Getting close to the finish now, I had my 2 halves of chair which needed bringing together. A test fit of the joints showed that they were a lot tighter than I remembered, combine this with my assistant being away and I knew I was in for some pain.

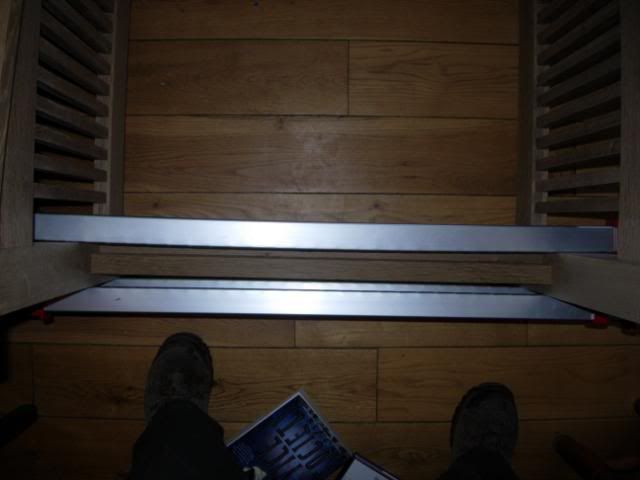

Went for the alu clamps again as they'd worked well before and are easier to manhandle on your own - think I pretty much tested them to the limit and should have gone for the steel ones. Took quite a while to get them in and a lot swearing, but finally had a chair shaped object.

You can see (just about) that I was on the limit for these clamps, as they had a visible bend in them.

Before going to the finish I knew I had to effect a small repair at the top of the legs on one side. I was struggling to get a perfect fit when assembling leg, rail and arm, the key problem being a slight bow in the length of the rail that had appeared over a period of months. Almost imperceptible but it was there and nothing I could do about it. The upshot was that there was a slight gap at the top of the legs where they met the arm, approx 1mm at the back and 1.5mm at the front. I could have tried removing bits of wood in the joints to try and fix, but my worry was that I'd end up with a sloppy joint, at least I could have a (very) tight joint with repairable gap.

This is where my set of legs that went wrong came in handy, cleaned up a section and took one to the tablesaw, removing 2 very thin slivers that just needed trimming to fit. This was the end result, not too bad and in a spot that in normal use won't get seen - but I would have known was there

You can also see another of the oak dowels there. That Clico forstner really is the dogs danglies, perfect holes every time and there were 30-40 across the chair and stool.

Finish was with Liberon Superior Danish Oil after sanding to 320 grit. Pictures here are after coat number 4 and it's coming out beautifully. Next coat is to be applied with 320 grit paper to smooth and fill and pores that might still be open (this oak has been pretty thirsty), final coat is to be number 6 which will be applied after it comes back from the upholsterer to have to cushions made and fitted. The upholsterer is a local chap who is an ex-student of Leeds College, his website shows some pretty impressive pieces.

You can see from the pics that I was trial fitting the back, this showed I needed to sand down the washers a little and gave me the correct length for the pivot and adjustment pins. Hopefully the next time you see this it will have the final finish and cushions - aiming to get it done in time to display at the college's end of year show