signs of wear etc? They look a bit flimsy with lots of bits to lose.

Mr_Grimsdale":2y1d4qsm said:So much so that I wonder if combination planes are actually much used at all. Do they ever get used on a regular basis, or just as a stop gap for the odd job when something better is not available? Has anyone seen a well used one with signs of wear etc?

bugbear":2b7l0gw8 said:On the "wear" issue, to be honest (and IME), I've seen few planes other than the basic jacks and smoothers with clear signs of substantial wear. The cutting of joints and mouldings involves far less strenuous labour than stock prep. Even fore and jointer planes rarely show much wear.

BugBear

Jake Darvall":ywpjgamu said:bugbear":ywpjgamu said:On the "wear" issue, to be honest (and IME), I've seen few planes other than the basic jacks and smoothers with clear signs of substantial wear. The cutting of joints and mouldings involves far less strenuous labour than stock prep. Even fore and jointer planes rarely show much wear.

BugBear

:? Well, maybe I just use them more than you (which is odd, I didn't think I used them more than necessary). My comparison is between the wear of steel skates in combination planes to the equivelents in wooden planes.

Rounds can develop grooves in them pretty quick in front of the mouth from edge starts.....I have a small old one that had never been used prior to me owning it.......From my regular use its not looking good.

MikeW":3do6saxq said:I've used H&Rs a lot. Mine are a half set of Mosley & Sons. I have seen no wear, warpage or other damage in a bazillion years.

Same with my Preston chamfering plane, side beads, molders and moving fillister. I do wax the soles during use somewhat.

Take care, Mike

Wylie2112":321n44k7 said:Thanks for that tip on edge glueing or using an insert rather than T&G. May need to rethink the approach on this! Now that you guys have said all this, it does seem like unecessary work.

Paul Chapman":2vb9j69r said:Wylie2112":2vb9j69r said:Thanks for that tip on edge glueing or using an insert rather than T&G. May need to rethink the approach on this! Now that you guys have said all this, it does seem like unecessary work.

Apart from any strength issues, one of the reasons I like to use some sort of loose tongue is that it ensures the boards are perfectly aligned when you glue them up. It also makes the glue-up process much faster and less of a hassle and prevents the boards slipping about. If after glue-up you find that the boards are not properly aligned, you will have a lot of work planing them to get them flat.

In my time I've used plywood loose tongues and formed the grooves with a plane and an electric router. These days I use a biscuit jointer and biscuits. In effect it does the same job but so much faster and very accurate.

Hope this helps :wink:

Paul

Enter your email address to join: