Mreagleeyes

Established Member

Hello folks.

This is a sort of continuation from Matt_S post.

https://www.ukworkshop.co.uk/forums/desk-shelving-unit-t40172.html

Thanks to Matt, Paul & Simon (Oryxdesign) for the previous help from the post above.

I'll give you a call Simon before putting the coloured coat on.

This is my take on assembling & spraying MDF using the Earlex Spray system from Argos and paint from Morrells in Park Royal.

The spray system.

As a first time sprayer I thought I would go with a cheap system and see how I got on.

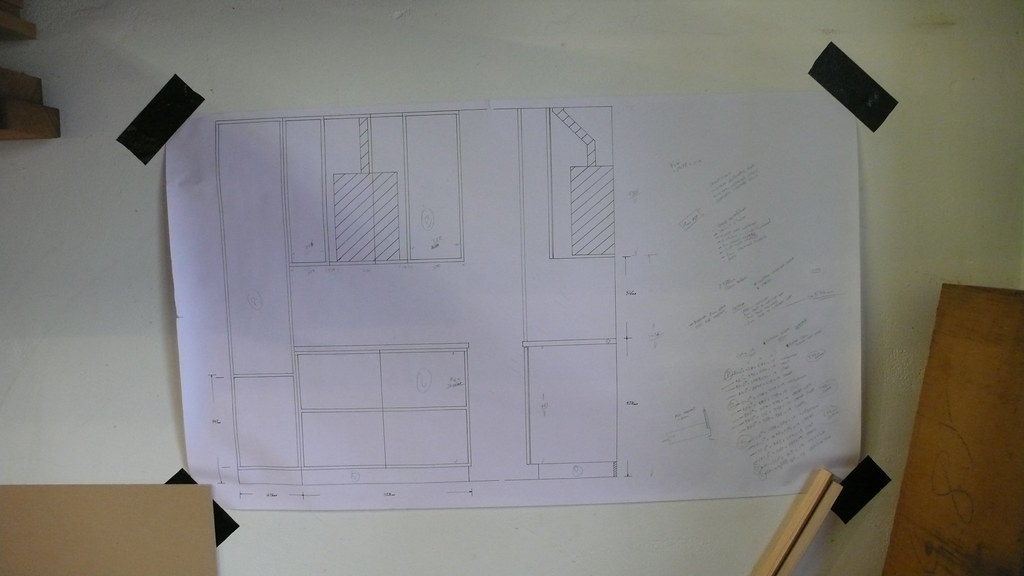

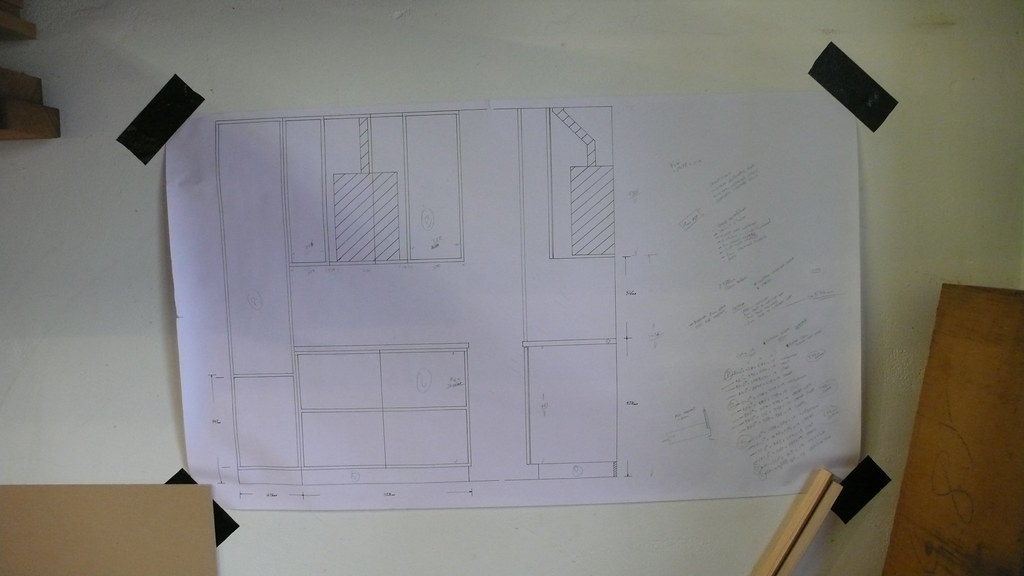

The drawings.

Incorporating a boiler in the top right unit.

The lower large unit.

Constructed using 19mm MDF and the good old Domino and screws. Titebond III through out. Could have done with a few more clamps but didn't have any more so had to do with 4.

Detailed section.

I decided to use the dominos as shelf supports like Matt had done from the previous thread and was unsure whether to spray with the dominos in place or spray with them removed, in the end I removed them.

I cut a 10mm 'slot' in the back edges to take the 6mm backing board.

The mistake.

Always check the machines for depth of cut. With so many varying depths of cut with the domino because of the 19mm MDF and whether your cutting in face or edge. A lesson learned.

The spray kit and paint.

The units

Preparing for spraying. I machine sanded all faces with the palm sander before construction using Grits from 160 - 240. I then gave a hand finish to bevel all edges and get rid of any glue and pencils marks.

Glue

I wish that I had used the smaller of the dominos as the 6mm seem very large.

My spraying process

The bowl on the left contains the Thinners and I used this to clean out the sprayer and also store the needle of the sprayer over night. I could simply come in the following morning and assemble the 'gun' again with all components cleaned and ready to go.

I had to lightly clamp down the motor for the sprayer as once it's going it had a mind of it's own. A relatively noisy machine I thought.

Dust dust dust!!!.

It gets everywhere. I was going to build a sort of sheeted booth but thought in the end that I would just give the place a good clean once finished.

And so does the paint.

Unfortunately not in a position to have a design room and also a workshop so I just get on with it. Think a bit of paint adds some character to a workshop.

First coat.

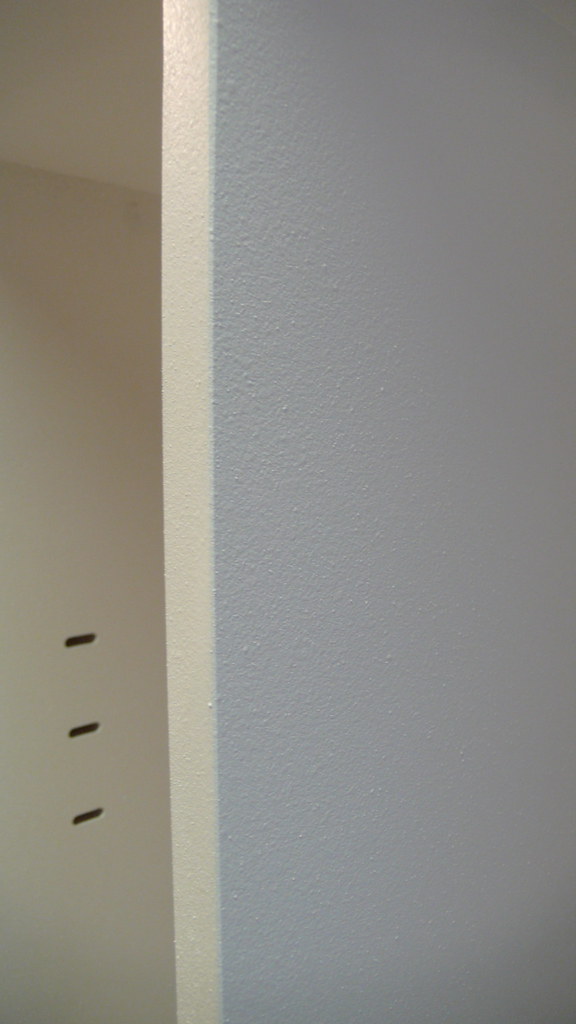

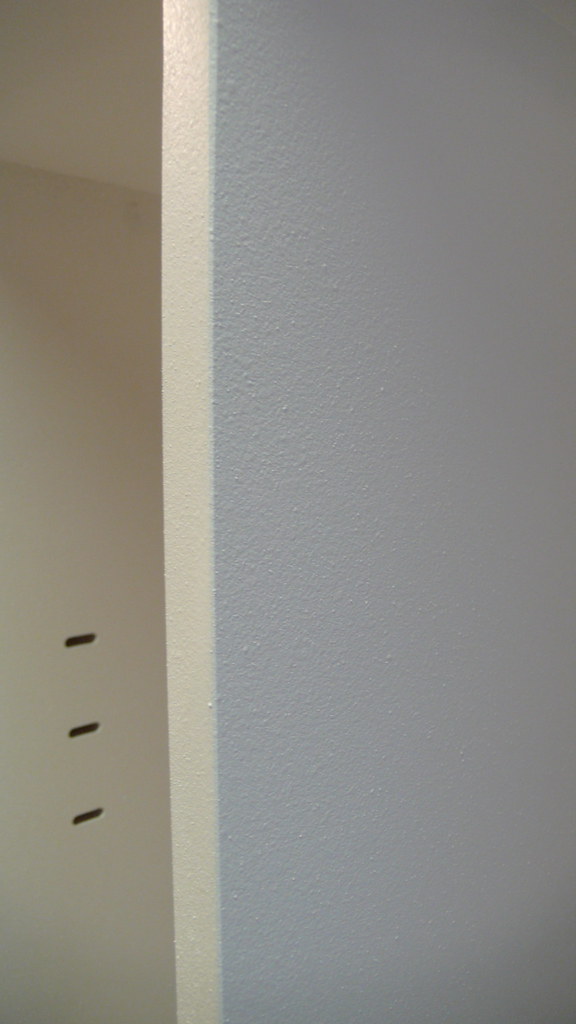

With other unit underneath and backing board to the right. Be aware of how you store the MDF, I was noticing that it was bowing slightly as I had stored it on edge leaning against the wall. I have since moved all components to a flat area.

Second coat Prior to sanding!!.

This makes it look awful but once sanded lightly I get a good clean finish that I'm happy with, If I'm wrong let me know.

I did discover that the spray system sometimes seemed to 'spit' the paint out and give large paint mark drops, as above. I'm hoping that once I get the hang of it for the final 2 colour coats I should have it in order.

I would be interested to find out the best method for finishing the surface, be that ScotchBrite, 1500 wet & dry or even a polishing process to give the surface a clean flat surface.

Preparing the shelves.

The most important thing.

A good mask, the fumes get everywhere and even walking in to the yard the following morning I could smell the fumes in the air. The dog is with dad till I get these units out.

So first impressions. I find that for £50 you can't go wrong on the spray system and as an introduction to spraying it does the job.

The paint is relatively expensive, I have used just under 5 ltrs on the 2 units and back panels, there is still the large unit to make and spray but that's for tomorrow.

The domino has proved once again why it is such a great machine, all faces are perfectly square with each other and the precision of the repeated cuts that I got with the shelf supports makes it a top tool.

The primer dries in about 15 minutes, though I gave it 30 minutes as I got a little too keen at one stage and sanded though the dry section to the wet underneath and ended up with paint filled sandpaper. All a learning curve.

So just the large unit & doors to construct and spray and then the final coats of the clients colour, they are still undecided.

I am still undecided on how the units will be fixed to the breeze block wall, maybe some small corner pieces that I could screw into the inside corners and then in turn screw to the walls.

I'll keep this post updated until completion. Thanks for looking and that's all folks for the time being.

Patrick

This is a sort of continuation from Matt_S post.

https://www.ukworkshop.co.uk/forums/desk-shelving-unit-t40172.html

Thanks to Matt, Paul & Simon (Oryxdesign) for the previous help from the post above.

I'll give you a call Simon before putting the coloured coat on.

This is my take on assembling & spraying MDF using the Earlex Spray system from Argos and paint from Morrells in Park Royal.

The spray system.

As a first time sprayer I thought I would go with a cheap system and see how I got on.

The drawings.

Incorporating a boiler in the top right unit.

The lower large unit.

Constructed using 19mm MDF and the good old Domino and screws. Titebond III through out. Could have done with a few more clamps but didn't have any more so had to do with 4.

Detailed section.

I decided to use the dominos as shelf supports like Matt had done from the previous thread and was unsure whether to spray with the dominos in place or spray with them removed, in the end I removed them.

I cut a 10mm 'slot' in the back edges to take the 6mm backing board.

The mistake.

Always check the machines for depth of cut. With so many varying depths of cut with the domino because of the 19mm MDF and whether your cutting in face or edge. A lesson learned.

The spray kit and paint.

The units

Preparing for spraying. I machine sanded all faces with the palm sander before construction using Grits from 160 - 240. I then gave a hand finish to bevel all edges and get rid of any glue and pencils marks.

Glue

I wish that I had used the smaller of the dominos as the 6mm seem very large.

My spraying process

The bowl on the left contains the Thinners and I used this to clean out the sprayer and also store the needle of the sprayer over night. I could simply come in the following morning and assemble the 'gun' again with all components cleaned and ready to go.

I had to lightly clamp down the motor for the sprayer as once it's going it had a mind of it's own. A relatively noisy machine I thought.

Dust dust dust!!!.

It gets everywhere. I was going to build a sort of sheeted booth but thought in the end that I would just give the place a good clean once finished.

And so does the paint.

Unfortunately not in a position to have a design room and also a workshop so I just get on with it. Think a bit of paint adds some character to a workshop.

First coat.

With other unit underneath and backing board to the right. Be aware of how you store the MDF, I was noticing that it was bowing slightly as I had stored it on edge leaning against the wall. I have since moved all components to a flat area.

Second coat Prior to sanding!!.

This makes it look awful but once sanded lightly I get a good clean finish that I'm happy with, If I'm wrong let me know.

I did discover that the spray system sometimes seemed to 'spit' the paint out and give large paint mark drops, as above. I'm hoping that once I get the hang of it for the final 2 colour coats I should have it in order.

I would be interested to find out the best method for finishing the surface, be that ScotchBrite, 1500 wet & dry or even a polishing process to give the surface a clean flat surface.

Preparing the shelves.

The most important thing.

A good mask, the fumes get everywhere and even walking in to the yard the following morning I could smell the fumes in the air. The dog is with dad till I get these units out.

So first impressions. I find that for £50 you can't go wrong on the spray system and as an introduction to spraying it does the job.

The paint is relatively expensive, I have used just under 5 ltrs on the 2 units and back panels, there is still the large unit to make and spray but that's for tomorrow.

The domino has proved once again why it is such a great machine, all faces are perfectly square with each other and the precision of the repeated cuts that I got with the shelf supports makes it a top tool.

The primer dries in about 15 minutes, though I gave it 30 minutes as I got a little too keen at one stage and sanded though the dry section to the wet underneath and ended up with paint filled sandpaper. All a learning curve.

So just the large unit & doors to construct and spray and then the final coats of the clients colour, they are still undecided.

I am still undecided on how the units will be fixed to the breeze block wall, maybe some small corner pieces that I could screw into the inside corners and then in turn screw to the walls.

I'll keep this post updated until completion. Thanks for looking and that's all folks for the time being.

Patrick