devonwoody

Established Member

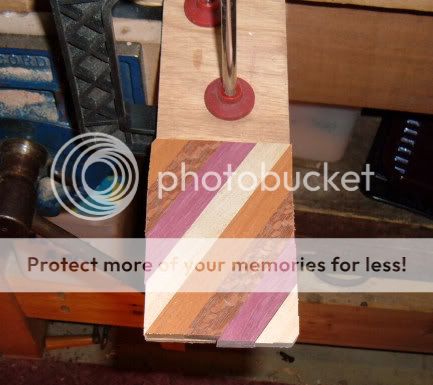

Some Australian forum member used a cad program and gave me measurements for a chevron pattern box, dimensions to be 9x 4 1/2x3".

I printed out the pattern and decided to make box using my traditional strip concept. I would admit this is against advice received but cutting and planing pieces would have been a bit small for working with machinery.

So you can see the design laying on the desk in picture below.

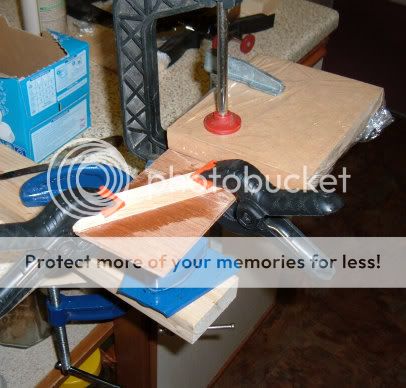

I have cut ply base templates to size.

Preparing the 4 timbers to be used, Sycamore, lacewood, purple heart and meranti.

Got some heat going in the workshop.

Marked up one of the ply base templates in pencil and fixed to the vice.

Cut the first chevron to fit. knocked up a cutting piece by trial an error on the mitre drop saw, then fitted the sample cutting to my mitre gauge on the tablesaw and cut the first chevron.

Cut the other end of the chevron by hand (not so critical a cut) using my sawbench with battens screwed down to maintain angles.

Two sessions of work above.

But not staying in workshop very long with conditions like these.

I printed out the pattern and decided to make box using my traditional strip concept. I would admit this is against advice received but cutting and planing pieces would have been a bit small for working with machinery.

So you can see the design laying on the desk in picture below.

I have cut ply base templates to size.

Preparing the 4 timbers to be used, Sycamore, lacewood, purple heart and meranti.

Got some heat going in the workshop.

Marked up one of the ply base templates in pencil and fixed to the vice.

Cut the first chevron to fit. knocked up a cutting piece by trial an error on the mitre drop saw, then fitted the sample cutting to my mitre gauge on the tablesaw and cut the first chevron.

Cut the other end of the chevron by hand (not so critical a cut) using my sawbench with battens screwed down to maintain angles.

Two sessions of work above.

But not staying in workshop very long with conditions like these.